Heater

Filter

US standard plug / EN standard plug

Our expertise in high precision cooling technology translates into this small laser process water chiller CWUP-40. This chiller may be simple in design yet it delivers precise cooling featuring ±0.1°C stability with PID control technology and steady flow of chilled water for your ultrafast lasers and UV lasers. Modbus 485 communication function is designed to provide effective communication between chiller and laser system.

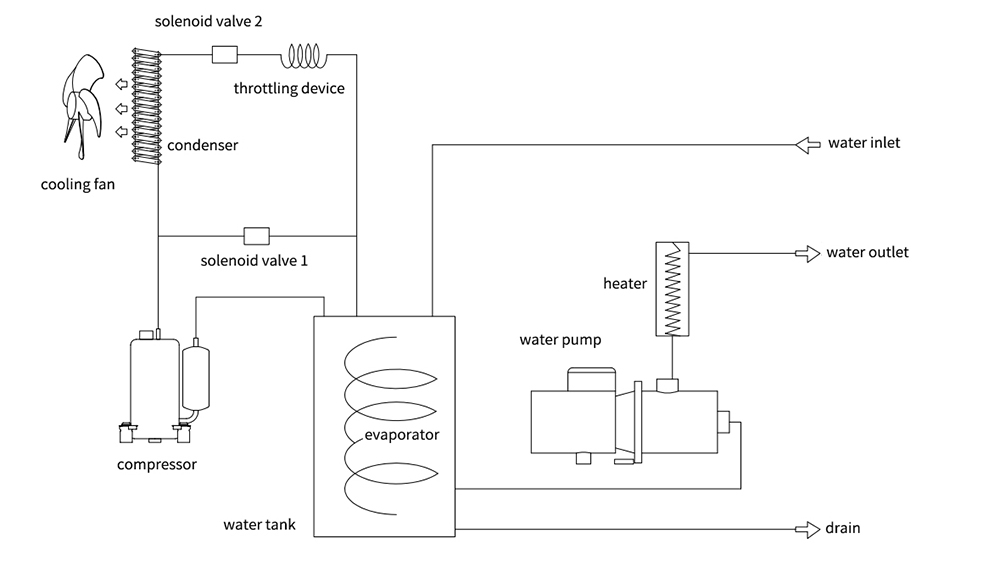

TEYU ultrafast precision laser chiller CWUP-40 is completely self-contained, it combines a high efficiency compressor and a durable fan-cooled condenser and is suitable for purified water, distilled water or deionised water. The water fill port and drain port are mounted on the back together with a thoughtful water level check. Intelligent digital control panel displays the temperature and built-in alarm codes. This chiller is environmentally friendly, energy-saving, high-efficiency, and certified by CE, RoHS and REACH.

Model: CWUP-40

Machine Size: 70 × 47 × 89 cm (L × W × H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CWUP-40ANTY | CWUP-40BNTY | CWUP-40AN5TY | CWUP-40BN5TY |

| Voltage | AC 1P 220-240V | AC 1P 220-240V | AC 1P 220~240V | AC 1P 220~240V |

| Frequency | 50Hz | 60Hz | 50Hz | 60Hz |

| Current | 2.3~11.1A | 2.1~11.4A | 3.4~17.7A | 3.9~18.9A |

|

Max. power consumption |

2.19kW | 2.45kW | 3.63kW | 4.07kW |

|

|

0.92kW | 1.16kW | 1.55kW | 1.76kW |

| 1.25HP | 1.58HP | 2.1HP | 2.4HP | |

|

|

10713Btu/h | 17401Btu/h | ||

| 3.14kW | 5.1kW | |||

| 2699Kcal/h | 4384Kcal/h | |||

| Refrigerant | R-410A /R32 | R-410A | R-410A /R32 | R-410A |

| Precision | ±0.1℃ | |||

| Reducer | Capillary | |||

| Pump power | 0.37kW | 0.55kW | 0.75kW | |

| Tank capacity | 22L | 22L | ||

| Inlet and outlet | Rp1/2” | |||

|

Max. pump pressure |

2.7 bar | 4.4 bar | 5.3 bar | |

| Max. pump flow | 75L/min | |||

| N.W. | 54kg | 56kg | 65kg | 68kg |

| G.W. | 62kg | 64kg | 76kg | 79kg |

| Dimension | 70 × 47 × 89 cm (L × W × H) | |||

| Package dimension | 73 × 57 × 105 cm (L × W × H) | |||

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

Intelligent functions

* Low tank water level detecting

* Low water flow rate detecting

* Over water temperature detecting

* Heating of the coolant water at low ambient temperature

Self-check display

* 12 types of alarm codes

Easy routine maintenance

* Toolless maintenance of dustproof filter screen

* Quick-replaceable optional water filter

Communication function

* Equipped with RS485 Modbus RTU protocol

Heater

Filter

US standard plug / EN standard plug

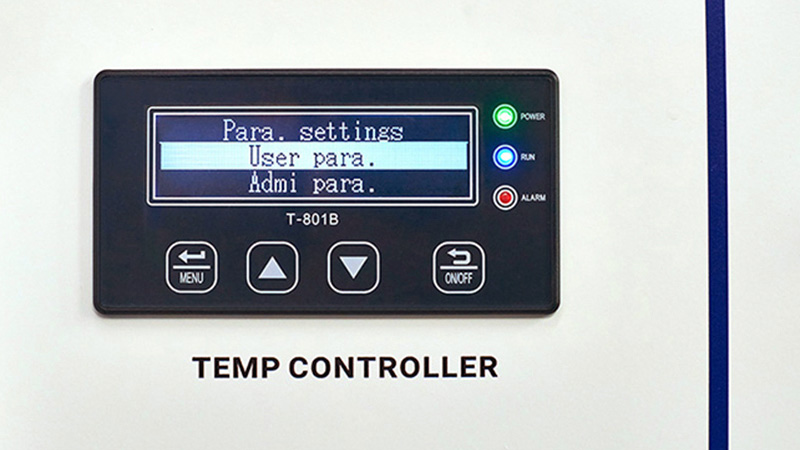

Digital temperature controller

The T-801B temperature controller offers high precision temperature control of ±0.1°C.

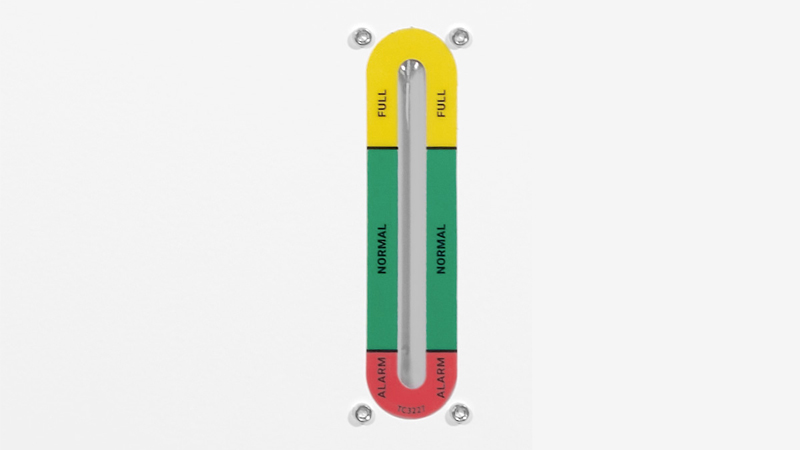

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

Modbus RS485 communication port integrated in the electrical connecting box

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.