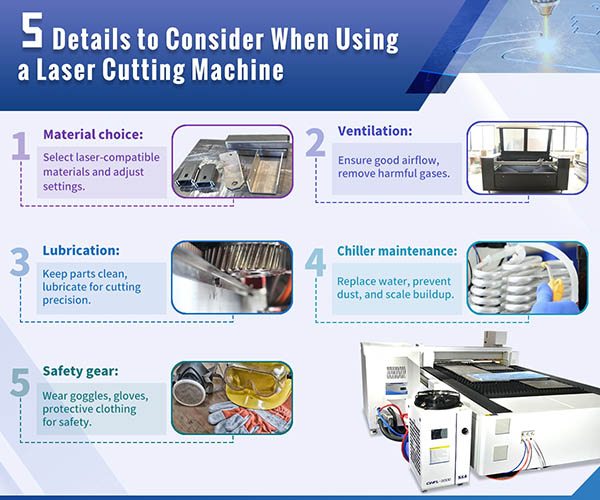

Laser tej tshuab yog ib tug loj deal nyob rau hauv industrial laser manufacturing. Nrog rau lawv lub luag haujlwm tseem ceeb, nws tseem ceeb heev rau kev ua haujlwm tseem ceeb ntawm kev nyab xeeb thiab kev tu lub tshuab. Koj yuav tsum xaiv cov ntaub ntawv tsim nyog, xyuas kom muaj qhov cua txaus, ntxuav thiab ntxiv cov roj nplua nyeem tsis tu ncua, tuav lub laser chiller tsis tu ncua, thiab npaj cov cuab yeej kev nyab xeeb ua ntej txiav.

Koj puas paub cov lus qhia txog kev tu lub tshuab Laser txiav? | TEYU S&A Chiller

Laser tej tshuab yog ib tug loj deal nyob rau hauv industrial laser manufacturing. Nrog rau lawv lub luag haujlwm tseem ceeb, nws tseem ceeb heev rau kev ua haujlwm tseem ceeb ntawm kev nyab xeeb thiab kev tu lub tshuab. Thiab tam sim no, peb delve rau hauv cov ntsiab lus finer uas xav tau kev saib xyuas thaum siv laser cutters.

1.Material Selection : Nco ntsoov xaiv cov ntaub ntawv zoo rau koj qhov project laser txiav. Cov ntaub ntawv sib txawv teb txawv rau laser txiav, yog li siv cov khoom tsis raug tuaj yeem ua rau lub tshuab laser puas lossis ua rau cov txiav tsis zoo. Kev kho cov chaw kom tsim nyog kom tsis txhob muaj cov khoom siv lossis lub tshuab puas tsuaj kuj tseem ceeb heev. Yog tias koj tsis paub meej txog cov khoom siv tshwj xeeb, nws tsis pom zoo kom siv lub laser cutter rau nws.

2.Ua kom muaj cua txaus txaus: Laser txiav tshuab tsim cov plua plav, pa taws, thiab cov ntxhiab tsw thaum lub sijhawm ua haujlwm, yog li nws yog ib qho tseem ceeb uas yuav tsum muaj qhov cua kom zoo kom tshem tawm cov pa phem ntawm qhov chaw ua haujlwm, ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm. Kev tuav cov huab cua zoo nyob rau hauv ib puag ncig kev ua haujlwm kuj pab nrog cov cua kub dissipation ntawm lub laser chiller, tiv thaiv overheating uas tuaj yeem ua rau cov khoom siv kho qhov muag puas.

3.Lubrication rau Smooth Operati rau: Tsis tu ncua ntxuav thiab plua plav tawm txhua qhov chaw txav mus kom cov khoom siv laser txiav huv si, tso cai rau kev ua haujlwm smoother. Lubricate cov lus qhia thiab lub zog los txhim kho lub tshuab precision thiab txiav zoo. Lub ncua sij hawm ntxiv cov roj nplua nyeem yuav tsum tau hloov kho raws caij nyoog, nrog kwv yees li ib nrab ntawm lub caij ntuj sov piv rau lub caij nplooj ntoos hlav thiab lub caij nplooj zeeg, thiab tsis tu ncua saib xyuas cov roj zoo.

4.Regular Maintenance of the Laser Chiller : Kev teeb tsa ntawm lub laser chiller yog qhov tseem ceeb rau kev tswj xyuas qhov kub thiab txias, laser tso zis hluav taws xob, kom ntseeg tau cov txiaj ntsig zoo txiav, thiab txuas lub laser txiav tshuab lub neej ntev. Kev tshem tawm plua plav, hloov lub laser chiller cov dej ntws, thiab ntxuav cov nplais hauv lub laser thiab cov kav dej yog tsim nyog los tiv thaiv cov plua plav paug ( cuam tshuam rau cov cua sov dissipation ) thiab nplai buildup (ua rau txhaws), ob qho tib si tuaj yeem cuam tshuam cov nyhuv txias.

5. Npaj Cov Khoom Siv Kev Nyab Xeeb t: Thaum ua haujlwm ntawm lub tshuab laser txiav, ib txwm hnav cov iav kev nyab xeeb tsim nyog, suav nrog tsom iav, hnab looj tes, thiab khaub ncaws tiv thaiv. Cov khoom no zoo tiv thaiv koj ob lub qhov muag, tawv nqaij, thiab txhais tes los ntawm laser hluav taws xob thiab cov ntaub ntawv splatter.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.