Imishini yokusika i-laser iyinto enkulu ekukhiqizeni i-laser yezimboni. Ngokuhambisana neqhaza labo elibalulekile, kubalulekile ukubeka phambili ukuphepha kokusebenza nokugcinwa komshini. Udinga ukukhetha izinto ezifanele, uqinisekise ukungena komoya owanele, uhlanze futhi wengeze izinto zokugcoba njalo, ugcine i-laser chiller njalo, futhi ulungise imishini yokuphepha ngaphambi kokusika.

Uyawazi Amathiphu Okugcina Umshini Wokusika I-Laser? | I-TEYU S&A Chiller

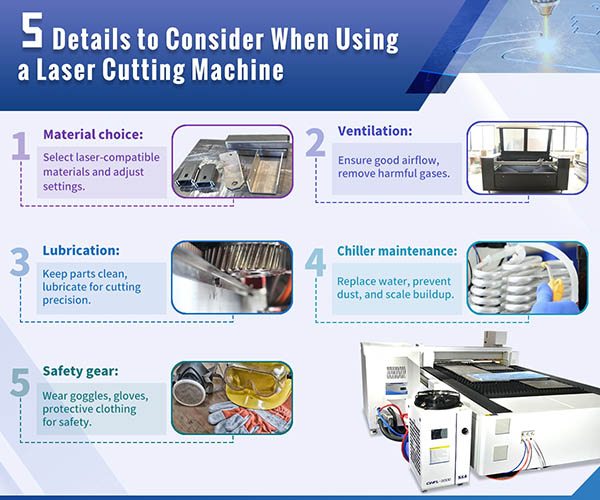

Imishini yokusika i-laser iyinto enkulu ekukhiqizeni i-laser yezimboni. Ngokuhambisana neqhaza labo elibalulekile, kubalulekile ukubeka phambili ukuphepha kokusebenza nokugcinwa komshini. Futhi manje, sihlolisisa imininingwane ecolekileyo efuna ukunakwa uma usebenzisa izisiki ze-laser.

1.Ukukhethwa Kwezinto : Qiniseka ukuthi ukhetha izinto ezifanele zephrojekthi yakho yokusika i-laser. Izinto ezihlukene zisabela ngendlela ehlukile ekusikeni kwe-laser, ngakho-ke ukusebenzisa izinto ezingalungile kungalimaza umshini we-laser noma kubangele ukusikeka kwekhwalithi ephansi. Ukulungisa izilungiselelo ngendlela efanele ukuze ugweme ukulimala kwempahla noma komshini nakho kubalulekile. Uma ungenaso isiqiniseko mayelana nento ethile, akunconywa ukuthi usebenzise i-laser cutter kuyo.

2.Qinisekisa Ukungena komoya Okwanele: Imishini yokusika i-laser ikhiqiza uthuli, intuthu, kanye nephunga ngesikhathi sokusebenza, ngakho-ke kubalulekile ukuba nomoya omuhle ukuze kukhishwe amagesi ayingozi endaweni yokusebenza, ukuqinisekisa ukuphepha kwabasebenzi. Ukugcina ikhwalithi yomoya enhle endaweni yokusebenza futhi kusiza ekulahlekeni kokushisa kwe-laser chiller, ukuvimbela ukushisa okungase konakalise izingxenye ezibonakalayo.

3.I-Lubrication ye-Smooth Operati ivuliwe: Hlanza njalo futhi ukhiphe zonke izingxenye ezihambayo ukuze ugcine imishini yokusika i-laser ihlanzekile, okuvumela ukusebenza kahle. Gcoba iziqondiso namagiya ukuze uthuthukise ukunemba komshini kanye nekhwalithi yokusika. Izikhathi zokwengeza okokugcoba kufanele zilungiswe ngezikhathi ezithile zonyaka, cishe ingxenye yesikhathi sasehlobo uma kuqhathaniswa nentwasahlobo nekwindla, futhi kuqashwe njalo izinga likawoyela.

4.Ukugcinwa Okuvamile Kwe-Laser Chiller : Ukumiswa kwe- laser chiller kubalulekile ekugcineni amazinga okushisa okusebenza azinzile, amandla okukhipha i-laser, ukuqinisekisa imiphumela yokusika yekhwalithi ephezulu, nokwelula isikhathi sokuphila somshini wokusika i-laser. Ukususwa kothuli, ukushintsha amanzi azungezayo e-laser chiller, nokuhlanza noma isiphi isikali ku-laser nepayipi kuyadingeka ukuze kuvinjelwe ukunqwabelana kothuli (okuthinta ukuchithwa kokushisa) nokwakheka kwesikali (okubangela ukuvinjwa), kokubili okungafaka engozini umphumela wokupholisa.

5.Lungiselela Izisetshenziswa Zokuphepha t: Lapho usebenzisa umshini wokusika i-laser, hlala ugqoke izinto ezifanele zokuphepha, okuhlanganisa izibuko zokuphepha, amagilavu, nezingubo zokuzivikela. Lezi zinto zivikela kahle amehlo akho, isikhumba, nezandla zakho emisebeni ye-laser ne-splatter yezinto.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.