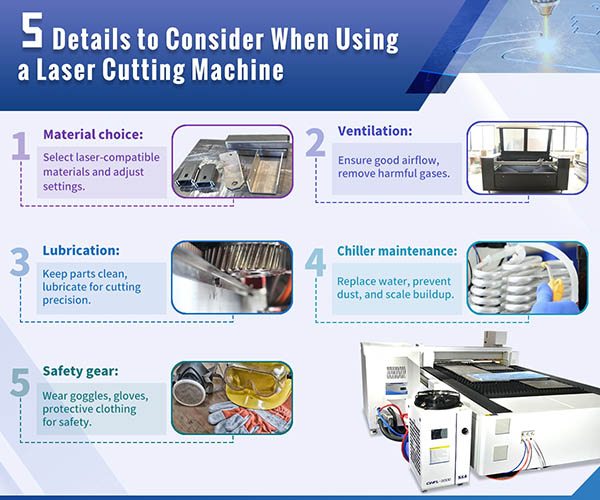

Mechini ea ho itšeha ea laser ke ntho e kholo indastering ea tlhahiso ea laser. Ntle le karolo ea bona ea bohlokoa, ho bohlokoa ho etelletsa pele polokeho ea ts'ebetso le tlhokomelo ea mochini. U hloka ho khetha lisebelisoa tse nepahetseng, ho netefatsa moea o lekaneng, ho hloekisa le ho eketsa mafura khafetsa, ho boloka laser chiller khafetsa, le ho lokisa lisebelisoa tsa polokeho pele u seha.

Na U Tseba Malebela a Tlhokomelo ea Mochini oa ho Seha Laser? | TEYU S&A Chiller

Mechini ea ho itšeha ea laser ke ntho e kholo indastering ea tlhahiso ea laser. Ntle le karolo ea bona ea bohlokoa, ho bohlokoa ho etelletsa pele polokeho ea ts'ebetso le tlhokomelo ea mochini. 'Me joale, re sheba lintlha tse hlakileng haholoanyane tse hlokang tlhokomelo ha u sebelisa li-cutters tsa laser.

Khetho ea 1.Material : Etsa bonnete ba hore u khetha lisebelisoa tse nepahetseng bakeng sa morero oa hau oa ho itšeha ka laser. Lisebelisoa tse fapaneng li itšoara ka tsela e fapaneng le ho itšeha ka laser, kahoo ho sebelisa thepa e fosahetseng ho ka senya mochine oa laser kapa ho fella ka ho fokotsa boleng bo tlaase. Ho lokisa litlhophiso ka nepo ho qoba tšenyo ea thepa kapa mochini le hona ho bohlokoa. Haeba o sa tiisehe ka thepa e itseng, ha e khothalletsoe ho sebelisa laser cutter ho eona.

2. Etsa bonnete ba hore ho na le moea o lekaneng oa moea: Mechini ea ho itšeha ka laser e hlahisa lerōle, mosi le monko nakong ea ts'ebetso, kahoo ho bohlokoa ho ba le moea o nepahetseng ho tlosa likhase tse kotsi sebakeng sa mosebetsi, ho netefatsa polokeho ea basebetsi. Ho boloka boleng bo botle ba moea sebakeng sa ts'ebetso ho boetse ho thusa ka ho senya mocheso oa laser chiller, ho thibela ho chesa ho ka senyang likarolo tsa optical.

3.Lubrication bakeng sa Smooth Operati ka: Ho hloekisa kamehla le lerōle likarolong tsohle tse tsamaeang ho boloka thepa ea ho itšeha ea laser e hloekile, e lumella ho sebetsa hantle. Tlotsa litataiso le likere ho ntlafatsa ho nepahala le boleng ba mochini. Likhao tsa ho eketsa mafura li lokela ho lokisoa ka nako ea selemo, ka nako e ka bang halofo ea nako ea lehlabula ha e bapisoa le selemo le hoetla, 'me khafetsa ho lekola boleng ba oli.

4.Tlhokomelo e Tloaelehileng ea Laser Chiller : Ho hlophisoa ha laser chiller ho bohlokoa bakeng sa ho boloka mocheso o tsitsitseng oa ho sebetsa, matla a tlhahiso ea laser, ho netefatsa liphello tsa boleng bo phahameng ba ho itšeha, le ho lelefatsa bophelo ba mochine oa ho itšeha oa laser. Ho tlosa lerōle, ho fetola metsi a potolohang a laser chiller, le ho hloekisa sekala sefe kapa sefe ka har'a laser le pipeline hoa hlokahala ho thibela ho bokellana ha lerōle (ho amang ho qhalana ha mocheso) le sekala (se bakang ho thibela), tseo ka bobeli li ka senyang phello ea ho pholisa.

5.Lokisetsa Lisebelisoa tsa Tšireletso t: Ha u sebelisa mochine oa ho itšeha ka laser, kamehla u roale lisebelisoa tse loketseng tsa tšireletso, ho kenyelletsa le likhalase tsa tšireletso, liatlana le liaparo tse sireletsang. Lintho tsena li sireletsa mahlo, letlalo le matsoho ka katleho mahlaseling a laser le splatter ea lintho tse bonahalang.

Re mona bakeng sa hau ha o re hloka.

Ka kopo tlatsa foromo ho ikopanya le rona, 'me re tla thabela ho u thusa.