Industrial Process Water Chiller for Cooling Raycus High Power 6000W Fiber Laser

Product Description

S&A Teyu industrial process water chiller CWFL-6000 is suitable to cool 6000W high power fiber lasers of different brands, including Raycus, IPG and so on.

Dual temperature chillers CWFL-6000,specially designed for cooling 6000W fiber lasers, are characterized by dual circulating refrigeration system and dual temperature control system.

1. With environmental refrigerant;

2. ±1℃ precise temperature control;

3. The intelligent temperature controller has 2 control modes, applicable to different applied occasions; with various setting and display functions;

4. Dual temperature to satisfy different needs of fiber laser device and the optics;

5. With Ion adsorption filtrating and test functions conform to fiber laser device operating requirements;

6. Multiple alarm functions: compressor time-delay protection, compressor overcurrent protection, water flow alarm and over high / low temperature alarm;

7. Multiple power specifications; CE approval; RoHS approval; REACH approval;

8. Optional heater and water filter.

9. Support Modbus-485 communication protocol, which can realize the communication between the laser system and multiple water chillers to achieve two functions: monitoring the working status of the chillers and modifying the parameters of the chillers.

THE WARRANTY IS 2 YEARS AND THE PRODUCT IS UNDERWRITTEN BY INSURANCE COMPANY.

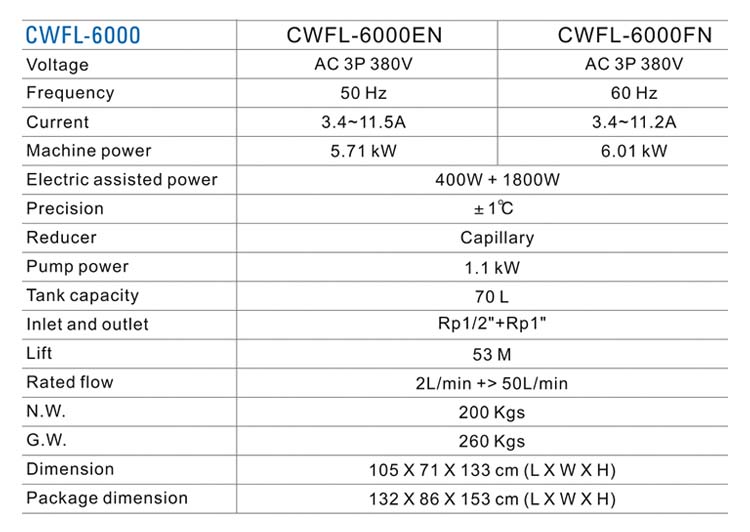

Dual temperature chillers specification

Note: the working current can be different under different working conditions; The above information is for reference only. Please subject to the actual delivered product.

PRODUCT INTRODUCTION

Independent production of sheet metal, evaporator and condenser

Adopt IPG fiber laser for welding and cutting sheet metal.

Temperature control accuracy can reach ±1℃. High temp. for QBH connector/optics and low temp. for laser device.

Equipped with water pressure gauges ,drain outlet and universal wheels.

Dual inlet and dual outlet connector equipped.

Chiller inlet connects to laser outlet connector. Chiller outlet connects to laser inlet connector.

Level gauge equipped

Cooling fan of famous brand installed.

Customized dust gauze available and easy to take apart

Annual production capacity of 60,000 units, focus on large, medium and small power chiller production and manufacture.

Video

S&A Teyu industrial water chiller CWFL-6000 video

How to set water temperature for T-507 temperature controller of dual temp chiller

S&A Teyu water chiller CWFL-6000 for all cover exchange fiber laser cutting machine

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.