Heater

Filter

US standard plug / EN standard plug

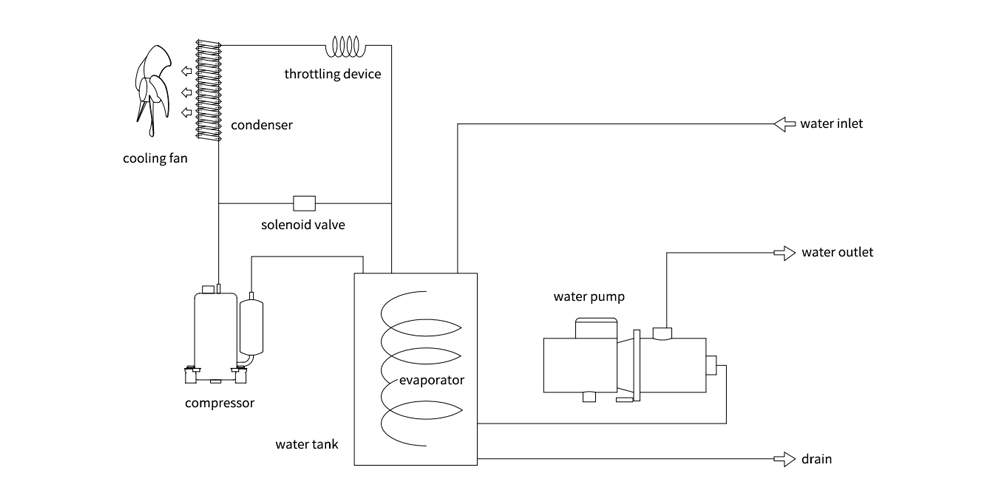

CNC spindle water cooling system CW-6260 is ideally suited to cool 55kW to 80kW spindle. By offering continuous and reliable water flow to the spindle, it can take away the heat from the spindle effectively so that the spindle can always maintain at a suitable temperature. This closed loop chiller works well with environmental refrigerant R-410A. The water filling port is slightly tilted for easy water adding while a water level check is divided into 3 color areas for easy reading. 4 caster wheels mounted at the bottom makes relocation much easier. All these suggest that S&A Chiller really cares and understands what customers need.

Model: CW-6260

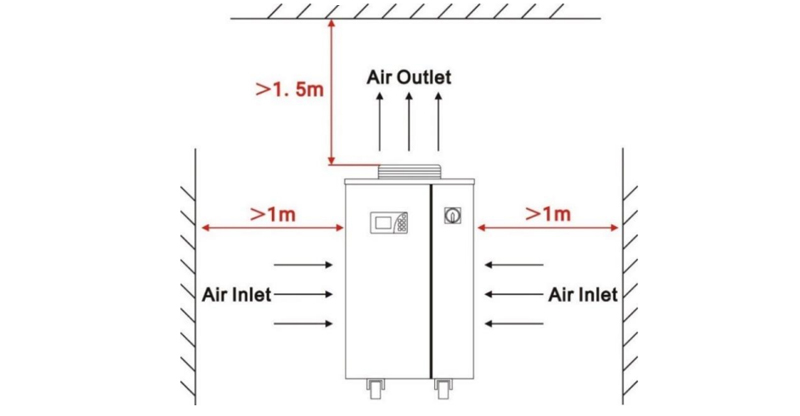

Machine Size: 75 × 55 × 102cm (L × W × H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CW-6260AN | CW-6260BN |

| Voltage | AC 1P 220-240V | AC 1P 220-240V |

| Frequency | 50Hz | 60Hz |

| Current | 3.4~21.6A | 3.9~21.1A |

|

Max. power consumption |

3.56kW | 3.84kW |

|

|

2.76kW | 2.72kW |

| 3.76HP | 3.64HP | |

|

|

30708Btu/h | |

| 9kW | ||

| 7738Kcal/h | ||

| Refrigerant | R-410A/R-32 | |

| Pump power | 0.55kW | 0.75kW |

|

Max. pump pressure |

4.4 bar | 5.3 bar |

|

Max. pump flow |

75L/min | |

| Precision | ±0.5℃ | |

| Reducer | Capillary | |

| Tank capacity | 22L | |

| Inlet and outlet | Rp1/2" | |

| N.W | 81Kg | |

| G.W | 98Kg | |

| Dimension | 75 × 55 × 102cm (L × W × H) | |

| Package dimension | 78 × 65 × 117cm (L × W × H) | |

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Cooling Capacity: 9kW

* Active cooling

* Temperature stability: ±0.5℃

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410A/R-32

* Intelligent temperature controller

* Multiple alarm functions

* Ready for immediate use

* Easy maintenance and mobility

* Visual water level

Heater

Filter

US standard plug / EN standard plug

Intelligent temperature controller

The temperature controller offers high precision temperature control of ±0.5°C and two user-adjustable temperature control modes - constant temperature mode and intelligent control mode.

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.