Heater

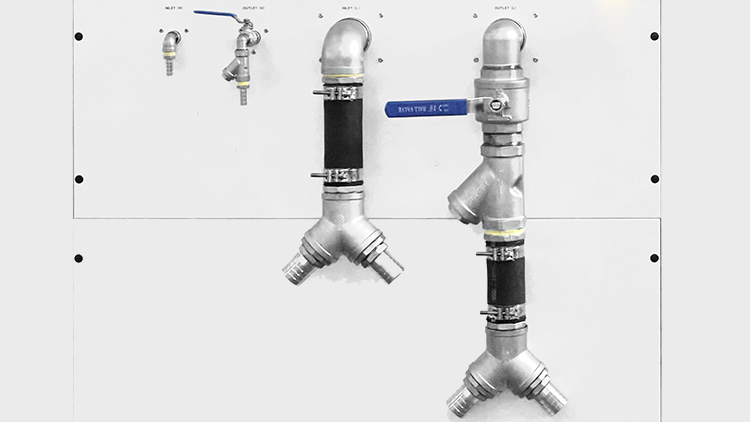

Filter

Driven by a keen understanding of market dynamics, TEYU Fiber Laser Chiller Manufacturer is thrilled to unveil our new product - Ultrahigh Power Fiber Laser Chiller CWFL-120000. Meticulously designed for high reliability, high performance and high intelligence, laser chiller CWFL-120000 is ideal for cooling 120kW fiber laser sources, showcasing industry-leading capabilities.

120kW fiber laser chiller CWFL-120000 integrates dual cooling circuits designed for the laser and the optics, providing a dual protection effect on the laser cutting equipment, gradually optimizing energy efficiency through distinct temperature regulation during long-term operation. The design of the ModBus-485 communication adds a layer of convenience, enhancing connectivity and control for seamless operation. It also comes with multiple alarm functions for all-around protection for both the laser chiller and the fiber laser machine. Customization is available.

Model: CWFL-120000

Machine Size: 340 × 139 × 190 cm (L × W × H) + 340 × 139 × 190 cm (L × W × H)

Warranty: 2 years

Application: for 120kW Fiber Laser

| Model | CWFL-120000ETTY | |

| Main | Auxiliary | |

| Voltage | AC 3P 380V | AC 3P 380V |

| Frequency | 50Hz | 50Hz |

| Current | 34.3~132.5A | 34.3~132.5A |

| Max. power consumption | 66.88kW | 66.88kW |

| Heater power | 10.8kW+1.8kW | 10.8kW+1.8kW |

| Precision | ±1.5℃ | ±1.5℃ |

| Reducer | Capillary | Capillary |

| Pump power | 5.5kW+5.5kW | 5.5kW+5.5kW |

| Tank capacity | 600L | 600L |

| Inlet and outlet | Rp 1/2"+Rp 2"*2 | Rp 1/2"+Rp 2"*2 |

| Max. pump pressure | 7 bar | 7 bar |

| Rated flow | 10L/min+>600L/min | 10L/min+>600L/min |

| N.W. | 1305kg | 1305kg |

| G.W. | 1648kg | 1648kg |

| Dimension | 340 × 139 × 190 cm (L × W × H) | 340 × 139 × 190 cm (L × W × H) |

| Package dimension | 355 × 163 × 214 cm (L × W × H) | 355 × 163 × 214 cm (L × W × H) |

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Dual cooling circuit

* Active cooling

* Temperature stability: ±1.5°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410A/R-32

* Intelligent digital control panel

* Integrated alarm functions

* Back mounted fill port and easy-to-read water level check

* RS-485 Modbus communication function

* High reliability, energy efficiency and durability

* Available in 380V

Heater

Filter

Dual temperature control

The intelligent control panel offers two independent temperature control systems. One is for controlling the temperature of the fiber laser and the other is for controlling the optics.

Dual water inlet and water outlet

Water inlets and water outlets are made from stainless steel to prevent potential corrosion or water leakage.

Junction Box

Professionally designed by engineers from TEYU chiller manufacturers, easy and stable wiring.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.