Laser welding and laser soldering are two distinct processes with varying working principles, applicable materials, and industrial applications. But their cooling system "laser chiller" can be the same - TEYU CWFL series fiber laser chiller, intelligent temperature control, stable and efficient cooling, can be used to cool both laser welding machines and laser soldering machines.

Differences Between Laser Welding & Soldering And Their Cooling System

Laser welding and laser soldering are two distinct processes with varying working principles, applicable materials and industrial applications. But their cooling system "laser chiller" can be the same: TEYU industrial water chillers can be used to cool both laser welding and soldering machines.

The Working Principles Are Different

Laser soldering employs the high energy density of a laser to achieve localized or micro-regional heating to complete the welding process. In contrast, laser welding focuses on precise control of laser power distribution. While both rely on laser beams as heat sources, they differ technically.

Laser welding is a form of laser processing. It uses the laser as a heat source to radiate the leads (or the connection pads of leadless devices), and transfer the heat to the substrate using laser welding-specific solders such as laser solder paste, solder wire, or prefabricated solder sheets. When the solder's melting point is attained, it melts and wets the substrate and leads to form a joint. Laser welding uses high-energy laser pulses to heat small areas of material locally. The laser radiation's energy diffuses into the material through heat conduction, melting it to form a specific molten pool.

Applicable Materials and Application Fields for Laser Soldering

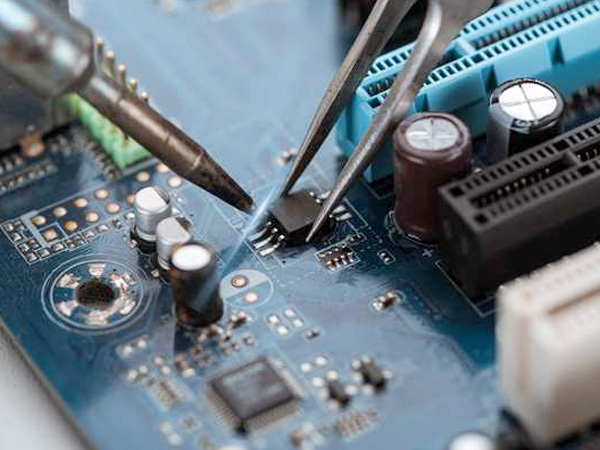

Laser soldering machines can effectively solder materials such as post-mounted plug-ins, temperature-sensitive components, difficult-to-solder components, micro-speakers/motors, SMT post-welding of various PCBs, mobile phone components, etc.

Applicable Materials and Application Fields for Laser Welding

Laser welding machine can be used to weld metals and plastics. It is widely used in a variety of fields such as batteries, solar energy, mobile phone communications, optical fiber communicators, molds, electronic appliances, IC integrated appliances, instruments and meters, gold and silver jewelry, precision devices, aerospace devices, the automobile industry, and the electrical industry.

Industrial Water Chillers for Cooling Laser Soldering and Laser Welding Machines

When it comes to laser soldering and laser welding, precise temperature control is crucial for optimal performance. As lasers are highly sensitive to temperature, stable temperature control can result in refined welding and higher yields.

TEYU industrial water chiller is an excellent temperature control helper that is specifically designed for laser soldering and welding equipment. With dual independent temperature control mode, the high-temperature control mode cools the laser head and the low-temperature control mode cools the laser itself. Additionally, this laser chiller can save installation space. The temperature stability of laser chillers reaches up to ±0.1℃. Its precise temperature control ensures efficient refrigeration during laser welding and solder processing, thereby improving operational efficiency and prolonging the service life of the equipment.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.