Hydraulic press brakes can overheat during continuous or high-load operation, especially in warm environments. An industrial chiller helps maintain stable oil temperatures, ensuring consistent bending accuracy, improved equipment reliability, and extended service life. It's a vital upgrade for high-performance sheet metal processing.

Does Your Press Brake Need an Industrial Chiller?

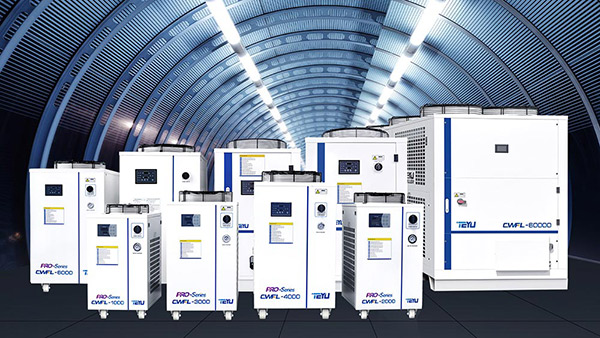

Hydraulic press brakes generate substantial heat during operation, mainly from the hydraulic system. While many machines include built-in air-cooled radiators, these are not always sufficient under demanding conditions. In high-intensity or high-temperature environments, an industrial chiller becomes essential to ensure consistent performance, machining accuracy, and long-term equipment reliability.

When Does a Press Brake Need a Chiller?

High-Intensity, Continuous Operation: Long hours of processing thick or high-strength materials like stainless steel can cause excessive heat buildup.

High Ambient Temperatures: Poorly ventilated workshops or hot summer months can significantly reduce the efficiency of internal air cooling.

Precision and Stability Requirements: Rising oil temperatures reduce viscosity, destabilizing system pressure and increasing internal leakage, directly impacting bending angle and dimensional accuracy. A chiller keeps hydraulic oil at an optimal, stable temperature.

Inadequate Built-in Cooling: If the oil temperature regularly exceeds 55°C or even 60°C, or if precision and pressure fluctuations occur after long operation, an external chiller is likely necessary.

Why an Industrial Chiller Adds Value

Consistent Oil Temperature: Maintains bending accuracy and repeatability across production runs.

Enhanced Equipment Reliability: Prevents overheating-related failures, such as damaged hydraulic components, degraded seals, and oil oxidation, minimizing downtime.

Extended Equipment Lifespan: Protects the hydraulic system's core components from thermal stress and wear.

Higher Productivity: Enables stable, full-load operation over extended periods without compromising performance.

While small, intermittently used press brakes may function well with internal cooling, mid-to-large hydraulic press brakes used in continuous, high-load applications or high-temperature settings will benefit greatly from an industrial chiller. It's not just a helpful add-on—it's a smart investment in performance, longevity, and production efficiency. Always monitor your machine's oil temperature and operational behavior to make an informed decision.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.