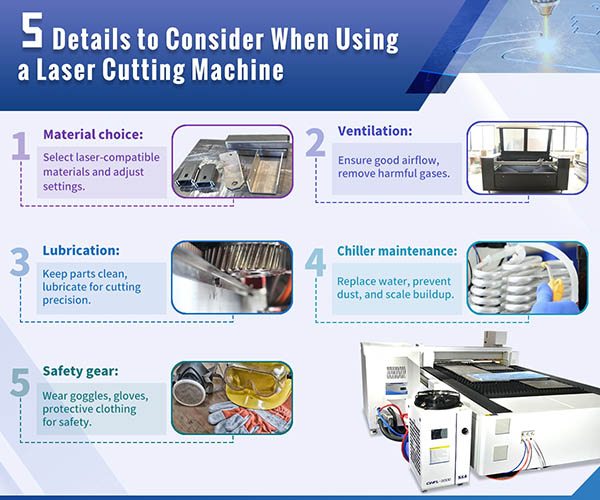

Mashiinnada goynta laser-ka ayaa heshiis weyn ku ah wax soo saarka laser-ka warshadaha. Marka lagu daro doorkooda muhiimka ah, waa muhiim in mudnaanta la siiyo badbaadada hawlgalka iyo dayactirka mishiinka. Waxaad u baahan tahay inaad doorato alaabta saxda ah, hubi hawo ku filan, nadiifi oo ku dar saliidaha si joogto ah, u ilaali qaboojiyaha laysarka si joogto ah, oo u diyaari qalabka badbaadada ka hor intaanad jarin.

Ma taqaanaa Talooyinka Dayactirka Mashiinka Goynta Laser-ka? | TEYU S&A Chiller

Mashiinnada goynta laser-ka ayaa heshiis weyn ku ah wax soo saarka laser-ka warshadaha. Marka lagu daro doorkooda muhiimka ah, waa muhiim in mudnaanta la siiyo badbaadada hawlgalka iyo dayactirka mishiinka. Oo hadda, waxaan u jeexjeexay tafatirka ugu fiican ee u baahan fiiro gaar ah marka la isticmaalayo gooyayaasha laser.

1.Material Selection : Hubi inaad doorato qalabka saxda ah ee mashruuca goynta laysarka. Qalab kala duwan ayaa si kala duwan uga falceliya goynta laysarka, markaa isticmaalka walxaha khaldan waxay dhaawici kartaa mashiinka laysarka ama waxay keeni kartaa goyn tayo hoose leh. U hagaajinta goobaha si habboon si looga fogaado waxyeellada shay ama mashiinka sidoo kale waa muhiim. Haddii aadan hubin shay gaar ah, laguma talinayo inaad isticmaasho qalabka wax lagu gooyo.

2.Hubi hawo ku filan: Mashiinnada goynta laser-ku waxay soo saaraan boodhka, qiiqa, iyo urta inta lagu jiro hawlgalka, markaa waa lagama maarmaan in la helo hawo habboon si looga saaro gaaska waxyeelada leh goobta shaqada, hubinta badbaadada shaqaalaha. Ku-ilaalinta tayada hawada wanaagsan ee jawiga shaqada waxay sidoo kale caawisaa kulaylka qaboojiyaha laysarka, ka hortagga kulaylka oo dhaawici kara qaybaha indhaha.

3.Lubrication for Smooth Operati on: Si joogto ah u nadiifi oo boodhka ka saar dhammaan qaybaha dhaqaaqa si aad u ilaaliso qalabka goynta laysarka nadiif ah, taas oo u oggolaanaysa hawlo fudud. Saliid hagayaasha iyo qalabka si aad u hagaajisid saxnaanta mishiinka oo aad u jarto tayada. Muddada u dhaxeeysa in lagu daro saliidda waa in la hagaajiyaa xilli xilli, iyadoo ku dhawaad kala bar muddada xagaaga la barbar dhigo guga iyo deyrta, oo si joogto ah loola socdo tayada saliidda.

4. Joogtaynta Joogtada ah ee Laser Chiller : Habaynta qaboojiyaha laysarka ayaa muhiim u ah ilaalinta heerkulka hawlgalka ee xasilloon, awoodda wax soo saarka laysarka, hubinta natiijooyinka goynta tayada sare leh, iyo kordhinta cimriga mashiinka goynta laysarka. Boodhka ka saarida, bedelida qaboojiyaha laysarka ee biyaha wareegaya, iyo nadiifinta miisaan kasta oo ku soo ururta laysarka iyo dhuumaha ayaa lagama maarmaan u ah si looga hortago ururinta boodhka (saamaynta kulaylka) iyo kor u qaadista miisaanka (sababta xannibaadda), labaduba waxay wax u dhimi karaan saamaynta qaboojinta.

5. Diyaarso Qalabka Badbaadada t: Markaad shaqaynayso mishiinka goynta laysarka, had iyo jeer xidho qalabka badbaadada ee habboon, oo ay ku jiraan muraayadaha badbaadada, galoofyada, iyo dharka ilaalinta. Waxyaabahani waxay si wax ku ool ah uga ilaaliyaan indhahaaga, maqaarkaaga, iyo gacmahaaga shucaaca laysarka iyo dareeraha alaabta.

Waanu kuu joognaa marka aad noo baahan tahay.

Fadlan buuxi foomka si aad nala soo xiriirto, waana ku faraxsanahay inaan ku caawinno.