Oomatshini bokusika iLaser yinto enkulu kwimveliso ye-laser yeshishini. Ecaleni kwendima yabo engundoqo, kubalulekile ukubeka phambili ukhuseleko lokusebenza kunye nokugcinwa koomatshini. Kufuneka ukhethe izixhobo ezifanelekileyo, uqinisekise ukungena komoya okwaneleyo, ucoce kwaye wongeze i-lubricant rhoqo, ugcine i-laser chiller rhoqo, kwaye ulungiselele izixhobo zokhuseleko ngaphambi kokusika.

Ngaba uyazazi iiNgcebiso zoLondolozo kumatshini wokusika iLaser? | TEYU S&A Chiller

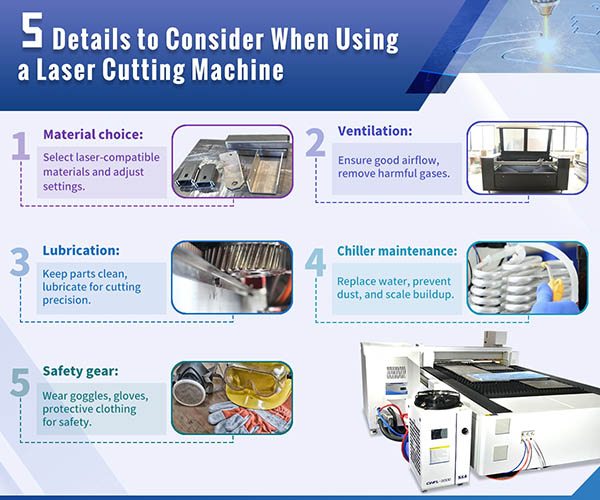

Oomatshini bokusika iLaser yinto enkulu kwimveliso ye-laser yeshishini. Ecaleni kwendima yabo engundoqo, kubalulekile ukubeka phambili ukhuseleko lokusebenza kunye nokugcinwa koomatshini. Kwaye ngoku, siphengulula kwiinkcukacha eziphucukileyo ezifuna ukuhoywa xa usebenzisa izisiki zelaser.

1.Ukukhethwa kwezinto eziphathekayo : Qinisekisa ukuba ukhetha izinto ezifanelekileyo kwiprojekthi yakho yokusika i-laser. Izinto ezahlukeneyo zisabela ngendlela eyahlukileyo kwi-laser cutting, ngoko ke ukusebenzisa izinto ezingalunganga kunokonakalisa umatshini we-laser okanye kubangele ukusika okuphantsi. Ukulungelelanisa iisetingi ngokufanelekileyo ukuphepha ukonakala kwezinto okanye umatshini nako kubalulekile. Ukuba awuqinisekanga malunga nemathiriyeli ethile, akukhuthazwa ukuba usebenzise i-laser cutter kuyo.

2.Ukuqinisekisa ukungena komoya okwaneleyo: Oomatshini bokusika iLaser bavelisa uthuli, umsi, kunye nevumba ngexesha lokusebenza, ngoko ke kubalulekile ukuba kubekho umoya ofanelekileyo wokukhupha iigesi eziyingozi kwindawo yokusebenza, ukuqinisekisa ukhuseleko lwabasebenzi. Ukugcina umgangatho womoya omhle kwindawo yokusebenza kunceda kwakhona ukutshatyalaliswa kobushushu be-laser chiller, ukuthintela ukutshisa okunokonakalisa amacandelo optical.

I-3.I-Lubrication ye-Smooth Operati kwi-: Hlaziya rhoqo kwaye uthuli kuzo zonke iindawo ezihambayo ukugcina izixhobo zokusika i-laser zicocekile, zivumela ukusebenza kakuhle. Gcoba izikhokelo kunye nezixhobo zokuphucula ukuchaneka komatshini kunye nomgangatho wokusika. Amathuba okufaka isithambiso kufuneka ahlengahlengiswe ngamaxesha athile onyaka, malunga nesiqingatha sobude bexesha lasehlotyeni xa kuthelekiswa nentlakohlaza nokwindla, kwaye kubekwe iliso rhoqo umgangatho we-oyile.

I-4.Ukugcinwa rhoqo kwe-Laser Chiller : Ukucwangciswa kwe- laser chiller kubalulekile ekugcineni amaqondo okushisa okuzinzile, amandla okuphuma kwe-laser, ukuqinisekisa iziphumo eziphezulu zokusika, kunye nokwandisa ixesha lokuphila komatshini wokusika i-laser. Ukususwa kothuli, ukutshintsha amanzi ajikelezayo e-laser chiller, kunye nokucoca nasiphi na isikali esakhiweyo kwilaser kunye nombhobho kuyimfuneko ukuthintela ukuqokeleleka kothuli (okuchaphazela ukutshatyalaliswa kobushushu) kunye nokwakhiwa kwesikali (okubangela ukuvaleka), zombini ezinokuthi zibeke esichengeni isiphumo sokupholisa.

5.Lungisa izixhobo zoKhuseleko t: Xa usebenza umatshini wokusika i-laser, soloko unxibe izixhobo ezifanelekileyo zokukhusela, kubandakanywa nezibuko zokukhusela, iiglavu kunye nempahla yokukhusela. Ezi zinto zikhusela amehlo akho, ulusu kunye nezandla zakho kwimitha yelaser kunye ne-splatter yezinto.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.