Closed-Loop Water Chillers Improve Waterjet System Performance and Reliability

Waterjet machines utilize high-pressure water streams combined with abrasive materials to cut through a wide range of substrates, such as metal and stone. This process generates significant heat, particularly from the high-pressure pumps, which, if unmanaged, can lead to overheating and decreased performance. To ensure consistent and optimal operation, an effective cooling system, like a closed-loop water chiller, is essential for regulating temperature and preventing downtime.

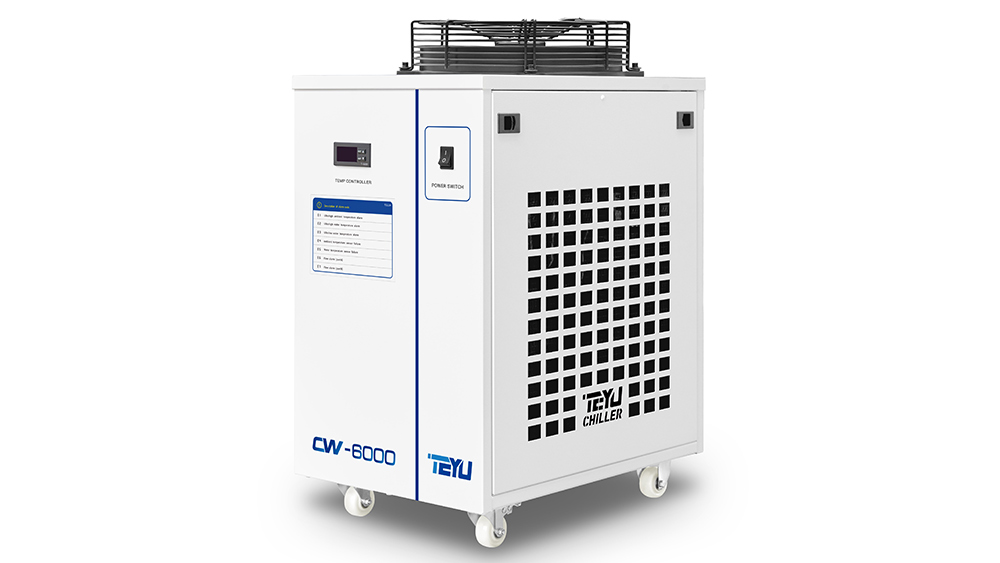

TEYU’s CW-series closed-loop water chillers offer the perfect cooling solution for waterjet systems. With their large cooling capacity, precise temperature control, energy efficiency, and compact design, these chillers effectively prevent overheating and ensure smooth, uninterrupted operation. Whether you're cutting metal, glass, or other materials, our high-performance chillers will protect your equipment and boost productivity. Contact us today to explore our tailored cooling solutions for your waterjet applications!

TEYU CW series industrial chillers are known for their high efficiency and stability and are ideal for cooling a variety of industrial and laser applications, including helium compressors. They feature a compact design that maximizes cooling performance while saving space. With a temperature control accuracy of ±0.5°C/1°C and a cooling capacity of up to 42kW, these industrial chillers meet the cooling needs of small, medium, and large helium compressors. They use eco-friendly refrigerants, offer various power specifications, and come equipped with multiple safety alarms. Certified by CE and other international standards, they also include a 2-year warranty.

Model: CW-5000 ~ CW-8000

Brand: TEYU

Maker: TEYU S&A Chiller

Cooling capacity: 750W ~ 42kW

Warranty: 2 years

Standard: CE, REACH and RoHS

TEYU CW series closed-loop water chillers include CW-5000, CW-5200, CW-6000, CW-6100, CW-6200, CW-6260, CW-6300, CW-6500, CW-7500, CW-7800, CW-7900, CW-8000. The product parameters here only list the chiller models that are more widely used in waterjet cutting machines. If you want to know the complete version of our closed-loop water chillers, don't hesitate to get in touch with us via sales@teyuchiller.com.

| Model | CW-6000 | CW-6100 | CW-6200 | CW-6260 | CW-6300 | CW-6500 |

| Voltage | AC 1P 110V~240V | AC 1P 220-240V | AC 1P 220-240V | AC 1P 220-240V | AC 3P 380V | AC 3P 380V |

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz |

| Current | 0.4~14.4A | 0.4~8.8A | 0.4~10.1A | 3.4~21.6A | 1.2~29.3A | 1.4~16.6A |

| Max. power consumption | 0.96~1.51kW | 1.34~1.84kW | 1.63~1.97kW | 3.56~3.84kW | 5.24~5.52kW | 7.55~8.25kW |

| Compressor power | 0.79~0.94kW | 1.12~1.29kW | 1.41~1.7kW | 2.72~2.76kW | 2.64~2.71kW | 4.6~5.12kW |

| 1.06~1.26HP | 1.5~1.73HP | 1.89~2.27HP | 3.64~3.76HP | 3.59~4.28HP | 6.16~6.86HP | |

| Nominal cooling capacity | 10713Btu/h | 13648Btu/h | 17401Btu/h | 30708Btu/h | 30708Btu/h | 51880Btu/h |

| 3.14kW | 4kW | 5.1kW | 9kW | 9kW | 15kW | |

| 2699Kcal/h | 3439Kcal/h | 4384Kcal/h | 7738Kcal/h | 7738Kcal/h | 12897Kcal/h | |

| Pump power | 0.05~0.6kW | 0.09~0.37kW | 0.09~0.37kW | 0.55~0.75kW | 0.55~0.75kW | 0.55~1kW |

