Laser chiller is composed of a compressor, a condenser, a throttling device (expansion valve or capillary tube), an evaporator and a water pump. After entering the equipment that needs to be cooled, the cooling water takes away the heat, heats up, returns to the laser chiller, and then cools it again and sends it back to the equipment.

The working principle of laser chiller

During the long-term operation of fiber laser, ultraviolet laser, YAG laser, CO2 laser, ultrafast laser and other laser equipment, the laser generator will continue to generate high temperature, and if the temperature is too high, the normal operation of the laser generator will be affected, so a laser chiller is required for water circulation cooling to control the temperature. Laser chiller is industrial cooling equipment designed and manufactured for laser cutting, laser welding, laser marking, laser engraving and other laser processing equipment, which can provide a temperature-stable cooling medium for the above application scenarios.

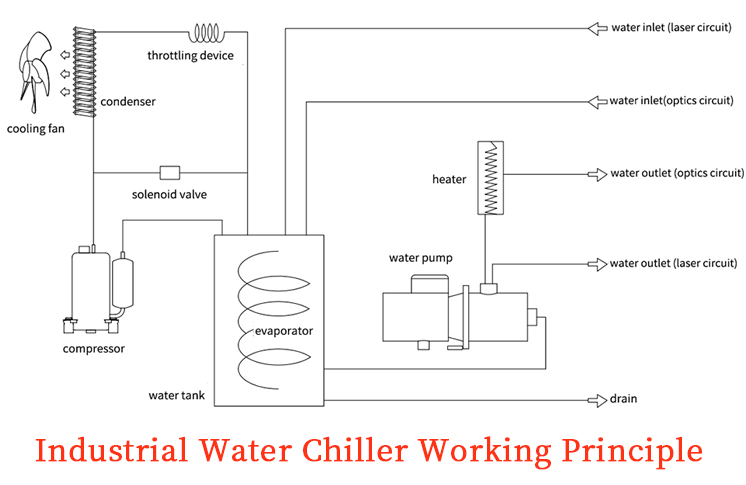

Laser chiller is composed of a compressor, a condenser, a throttling device (expansion valve or capillary tube), an evaporator and a water pump. After entering the equipment that needs to be cooled, the cooling water takes away the heat, heats up, returns to the laser chiller, and then cools it again and sends it back to the equipment. In the laser chiller refrigeration system, the refrigerant in the evaporator coil is vaporized into steam by absorbing the heat of the return water. The compressor continuously extracts the generated steam from the evaporator and compresses it. The compressed high-temperature and high-pressure steam are sent to the condenser, and then the heat is released (the heat is taken away by the fan) and condensed into a high-pressure liquid. After passing through the throttling device to reduce pressure, it enters the evaporator, vaporizes again, and absorbs the heat of the water. In this repeating cycle, the chiller user can pass the thermostat to set or observe the water temperature working state.

Founded in 2002, S&A chiller has 20 years of experience in industrial water chiller refrigeration. S&A chiller can meet the cooling needs of various laser equipment in the full power range, temperature control accuracies of ±0.1℃, ±0.2℃, ± 0.3°C, ±0.5°C and ±1°C are available for selection, which can precisely control the fluctuation of water temperature.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.