Heater

Filter

US standard plug / EN standard plug

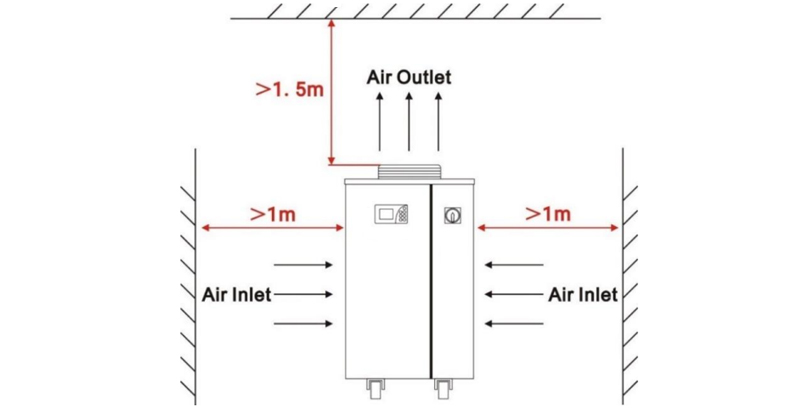

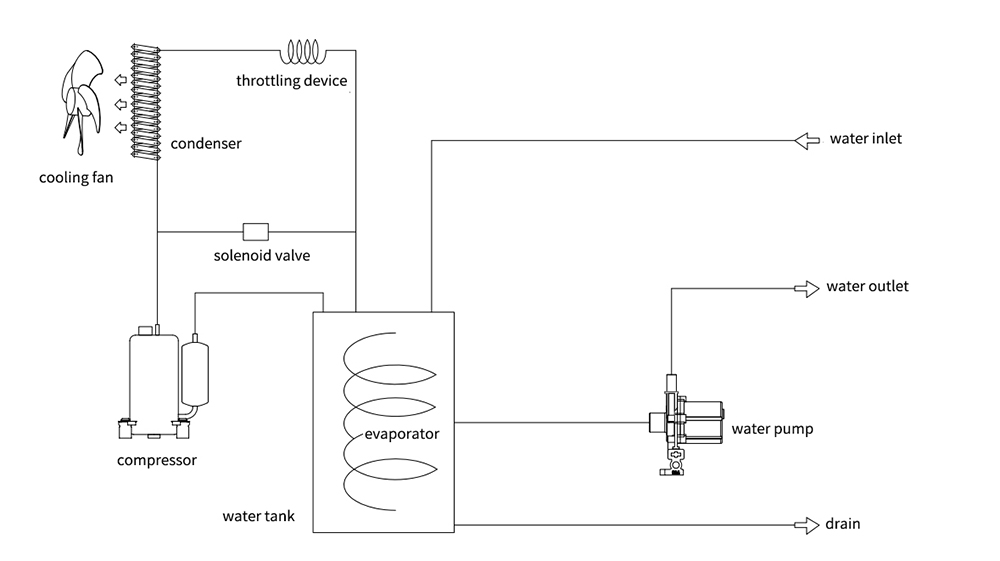

Spindle chiller unit CW-5300 is best suited for 18kW CNC milling spindle in need of proper thermal management. This air cooled water chiller unit uses a high performance water pump to circulate water between the chiller and the spindle. Available in 220V or 110V, recirculating chiller CW-5300 can cool down the stator and bearing outer ring of the spindle effectively and at the same time keep a low noise level. The disassembly of side dust-proof filter for the periodic cleaning operations is easy with fastening system interlocking.

Model: CW-5300

Machine Size: 58 × 39 × 75cm (L × W × H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CW-5300AH | CW-5300BH | CW-5300DH | CW-5300AI | CW-5300BI | CW-5300DI | CW-5300AN | CW-5300BN | CW-5300DN |

| Voltage | AC 1P 220-240V | AC 1P 220-240V | AC 1P 110V | AC 1P 220-240V | AC 1P 220-240V | AC 1P 110V | AC 1P 220-240V | AC 1P 220-240V | AC 1P 110V |

| Frequency | 50Hz | 60Hz | 60Hz | 50Hz | 60Hz | 60Hz | 50Hz | 60Hz | 60Hz |

| Current | 0.5~5.2A | 0.5~4.9A | 0.5~8.9A | 0.4~5.1A | 0.4~4.8A | 0.4~8.8A | 2.3~7A | 2.1~6.5A | 6~14.4A |

|

Max. power consumption |

1.08kW | 1.04kW | 0.96kW | 1.12kW | 1.03kW | 1.0kW | 1.4kW | 1.36kW | 1.51kW |

| Compressor power | 0.94kW | 0.88kW | 0.79kW | 0.94kW | 0.88kW | 0.79kW | 0.88kW | 0.88kW | 0.79kW |

| 1.26HP | 1.18HP | 1.06HP | 1.26HP | 1.18HP | 1.06HP | 1.18HP | 1.18HP | 1.06HP | |

| Nominal cooling capacity | 8188Btu/h | ||||||||

| 2.4kW | |||||||||

| 2063Kcal/h | |||||||||

| Pump power | 0.05kW | 0.09kW | 0.37kW | 0.6kW | |||||

|

Max. pump pressure |

1.2 bar | 2.5 bar | 2.7 bar | 4 bar | |||||

|

Max. pump flow |

13L/min | 15L/min | 75L/min | ||||||

| Refrigerant | R-410A/R-32 | ||||||||

| Precision | ±0.5℃ | ||||||||

| Reducer | Capillary | ||||||||

| Tank capacity | 12L | ||||||||

| Inlet and outlet | Rp1/2" | ||||||||

| N.W. | 34kg | 37kg | 35kg | 39kg | 35kg | 41kg | 44kg | 43kg | |

| G.W. | 43kg | 46kg | 44kg | 48kg | 44kg | 50kg | 53kg | 52kg | |

| Dimension | 58 × 39 × 75cm (L × W × H) | ||||||||

| Package dimension | 66 × 48 × 92cm (L × W × H) | ||||||||

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Cooling Capacity: 2400W

* Active cooling

* Temperature stability: ±0.5°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410A/R-32

* Intelligent temperature controller

* Integrated alarm functions

* Back mounted water fill port and easy-to-read water level indicator

* Low maintenance and high reliability

* Simple setup and operation

Heater

Filter

US standard plug / EN standard plug

Intelligent temperature controller

The temperature controller offers high precision temperature control of ±0.5°C and two user-adjustable temperature control modes - constant temperature mode and intelligent control mode.

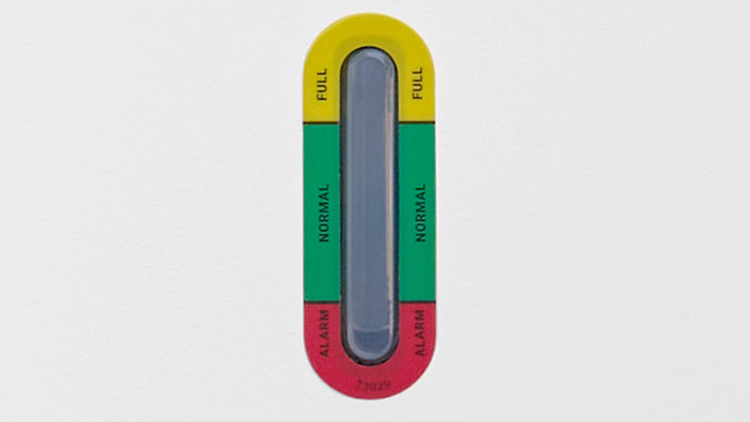

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.