Laser chillers play a key role in improving sintering density and reducing layer lines in metal 3D printing by stabilizing temperature, minimizing thermal stress, and ensuring uniform powder fusion. Precise cooling helps prevent defects like pores and balling, resulting in higher print quality and stronger metal parts.

How Laser Chillers Improve Sintering Density and Reduce Layer Lines in Metal 3D Printing

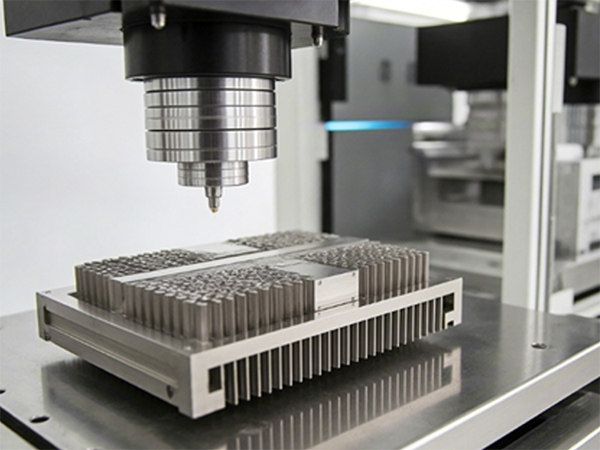

With the growing adoption of metal 3D printing in industrial manufacturing, the demand for high-quality printed components has surged. Among the most concerning issues are visible layer lines and reduced sintering density. These not only affect surface aesthetics but may also signal internal defects such as pores or incomplete fusion between layers, which compromise mechanical integrity.

Why Severe Layer Lines Lower Sintering Density

Severe layer lines often indicate poor interlayer fusion or microvoids between powder layers. During laser sintering, metal powders must melt and solidify uniformly to form a dense, defect-free structure. If the molten material cannot adequately fill the gaps between particles, internal porosity increases, directly reducing sintering density. In addition, rapid print speeds or unstable thermal conditions can introduce excessive thermal or mechanical stress, leading to uneven melting, particle displacement, and weak layer bonding, all of which contribute to visible layering and compromised part quality.

How Laser Chillers Enhance Sintering Density

Laser chillers play a crucial role in stabilizing the thermal environment of metal 3D printers. For example, the TEYU CWFL-3000 fiber laser chiller features dual temperature control circuits, one for the fiber laser source and the other for optics. This precise cooling ensures consistent chamber temperatures, allowing metal powders to melt and solidify more uniformly, thus increasing sintering density.

By circulating chilled water, laser chillers remove excess heat from key components like the print head and metal substrate. This minimizes thermal stress, which helps prevent powder displacement and warping. Additionally, controlled cooling supports optimal temperature gradients around the melt pool, encouraging dense solidification and minimizing pore formation.

Laser chillers also help suppress the balling effect, a phenomenon where insufficiently melted powders form spherical particles instead of bonding into the layer. By controlling ambient temperature and cooling rate, chillers promote uniform fusion of metal powders, reducing this defect and enhancing final part density.

Minimizing Layer Lines with Laser Chillers

A stable thermal environment is key to reducing layer lines in metal 3D printing. Laser chillers help maintain uniform temperatures throughout the print chamber, preventing localized overheating and uneven melting. This results in smoother layer transitions, fewer defects, and improved dimensional accuracy. In short, effective thermal management not only enhances part aesthetics but also ensures the structural integrity of metal 3D printed components.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.