Industrial chillers are essential cooling equipment in many industrial applications and play a crucial role in ensuring smooth production lines. In hot environments, it may activate various self-protection functions, such as the E1 ultrahigh room temperature alarm, to ensure safe production. Do you know how to solve this chiller alarm fault? Following this guide will help you solve the E1 alarm fault in your TEYU S&A industrial chiller.

How to Solve the E1 Ultrahigh Room Temperature Alarm Fault of Industrial Chillers?

With summer heat in full swing, industrial chillers—vital cooling equipment in many industrial applications—play a crucial role in ensuring smooth production lines. In hot environments, industrial chillers may activate various self-protection functions, such as the E1 ultrahigh room temperature alarm, to ensure safe production. This guide will help you troubleshoot the E1 alarm in TEYU S&A's industrial chillers:

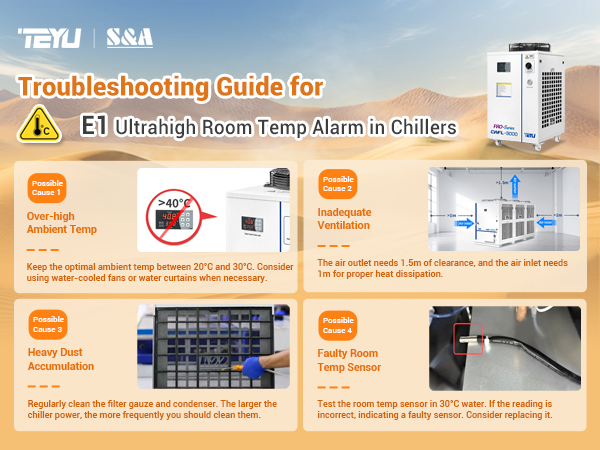

Possible Cause 1: Over-high Ambient Temperature

Press the “▶” button on the controller to enter the status display menu and check the temperature shown by t1. If it's close to 40°C, the ambient temperature is too high. It's recommended to maintain the room temperature between 20-30°C to ensure the industrial chiller operates normally.

If the high workshop temperature affects the industrial chiller, consider using physical cooling methods like water-cooled fans or water curtains to reduce the temperature.

Possible Cause 2: Inadequate Ventilation Around the Industrial Chiller

Check that there is sufficient space around the air inlet and outlet of the industrial chiller. The air outlet should be at least 1.5 meters away from any obstacles, and the air inlet should be at least 1 meter away, ensuring optimal heat dissipation.

Possible Cause 3: Heavy Dust Accumulation Inside the Industrial Chiller

In summer, industrial chillers are used more frequently, causing dust to easily accumulate on filter gauzes and condensers. Regularly clean them and use an air gun to blow off dust from the condenser fins. This will effectively improve the industrial chiller's heat-dissipating efficiency. (The larger the industrial chiller power, the more frequently you should clean.)

Possible Cause 4: Faulty Room Temperature Sensor

Test the room temperature sensor by placing it in water with a known temperature (suggested 30°C) and check if the displayed temperature matches the actual temperature. If there's a discrepancy, the sensor is faulty (a faulty room temperature sensor may trigger the E6 error code). In this case, the sensor should be replaced to ensure the industrial chiller can accurately detect the room temperature and adjust accordingly.

If you still have questions about maintenance or troubleshooting TEYU S&A's industrial chillers, please click Chiller Troubleshooting, or contact our after-sales team at service@teyuchiller.com.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.