Industrial chiller is an important machine used for heat dissipation and refrigeration in industrial equipment. When installing chiller equipment, users should pay attention to the specific precautions for installation and use to ensure normal operation of the equipment and normal cooling.

Industrial water chiller installation and use precautions

Industrial chiller is an important machine used for heat dissipation and refrigeration in industrial equipment. When installing chiller equipment, users should pay attention to the specific precautions for installation and use to ensure normal operation of the equipment and normal cooling.

1. Installation Precautions

Industrial chillers have certain requirements for installation:

(1) It must be installed horizontally and cannot be tilted.

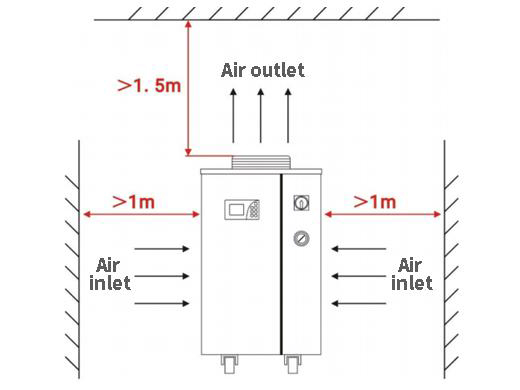

(2) Keep away from obstacles. The air outlet of the chiller should be kept at least 1.5m away from the obstacle, and the air inlet should be at least 1m away from the obstacle.

Installation Precautions For Air Inlet And Outlet

(3) Do not install in harsh environments such as corrosive, flammable gas, dust, oil mist, conductive dust, high temperature and humidity, strong magnetic field, direct sunlight, etc.

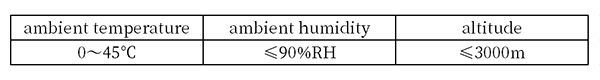

(4) Environmental requirements Ambient temperature, ambient humidity, altitude.

Installation Environment Requirements

(5) Medium's requirements. The cooling medium allowed by the chiller: purified water, distilled water, high-purity water and other softened water. The use of oily liquids, liquids containing solid particles, corrosive liquids, etc. is prohibited. Regularly (recommended about three months) clean the filter element and replace the cooling water to ensure the normal operation of the chiller.

2. Precautions for start-up operation

When the industrial chiller is running for the first time, it is necessary to add appropriate cooling water to the water tank, observe the water level gauge, and it is appropriate to reach the green area. There is air in the waterway. After ten minutes of operation for the first time, the water level will drop, and it is necessary to add circulating water again. In the subsequent start-up, it is also necessary to pay attention to whether the water level is in a suitable area to avoid running without water, resulting in dry grinding of the pump.

3. Operation precautions

Observe whether the chiller is in operation, the thermostat displays, whether the cooling water temperature is normal, and whether there is any abnormal noise in the chiller.

The above are the precautions for the installation and operation of the chiller summarized by the engineers of S&A's chiller. I hope it will be helpful to you.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.