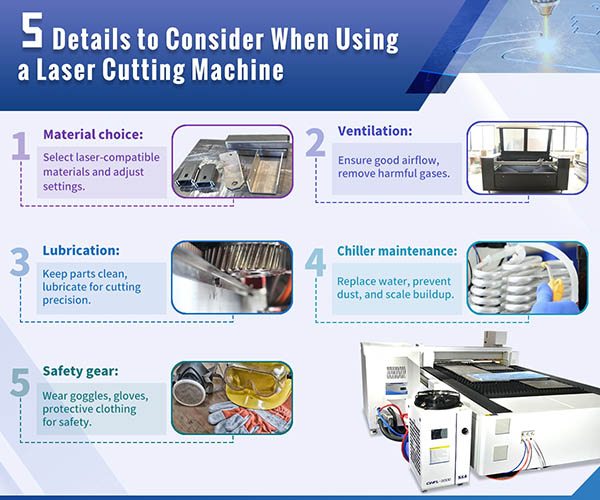

Laser sabon inji ne babban da yawa a masana'antu Laser masana'antu. Tare da muhimmiyar rawar da suke takawa, yana da mahimmanci a ba da fifikon amincin aiki da kiyaye injina. Kuna buƙatar zaɓar kayan da suka dace, tabbatar da isasshen samun iska, tsaftacewa da ƙara lubricants akai-akai, kula da zafin laser akai-akai, da kuma shirya kayan aiki na aminci kafin yanke.

Shin Kun San Tukwici Na Kulawa Don Na'urar Yankan Laser? | TEYU S&A Chiller

Laser sabon inji ne babban da yawa a masana'antu Laser masana'antu. Tare da muhimmiyar rawar da suke takawa, yana da mahimmanci a ba da fifikon amincin aiki da kiyaye injina. Kuma yanzu, mun shiga cikin mafi kyawun cikakkun bayanai waɗanda ke buƙatar kulawa yayin amfani da masu yankan Laser.

1.Material Selection : Tabbatar cewa zabar kayan da ya dace don aikin yankan laser. Abubuwa daban-daban suna amsawa daban-daban ga yankan Laser, don haka yin amfani da kayan da ba daidai ba na iya lalata na'urar Laser ko haifar da yanke ƙarancin inganci. Daidaita saituna yadda ya kamata don guje wa lalacewar abu ko na'ura shima yana da mahimmanci. Idan ba ku da tabbas game da wani abu na musamman, ba a ba ku shawarar yin amfani da abin yanka na Laser akansa ba.

2.Tabbatar da isasshiyar iska: Na'urorin yankan Laser suna samar da ƙura, hayaki, da wari yayin aiki, don haka yana da mahimmanci a sami iskar da ta dace don cire iskar gas mai cutarwa daga wurin aiki, yana tabbatar da amincin ma'aikata. Kula da ingancin iska mai kyau a cikin yanayin aiki kuma yana taimakawa tare da ɓarkewar zafin Laser chiller, hana zafi mai zafi wanda zai iya lalata kayan aikin gani.

3.Lubrication don Smooth Operati akan: Tsabtace akai-akai da ƙura daga duk sassa masu motsi don kiyaye kayan aikin yankan Laser mai tsabta, yana ba da izinin aiki mai sauƙi. Lubrite jagororin da kayan aiki don inganta daidaiton injin da yanke ingancin na'urar. Ya kamata a daidaita tazara don ƙara man mai a kowane lokaci, tare da kusan rabin lokacin bazara idan aka kwatanta da bazara da kaka, kuma a kai a kai ana lura da ingancin mai.

4.Regular Maintenance na Laser Chiller : Daidaitawa na Laser chiller yana da mahimmanci don kiyaye yanayin yanayin aiki mai tsayi, ikon fitarwa na laser, tabbatar da sakamako mai kyau, da kuma tsawaita tsawon rayuwar injin laser. Cire ƙura, canza ruwan zazzagewar zafin laser, da tsaftace duk wani haɓakar sikelin a cikin Laser da bututun bututu suna da mahimmanci don hana ƙurar ƙura (wanda ke haifar da zubar da zafi) da haɓaka sikelin (wanda ke haifar da toshewa), duka biyun na iya daidaita tasirin sanyaya.

5.Prepare Safety Equipmen t: Lokacin aiki da na'urar yankan Laser, koyaushe saka kayan tsaro masu dacewa, gami da tabarau na tsaro, safofin hannu, da tufafi masu kariya. Wadannan abubuwa suna kare idanu, fata, da hannaye yadda ya kamata daga hasken Laser da tarkacen abu.

Muna nan a gare ku lokacin da kuke buƙatar mu.

Da fatan za a cika fom ɗin don tuntuɓar mu, kuma za mu yi farin cikin taimaka muku.