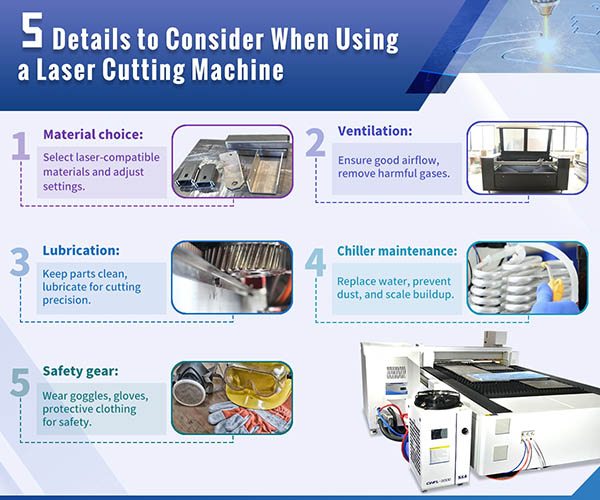

Laser yekucheka michina ihombe muindasitiri Laser kugadzira. Padivi pebasa ravo rakakosha, zvakakosha kukoshesa kuchengetedza kwekushanda uye kugadzirisa kwemuchina. Iwe unofanirwa kusarudza zvinhu zvakanaka, chengetedza mhepo yakakwana, kuchenesa uye kuwedzera mafuta emafuta nguva dzose, chengetedza laser chiller nguva dzose, uye gadzirira midziyo yekuchengetedza usati wacheka.

Unoziva Mazano Ekuchengetedza eLaser Kucheka Machine? | TEYU S&A Chiller

Laser yekucheka michina ihombe muindasitiri Laser kugadzira. Padivi pebasa ravo rakakosha, zvakakosha kukoshesa kuchengetedza kwekushanda uye kugadzirisa kwemuchina. Uye ikozvino, isu tinonyura mune yakakwenenzverwa iyo inoda kutariswa kana uchishandisa laser cutters.

1.Material Selection : Iva nechokwadi chekusarudza zvinhu zvakakodzera zvepurojekiti yako yekucheka laser. Zvinhu zvakasiyana zvinobata zvakasiyana kune laser yekucheka, saka kushandisa zvisirizvo zvinhu zvinogona kukuvadza muchina welaser kana kukonzera kuderedzwa kwemhando yekucheka. Kugadzirisa marongero nenzira kwayo kudzivirira zvinhu kana kukuvara kwemuchina kwakakosha zvakare. Kana usina chokwadi nezvechimwe chinhu, hazvikurudzirwe kushandisa laser cutter pairi.

2.Ensure Yakakwana Ventilation: Laser yekucheka michina inogadzira guruva, utsi, uye hwema panguva yekushanda, saka zvakakosha kuve nemhepo inofefetera kuti ubvise magasi anokuvadza kubva munzvimbo yebasa, kuve nechokwadi chekuchengetedza kwevashandi. Kuchengetedza kunaka kwemhepo munzvimbo yekushanda kunobatsirawo nekupisa kwekupisa kwe laser chiller, kudzivirira kupisa kunogona kukuvadza optical components.

3.Lubrication yeSmooth Operati pa: Nguva dzose yakachena uye guruva kubva kumativi ose anofamba kuti uchengetedze michina yekucheka laser yakachena, ichibvumira kushanda zvakanaka. Zora madhairekitori uye magiya kuti uvandudze kurongeka kwemuchina uye kucheka mhando. Nguva yekuwedzera lubricant inofanirwa kugadziridzwa mwaka, nehafu yenguva yezhizha zvichienzaniswa nechirimo nematsutso, uye kugara uchitarisa kunaka kwemafuta.

4.Regular Maintenance of the Laser Chiller : Kugadziriswa kwe laser chiller kwakakosha pakuchengetedza kugadzikana kwekushisa kwekushanda, simba rekubuda kwelaser, kuve nechokwadi chepamusoro-soro yekucheka migumisiro, uye kuwedzera mararamiro emagetsi ekucheka laser. Kubvisa guruva, kushandura laser chiller's inotenderera mvura, uye kuchenesa chero chiyero chekuvaka mu laser uye pombi zvinodikanwa kudzivirira kuunganidzwa kweguruva (kukanganisa kupisa kupisa) uye chiyero kuvaka (kuchikonzera kuvharika), zvese izvo zvinogona kukanganisa kutonhora.

5.Gadzirira Midziyo Yekuchengetedza t: Paunenge uchishanda laser yekucheka muchina, gara uchipfeka giya rekuchengetedza rakakodzera, kusanganisira magirazi ekuchengetedza, magirovhosi, uye zvipfeko zvinodzivirira. Zvinhu izvi zvinodzivirira maziso ako, ganda, uye maoko kubva kune laser radiation uye zvinhu splatter.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.