Heater

Filter

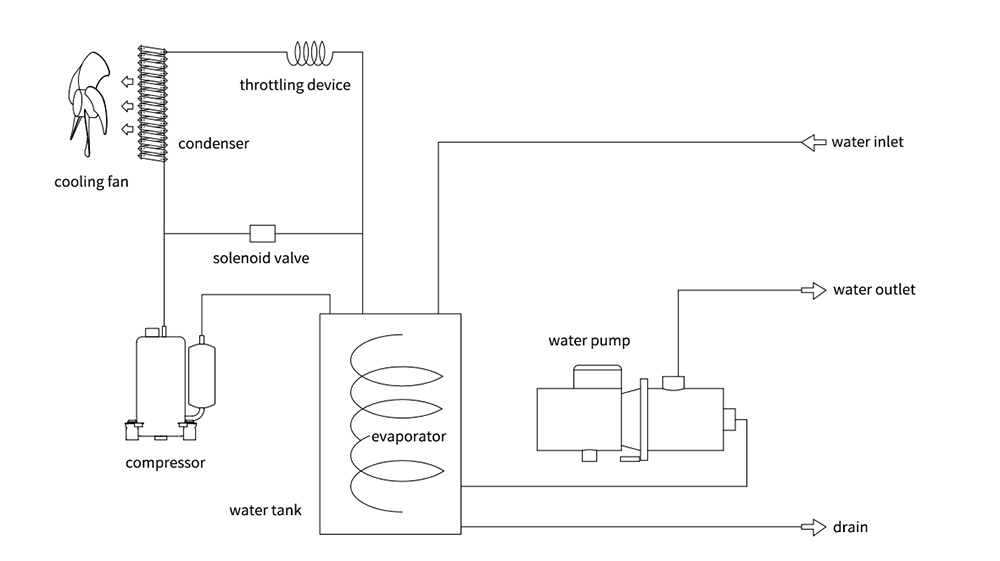

Spindle cooler CW-7800 is an effective method of keeping temperature down to ensure 150kW CNC spindle doesn't overheat. It is designed with the goal of maintaining the machining precision and extending the lifespan of the spindle. This air cooled process chiller uses components that are fully examined and tested to ensure it meets the highest standards of performance and quality. Dust-proof filters are removable for simple maintenance while four caster wheels make relocation quite convenient. Thanks to the visual water level indication, water level and water quality can be monitored clearly from the outside. What makes water chiller outperforms its oil cooling counterpart is that it enables precise temperature control with no risk of oil contamination.

Model: CW-7800

Machine Size: 155 × 80 × 135cm (L × W × H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CW-7800EN | CW-7800FN |

| Voltage | AC 3P 380V | AC 3P 380V |

| Frequency | 50Hz | 60Hz |

| Current | 2.1~23.1A | 2.1~22.7A |

| Max. power consumption | 12.4kW | 14.2kW |

|

|

6.6kW | 8.5kW |

| 8.97HP | 11.39HP | |

|

|

88712Btu/h | |

| 26kW | ||

| 22354Kcal/h | ||

| Refrigerant | R-410A/R-32 | |

| Precision | ±1℃ | |

| Reducer | Capillary | |

| Pump power | 1.1kW | 1kW |

| Tank capacity | 170L | |

| Inlet and outlet | Rp1" | |

| Max. pump pressure | 6.15 bar | 5.9 bar |

| Max. pump flow | 117L/min | 130L/min |

| N.W. | 271kg | 270kg |

| G.W. | 311kg | 310kg |

| Dimension | 155 × 80 × 135cm (L × W × H) | |

| Package dimension | 170 × 93 × 152cm (L × W × H) | |

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Cooling Capacity: 26kW

* Active cooling

* Temperature stability: ±1°C

* Temperature control range: 5°C ~35°C

* Refrigerant: R-410A/R-32

* Intelligent temperature controller

* Multiple alarm functions

* RS-485 Modbus communication function

* High reliability, energy efficiency and durability

* Easy maintenance and mobility

* Available in 380V,415V or 460V

Intelligent temperature controller

The temperature controller offers high precision temperature control of ±1°C and two user-adjustable temperature control modes - constant temperature mode and intelligent control mode.

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

Junction Box

S&A engineers' professional design, easy and stable wiring.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.