Daidaiton walƙiya na laser na iya zama daidai kamar 0.1mm daga gefen wayar walda zuwa tashar kwarara, wanda ba girgiza, hayaniya, ko ƙura ba yayin aikin walda, yana mai da shi kyakkyawan zaɓi don daidaitattun buƙatun walda na samfuran filastik na likita. Kuma ana buƙatar chiller na Laser don daidaita yanayin zafin Laser ɗin daidai don tabbatar da daidaiton fitowar katako na Laser.

Shin Microfluidics Laser Welding yana buƙatar Laser Chiller?

An haɓaka Microfluidics a cikin 1980s kuma yana nufin fasaha don ingantaccen sarrafawa da sarrafa ƙananan ruwaye, musamman ma tsarin submicron. Fasaha ce ta interdisciplinary da ta ƙunshi sunadarai, kimiyyar ruwa, microelectronics, sabbin kayan aiki, ilmin halitta, da injiniyan halittu. Godiya ga ƙananan ƙararrakinsa, ƙarancin amfani da makamashi, da ƙananan sawun na'ura, microfluidics yana da matukar alƙawarin don aikace-aikace iri-iri a cikin bincike na likita, nazarin kwayoyin halitta, haɗin sinadarai, da kuma kula da muhalli.

Babban nau'i na kwakwalwan kwamfuta na microfluidic yana nufin ainihin haɗin kai na sassan aiki da ke da hannu a fannonin sunadarai da ilmin halitta kamar shirye-shiryen samfurin, amsawa, rabuwa, ganowa, al'adun tantanin halitta, rarrabawa, da lysis zuwa wani yanki na santimita murabba'i da yawa ko ma akan guntu ƙarami. An kafa hanyar sadarwa ta microchannels, kuma ruwa mai iya sarrafawa yana gudana cikin tsarin gaba ɗaya. Microfluidic kwakwalwan kwamfuta suna da fa'idodi da yawa kamar ƙarar haske, ƙarancin samfuri da ƙarar reagent, saurin amsawa, babban aiki daidai gwargwado, da lalacewa a fagen ilimin halitta, sunadarai, magani, da sauransu.

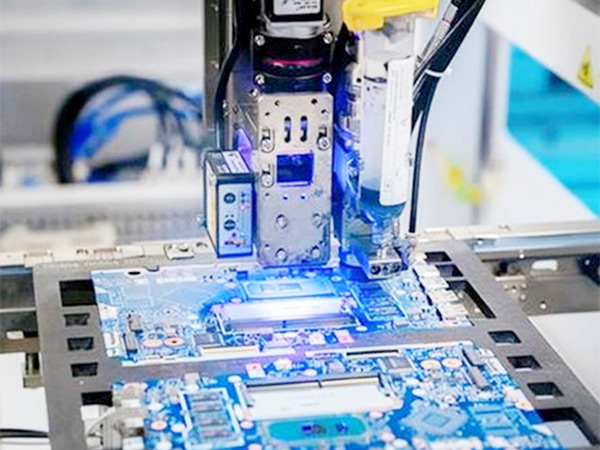

Madaidaicin Laser Welding yana haɓaka Chip Microfluidic

Guntuwar microfluidic ƙaramin guntu ne na filastik wanda ke haɗa matakai da yawa, gami da shirye-shiryen samfurin, halayen ƙwayoyin halitta, da gano sakamako. Koyaya, don canza adadin reagents zuwa microliters ko ma nanoliters ko picoliters, buƙatun fasahar walda suna da girma sosai.

Dabarun walda na gama gari kamar ultrasonic, matsa zafi, da gluing suna da illa. Fasahar Ultrasonic yana da saurin zubewa da ƙura, yayin da fasaha mai zafi mai zafi zai iya lalacewa da ambaliya, yana haifar da ƙarancin samarwa.

Laser walda, a gefe guda, fasaha ce ta walƙiya wacce ba ta hulɗa da juna ba wacce ke amfani da katako mai bakin ciki na Laser don haɗa sassa tare da matsananciyar daidaito da sauri. Wannan hanyar ba ta tasiri tashar kwarara, kuma daidaiton walda zai iya zama daidai kamar 0.1mm daga gefen wayar walda zuwa tashar kwarara. Babu girgiza, hayaniya, ko kura yayin aikin walda. Irin wannan hanyar walda mai tsabta ta sa ya zama kyakkyawan zaɓi don daidaitattun buƙatun walda na samfuran filastik na likita.

Dole ne a Sanya Welding Laser Tare da Laser Chiller

Don sarrafa daidaitaccen guntu na microfluidic, injin walƙiya na Laser yana buƙatar sarrafa yanayin zafin Laser daidai don tabbatar da daidaiton fitowar katako na Laser. Don haka na'urar walda ta Laser ya zama dole. TEYU Laser chiller manufacturer yana da fiye da shekaru 21 na Laser gwaninta sanyaya, tare da fiye da 90 kayayyakin aiki a kan 100 masana'antu. Misali, CWFL jerin chillers suna ba da yanayin sarrafa zafin jiki biyu don sanyaya Laser da na'urorin gani daban. Gargadin ƙararrawa da yawa, da ayyuka na Modbus-485, suna ba da tallafi mai ƙarfi don kyakkyawan aiki na walƙiya ta Laser.

Muna nan a gare ku lokacin da kuke buƙatar mu.

Da fatan za a cika fom ɗin don tuntuɓar mu, kuma za mu yi farin cikin taimaka muku.