![Codsiyada ballaaran ee gooyayaasha laysarka waxay soo jeedinayaan fursado badan oo loogu talagalay warshadaha wax soo saarka 1]()

Maalmahan, goyayaasha laser-ka ayaa haysta codsiyo ballaaran oo ballaaran oo si tartiib tartiib ah u beddelaya gooyaha plasma, mashiinka goynta waterjet, mashiinka goynta ololka iyo CNC feerka sababtoo ah waxtarka sare ee waxtarka & saxnaanta, tayada sare ee goynta iyo awoodda lagu sameeyo goynta 3D.

Marka loo eego koronto-dhaliyeyaasha laser-ka ee kala duwan, gooyayaasha laser-ka ee hadda jira ee suuqa ayaa asal ahaan loo kala saari karaa gooyaha laser CO2, gooyaha laser YAG iyo gooyaha laser fiber.

Marka la barbardhigo CO2 laser iyo laser YAG, laser fiber ayaa aad uga faa'iido badan sababtoo ah iftiinka tayada sare leh, awoodda wax soo saarka xasilloon iyo dayactir fudud.

Maaddaama bir badan iyo in ka badan loo isticmaalo nolosha iyo codsiga warshadaha, codsiga fiilaha laser fiber-ka ayaa noqonaya mid ballaaran oo ballaaran. Si kastaba ha ahaatee haddii ay tahay farsamaynta birta, hawada hawada, qalabka elektaroonigga ah, qalabka guriga, baabuur, qaybo sax ah ama alaab hadiyad ah ama qalabka jikada ee nolol maalmeedkeena, farsamada goynta laser ayaa badanaa lagu dabaqaa. Wax dhib ah maleh waa bir aan kala go 'lahayn, birta kaarboonka, aluminium, birta ama noocyada kale ee biraha, gooyaha laser wuxuu had iyo jeer u dhamayn karaa shaqada goynta si hufan.

Laysarka Fiber-ka ayaa ah wax-qabad heersare ah oo goynta laser wakhtiga la joogo noloshiisuna waxay noqon kartaa tobanaan kun oo saacadood. Guuldarrooyinka ay sababto lafteedu waa naadir ilaa ay tahay arrin bini'aadmi mooyaane. Xitaa shaqeynta wakhti dheer, laser fiber ma soo saari doono gariir ama saameyn xun oo kale. Marka la barbardhigo CO2 laser kaas oo muraayada ama resonator u baahan yahay dayactir joogto ah, laser fiber ma sameeyo mid ka mid ah kuwaas, si ay u badbaadin karto kharashka dayactirka weyn.

Mashiinka goynta laser Fiber wuxuu la qabsan karaa baahida isbeddelka ee wax soo saarka. Qaybta shaqadu uma baahna wax silcin dheeraad ah, ka saarista burka iyo habsocodyada kale ee habsocodsiinta. Tani waxay sii badbaadisay kharashkii shaqada iyo kharashka farsamaynta, taas oo wanaajisay waxtarka wax soo saarka ilaa xad. Ka sokow, isticmaalka guud ee isticmaalka tamarta fiber laser cutter waa 3 ilaa 5 jeer ka yar kan CO2 laser cutter, taas oo kordhisa waxtarka tamarta by 80%.

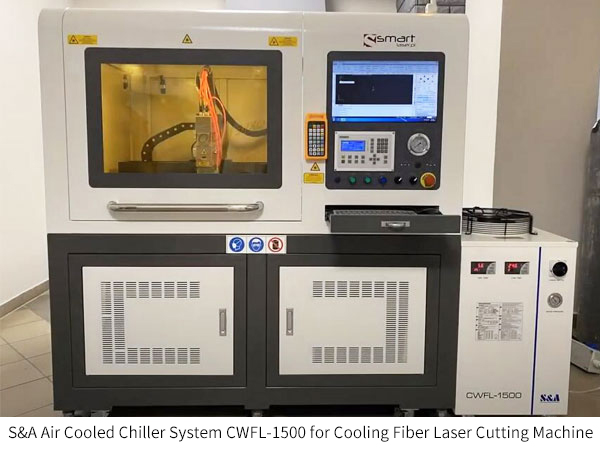

Waa hagaag, si loo ilaaliyo waxqabadka ugu wanaagsan ee orodka fiber laser cutter, laser fiber-ka waa in si fiican loo daryeelo. Si taas loo sameeyo, habka ugu fiican ayaa ah in lagu daro hawo qaboojiye hawo qaboojiye. S&A Nidaamka qaboojiyaha hawada qaboojiyey ee taxanaha Teyu CWFL wuxuu awoodaa inuu ka saaro kulaylka fiber laser cutter isagoo siinaya qaboojin hufan laser fiber iyo madaxa laser siday u kala horreeyaan, iyada oo ay ugu wacan tahay naqshadeeda heerkulbeegga ah. Nidaamka qaboojiyaha ee taxanaha ah ee CWFL wuxuu la socdaa bamka biyaha wax qabad sarreeya si socodka biyaha deggan uu si joogto ah u socdo. Qaar ka mid ah moodooyinka sare xitaa waxay taageeraan nidaamka isgaarsiinta Modbus485 si loo xaqiijiyo xiriirka ka dhexeeya nidaamka laysarka iyo qaboojiyaha.

Ka hel wax badan oo ku saabsan S&A Taxanaha Teyu CWFL hawo qaboojinta nidaamka qaboojiyaha https://www.teyuchiller.com/fiber-laser-chillers_c2

![hawo qaboojiye habka qaboojiyaha hawo qaboojiye habka qaboojiyaha]()