Is it air cooling the perfect way to cool UV LED curing unit?

As we know, the core component of UV LED curing unit is the UV LED light source and it needs proper cooling in order to function normally. There are two cooling methods for cooling UV LED. One is air cooling and the other is water cooling. Whether to use water cooling or air cooling depends on the power of the UV LED light source. Generally speaking, air cooling is applied more often in low power UV LED light source while water cooling is applied more often in middle or high UV LED light source. Besides, the specification of the UV LED curing unit generally indicates the cooling method, so users can follow the specification accordingly.

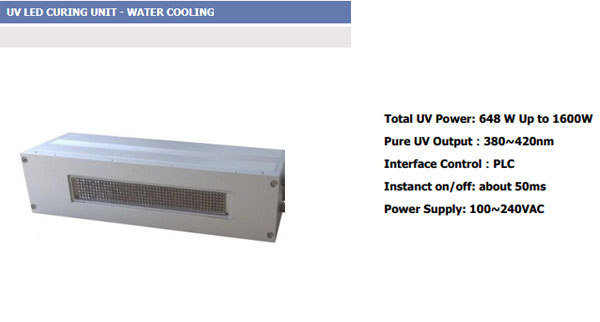

For example, in the following specification, the UV LED curing unit uses water cooling system as the cooling method. The UV power ranges from 648W to 1600W. In this range, there are two S&A Teyu water cooling chillers are the most suitable.

The other is S&A Teyu water cooling chiller CW-6000, whcih is suitable to cool 1.6KW-2.5KW UV LED light source. It has 3000W cooling capacity and ±0.5℃ temperature stability, which can perform precise temperature control to the UV LED light source.

To learn more about S&A Teyu water cooling chillers of the above mentioned models, please click https://www.teyuchiller.com/industrial-process-chiller_c4