I-Metal laser cutting ingenye yezinhlelo zokusebenza ezibaluleke kakhulu zokucutshungulwa kwe-laser. Ngokuthuthukiswa kwezinqubo ze-fiber laser, umshini wokusika wensimbi we-laser uzothatha kancane kancane indawo yedivayisi yokusika yensimbi yendabuko.

Ukusika kwe-metal laser kuhluke kakhulu ekusikeni kwensimbi yendabuko kumgomo wokusebenza. Ukusika kwe-laser yensimbi kubonisa ukuthumela i-laser light beam ebusweni bengxenye yensimbi. Khona-ke ingxenye yensimbi iyoncibilika noma ihwamuke ukuze injongo yokusika nokuqopha igcwaliseke. Ukusika i-laser kunezinzuzo eziningi, njengejubane eliphezulu, ukonga impahla, izindleko eziphansi zokusebenza kanye nokusika okushelelayo/imiphetho yokuqopha.

Ngokusekelwe kumgomo wokusebenza, ukusika kwe-laser yensimbi kungahlukaniswa ngezinhlobo ezi-3:

1.Ukusika ngokusebenzisa ukuhwamuka

Lokhu kubonisa ukusebenzisa amandla aphezulu kanye ne-high density laser beam ukushisisa insimbi. Ingxenye yensimbi emunca i-laser beam izohwamuka esikhathini esifushane futhi ibe umhwamuko, ishiye ukusikeka endaweni yensimbi. Njengoba ukushisa kokuhwamuka ngokuvamile kukhulu, lolu hlobo lokusika kwe-laser ludinga ugongolo lwe-laser lwamandla aphezulu kanye nokuminyana okuphezulu.

2.Ukusika ngokuncibilika

Ngalolu hlobo lokusika kwe-laser, izinto zensimbi zizoncibilika ngemuva kokumunca ukushisa okuvela ku-laser. Idinga kuphela amandla angu-1/10 ohlobo lokuqala lokusika. Isetshenziswa kakhulu ukusika izinsimbi ezingaxubeki noma ezisebenzayo, njengensimbi engagqwali, i-titanium, i-aluminium kanye nengxubevange yayo.

3.Ukusika umoya-mpilo

Isebenzisa i-laser njengomthombo wokushisa futhi isebenzisa igesi esebenzayo njengomoya-mpilo njengomoya wokusika. Ukusebenzisa lolu hlobo lokusika nge-laser, isivinini sokusika sishesha kakhulu kunokusika ngokuhwamuka nokuncibilika. Ukusika umoya-mpilo kuvame ukusetshenziselwa ukusika izinto zensimbi ezi-oxidizable njenge-carbon steel, insimbi ye-titanium kanye nensimbi yokwelapha ukushisa.

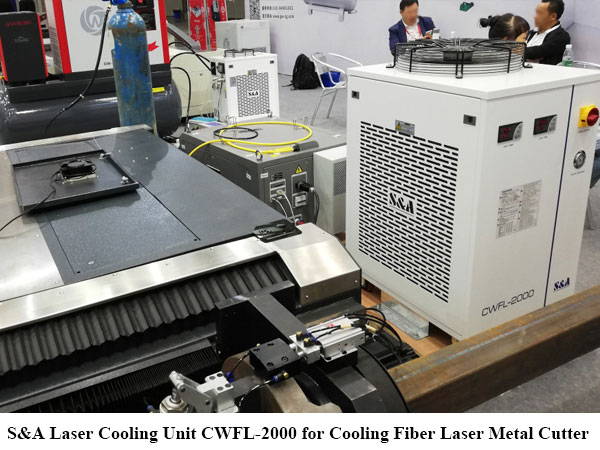

Njengomthombo omkhulu we-laser wensimbi yokusika umshini wokusika, i-fiber laser idlala indima ebalulekile futhi idinga ukuvikelwa okukhethekile. Futhi ukuvikela okuhle kungaba ukupholisa okwanele ngeyunithi yokupholisa nge-laser. S&A Iyunithi yokupholisa i-laser yochungechunge lwe-Teyu CWFL ifaneleka ngokukhethekile ukupholisa i-fiber laser futhi ibonakala ngesistimu yokulawula ukushisa okumbaxambili.

Thola ulwazi olwengeziwe mayelana S&A I-Teyu CWFL yochungechunge lwe-laser chiller yamanzi ku-https://www.chillermanual.net/fiber-laser-chillers_c2