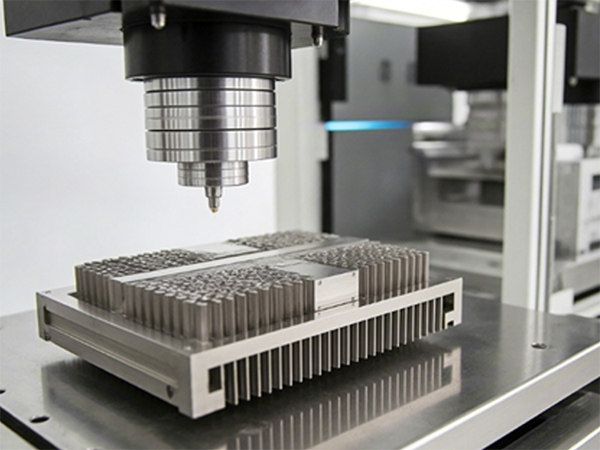

Laser chillers ua lub luag haujlwm tseem ceeb hauv kev txhim kho sintering ceev thiab txo cov txheej txheej hauv hlau 3D luam ntawv los ntawm qhov kub thiab txias, txo qis thermal kev nyuaj siab, thiab ua kom cov hmoov sib xyaw ua ke. Kev txias txias yuav pab tiv thaiv qhov tsis xws luag xws li qhov pores thiab balling, ua rau cov ntawv luam ntau dua thiab muaj zog dua cov hlau.

Yuav ua li cas Laser Chillers txhim kho Sintering ceev thiab txo cov txheej txheej hauv hlau 3D luam ntawv

Nrog rau kev loj hlob ntawm kev siv hlau 3D luam ntawv hauv kev tsim khoom lag luam, qhov kev thov rau cov khoom lag luam zoo tau nce siab. Ntawm cov teeb meem feem ntau yog pom txheej kab thiab txo sintering ceev. Cov no tsis tsuas yog cuam tshuam rau qhov zoo nkauj ntawm lub ntsej muag tab sis kuj tseem tuaj yeem qhia qhov tsis xws luag xws li qhov pores lossis tsis tiav fusion ntawm cov khaubncaws sab nraud povtseg, uas cuam tshuam rau kev ncaj ncees.

Vim li cas Cov Txheej Txheem hnyav qis qis sintering ntom

Cov kab mob hnyav feem ntau qhia tias tsis zoo interlayer fusion lossis microvoids ntawm cov hmoov txheej. Thaum lub sij hawm laser sintering, hlau hmoov yuav tsum yaj thiab solidify uniformly los tsim ib tug ntom, tsis xws luag-dawb qauv. Yog hais tias cov khoom molten tsis tuaj yeem ua tiav qhov sib txawv ntawm cov khoom, cov porosity sab hauv yuav nce, ncaj qha txo cov sintering ntom. Tsis tas li ntawd, kev luam ntawv ceev ceev lossis tsis ruaj tsis khov thermal tuaj yeem ua rau muaj kev ntxhov siab ntau dhau los yog cov neeg kho tshuab kev ntxhov siab, ua rau tsis sib xws, cov khoom tawg, thiab cov txheej txheem tsis muaj zog, tag nrho cov uas ua rau pom cov txheej txheej thiab cuam tshuam qhov zoo.

Yuav ua li cas Laser Chillers Txhim Kho Sintering Ceev

Laser chillers ua lub luag haujlwm tseem ceeb hauv kev ruaj khov ntawm qhov chaw thermal ntawm hlau 3D tshuab luam ntawv. Piv txwv li, TEYU CWFL-3000 fiber ntau laser chiller nta ob lub ntsuas kub tswj Circuit Court, ib qho rau fiber ntau laser qhov chaw thiab lwm yam rau optics. Qhov kev txias txias no ua kom cov cua sov zoo sib xws, tso cai rau cov hmoov hlau kom yaj thiab ua kom muaj zog ntau dua, yog li ua kom sintering ceev.

Los ntawm cov dej txias txias, laser chillers tshem tawm cov cua sov ntau dhau los ntawm cov khoom tseem ceeb xws li lub taub hau thiab hlau substrate. Qhov no minimizes thermal stress, uas yuav pab tiv thaiv cov hmoov xaav thiab warping. Tsis tas li ntawd, kev tswj cov cua txias txhawb kev pom qhov kub thiab txias nyob ib ncig ntawm lub pas dej ua ke, txhawb kev sib zog ua kom khov thiab txo qhov pore tsim.

Laser chillers kuj pab txo cov txiaj ntsig balling, ib qho tshwm sim uas tsis txaus cov hmoov melted tsim kheej kheej hais es tsis txhob sib txuas rau hauv txheej. Los ntawm kev tswj ambient kub thiab txias tus nqi, chillers txhawb kev sib xyaw ua ke ntawm cov hmoov hlau, txo qhov tsis xws luag thiab txhim kho qhov kawg ntawm qhov ceev.

Minimizing Txheej Kab nrog Laser Chillers

Ib puag ncig thermal ruaj khov yog qhov tseem ceeb los txo cov kab hauv cov hlau 3D luam ntawv. Laser chillers pab tswj qhov kub tsis sib xws thoob plaws hauv lub tshuab luam ntawv, tiv thaiv cov cua sov hauv zos thiab tsis sib xws. Qhov no ua rau cov txheej txheem smoother, tsawg dua qhov tsis xws luag, thiab txhim kho qhov tseeb qhov tseeb. Nyob rau hauv luv luv, zoo thermal tswj tsis tau tsuas yog txhim khu kev zoo nkauj ib feem, tab sis kuj xyuas kom meej cov qauv ntawm cov hlau 3D luam tawm Cheebtsam.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.