Heater

Filter

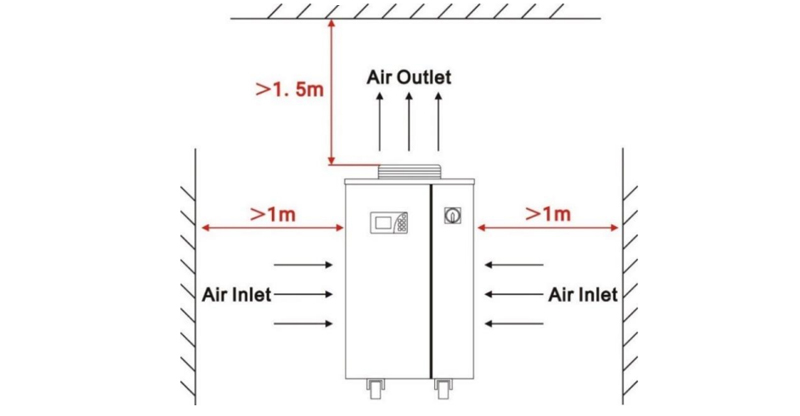

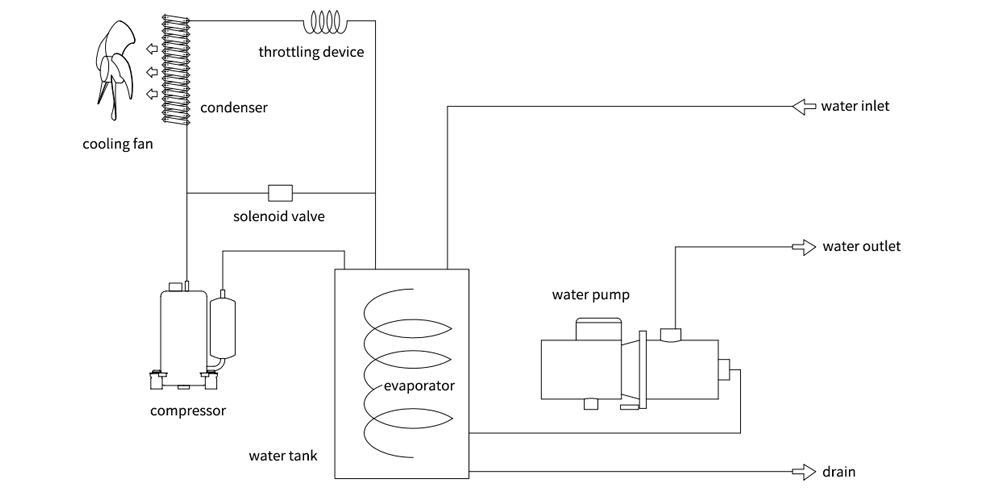

TEYU industrial chiller CW-6500 is preferred over the air or oil cooling system when you have to run your 80kW to 100kW spindle for a long period. When the spindle operates, it tends to generate heat and CW-6500 chiller is an effective and economic way to cool your spindle using water circulation. With up to 15kW large cooling capacity, industrial chiller CW6500 can provide consistent cooling while at the same time offering a high degree of energy efficiency. Refrigerant used is R-410A which is environment friendly.

Water chiller CW-6500 combines durability and easy maintenance. The disassembly of the side dust-proof filter for periodic cleaning operations is easy with the fastening system interlocking. All components are mounted and wired in a proper manner to guarantee the robust running of the chiller unit. RS-485 Modbus function makes it easy to connect with cnc machining system. Optional power voltage of 380V.

Model: CW-6500

Machine Size: 85 × 66 × 119cm (L × W × H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CW-6500ENTY | CW-6500FNTY |

| Voltage | AC 3P 380V | AC 3P 380V |

| Frequency | 50Hz | 60Hz |

| Current | 1.4~16.6A | 2.1~16.5A |

|

Max. power consumption |

7.5kW | 8.25kW |

|

|

4.6kW | 5.12kW |

| 6.26HP | 6.86HP | |

|

|

51880Btu/h | |

| 15kW | ||

| 12897Kcal/h | ||

| Pump power | 0.55kW | 1kW |

|

Max. pump pressure |

4.4 bar | 5.9 bar |

|

Max. pump flow |

75L/min | 130L/min |

| Refrigerant | R-410A/R-32 | |

| Precision | ±1℃ | |

| Reducer | Capillary | |

| Tank capacity | 40L | |

| Inlet and outlet | Rp1" | |

| N.W | 124kg | 135kg |

| G.W | 146kg | 154kg |

| Dimension | 85 × 66 × 119cm (L × W × H) | |

| Package dimension | 95 × 77 × 135cm (L × W × H) | |

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Cooling Capacity: 15000W

* Active cooling

* Temperature stability: ±1°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410A/R-32

* Intelligent temperature controller

* Multiple alarm functions

* Ready for immediate use

* Easy maintenance and mobility

* RS-485 Modbus communication function

* Available in 380V

Intelligent temperature controller

The temperature controller offers high precision temperature control of ±1°C and two user-adjustable temperature control modes - constant temperature mode and intelligent control mode.

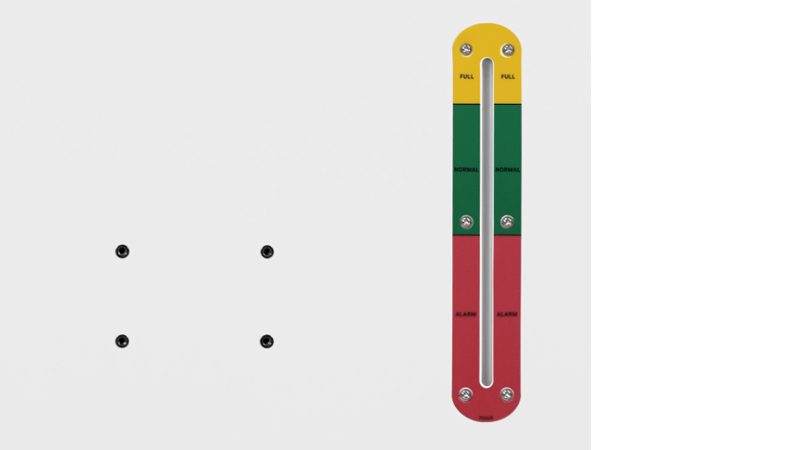

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.