| Max. pump pressure | 1.2~4bar | 2.5~2.7bar | 2.5~2.7bar | 4.4~5.3bar | 4.4~5.3bar | 4.4~5.9bar |

| Max. pump flow | 13~75L/min | 15~75L/min | 15~75L/min | 75L/min | 75L/min | 75~130L/min |

| Refrigerant | R-410a | R-410a | R-410a | R-410a | R-410a | R-410a |

| Precision | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±1℃ | ±1℃ |

| Reducer | Capillary | Capillary | Capillary | Capillary | Capillary | Capillary |

| Tank capacity | 12L | 22L | 22L | 22L | 40L | 40L |

| Inlet and outlet | Rp1/2" | Rp1/2" | Rp1/2" | Rp1/2" | Rp1" | Rp1" |

| N.W. | 35~43Kg | 53~55Kg | 56~59Kg | 81Kg | 113~123Kg | 124Kg |

| G.W. | 44~52Kg | 64~66Kg | 67~70Kg | 98Kg | 140~150Kg | 146Kg |

| Dimension | 59X38X74cm (L X W X H) | 67X47X89cm (L X W X H) | 67X47X89cm (L X W X H) | 77X55X103cm (L X W X H) | 83X65X117cm (L X W X H) | 83X65X117cm (L X W X H) |

| Package dimension | 66X48X92cm (L X W X H) | 73X57X105cm (L X W X H) | 73X57X105cm (L X W X H) | 78X65X117cm (L X W X H) | 95X77X135cm (L X W X H) | 95X77X135cm (L X W X H) |

Note: The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Cooling Capacity: 750W ~ 42kW

* Active cooling

* Temperature stability: ±0.3°C ~ ±1°C

* Temperature control range: 5°C ~ 35°C

* Refrigerant:R-134a or R-410a

* Compact, portable design and quiet operation

* High efficiency compressor

* Top mounted water fill port

* Integrated alarm functions

* Low maintenance and high reliability

* 50Hz/60Hz dual-frequency compatible available

* Optional dual water inlet & outlet

* Optional Items: Heater, Filter, US standard plug / EN standard plug

Tips: (1)Maintain a distance of more than 1.5m between the chiller's air outlet (fan) and obstacles and a distance of more than 1m between the chiller's air inlet (filter gauze) and obstacles to facilitate heat dissipation. (2)Regularly use an air gun to clean the dust on the industrial chiller's filter gauze and condenser surface. (3)Replace the cooling water every 3 months and clean pipeline impurities or residues to keep the water circulation system unobstructed.

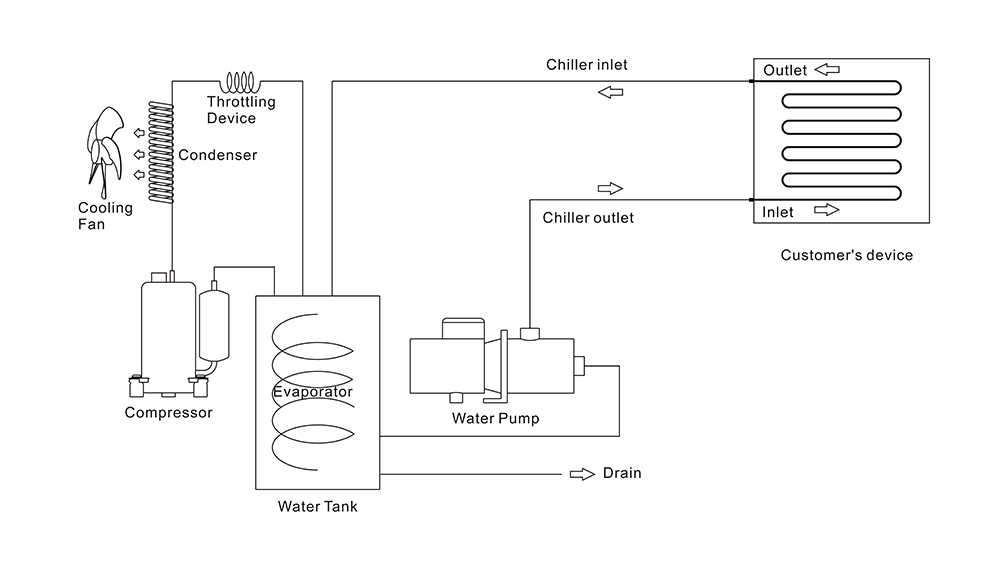

An effective cooling solution for waterjet systems is the oil-water heat exchange closed circuit combined with a water chiller. This method involves transferring heat from the waterjet's oil-based system to a separate water loop. A water chiller then removes heat from the water before it's recirculated. This closed-loop design prevents contamination and ensures optimal cooling efficiency.

All our industrial chillers comply with REACH, RoHS, and CE certifications, ensuring their suitability for global markets. Select models also carry the UL mark, further expanding their reach into North American applications.

Renowned for their compact design, lightweight portability, intelligent control systems, and comprehensive alarm protection, TEYU CW-series water chillers are ideally suited for cooling various industrial and laser applications that require precise cooling, e.g. laser equipment, machine tools, 3d printers, waterjet cutting machines, furnaces, vacuum ovens, vacuum pumps, MRI equipment, analytical equipment, rotary evaporator, gas generators, helium compressor, injection molding machine, etc, providing customer-oriented ideal cooling solutions. Contact us via sales@teyuchiller.com to get your customized cooling solution now!

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.