Hiki ke pololei ka pololei o ka welding laser e like me ka 0.1mm mai ka lihi o ka uwea welding a hiki i ke kahawai kahe, ʻaʻohe haʻalulu, walaʻau, a lepo paha i ka wā o ke kaʻina hana kuʻi, e lilo ia i koho maikaʻi loa no nā koi kuʻi pololei o nā huahana plastik. A koi ʻia ka chiller laser e hoʻomalu pono i ka wela o ka laser e hōʻoia i ka paʻa o ka puka ʻana o ka laser beam.

Pono anei ʻo Microfluidics Laser Welding i kahi Laser Chiller?

Ua hoʻomohala ʻia nā Microfluidics i nā makahiki 1980 a pili i kahi ʻenehana no ka hoʻokele pololei a me ka hoʻoponopono ʻana i nā wai micro-scale, ʻoi aku ka nui o nā hale submicron. He ʻenehana interdisciplinary e pili ana i ka chemistry, fluid physics, microelectronics, mea hou, biology, a me biomedical engineering. Mahalo i kona liʻiliʻi liʻiliʻi, ka haʻahaʻa haʻahaʻa o ka ikehu, a me nā kapuaʻi mea liʻiliʻi, ʻoi aku ka maikaʻi o ka microfluidics no nā ʻano noi like ʻole i ka maʻi maʻi, ka loiloi biochemical, synthesis kemika, a me ka nānā ʻana i ke kaiapuni.

ʻO ke ʻano nui o ka microfluidic chips e pili ana i ka hoʻohui kumu o nā ʻāpana hana e pili ana i nā kula o ka kemika a me ka biology e like me ka hoʻomākaukau ʻana o ka laʻana, ka pane ʻana, ka hoʻokaʻawale ʻana, ka ʻike, ka moʻomeheu cell, ka hoʻokaʻawale ʻana, a me ka lysis i loko o kahi ʻāpana o nā kenimika square a i ʻole ma kahi pahu liʻiliʻi. Hoʻokumu ʻia kahi pūnaewele o nā microchannels, a holo ka wai hoʻomalu i ka ʻōnaehana holoʻokoʻa. Loaʻa i nā ʻāpana microfluidic nā mea maikaʻi e like me ka leo māmā, ka liʻiliʻi liʻiliʻi a me ka leo reagent, ka wikiwiki o ka hopena wikiwiki, ka hoʻoili like ʻana o ka nui, a me ka hoʻokuʻu ʻana i nā kula o ka biology, kemika, lāʻau lapaʻau, etc.

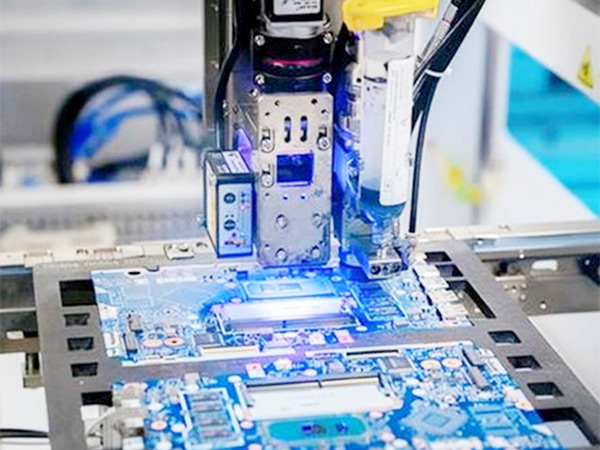

Hoʻonui ʻia ke kuʻekuʻe ʻana laser pololei i ka Microfluidic Chip

ʻO kahi puʻupuʻu microfluidic kahi puʻupuʻu liʻiliʻi i hoʻopaʻa ʻia i ka plastik e hoʻohui i nā ʻanuʻu he nui, me ka hoʻomākaukau ʻana i ka laʻana, nā hopena biochemical, a me ka ʻike hopena. Eia naʻe, no ka hoʻololi ʻana i ka helu o nā reagents i microliters a i ʻole nanoliters a i ʻole picoliters, ʻoi aku ka kiʻekiʻe o nā koi ʻenehana welding.

ʻO nā ʻenehana wiliwili maʻamau e like me ke kani ultrasonic, kaomi wela, a me ka gluing he mau hemahema. Hiki i ka ʻenehana kani ultrasonic ke kahe a me ka lepo, ʻoiai ʻo ka ʻenehana kaomi wela e hiki ke maʻalahi a hoʻoheheʻe ʻia, e hopena i ka hana haʻahaʻa.

ʻO ka wili laser, ma ka ʻaoʻao ʻē aʻe, he ʻenehana hoʻopili ʻole e hoʻohana ana i kahi kukuna laser lahilahi e hoʻohui i nā ʻāpana me ka pololei loa a me ka wikiwiki. ʻAʻole pili kēia ʻano i ke kahawai kahe, a hiki i ka pololei o ka wiliwili ke like me ka 0.1mm mai ka lihi o ka uea kuʻi a hiki i ke kahawai kahe. ʻAʻohe haʻalulu, walaʻau, a lepo paha i ka wā o ka hana kuʻi. ʻO ia ʻano hana kuʻi maʻemaʻe e lilo ia i koho kūpono no nā koi wili pololei o nā huahana plastik olakino.

Pono e hoʻolako ʻia ka welding laser me kahi pahu hau

No ka hoʻoponopono pololei ʻana i ka microfluidic chip, pono e hoʻomalu pono ka mīkini welding laser i ka wela o ka laser e hōʻoia i ka paʻa o ka puka ʻana o ka laser beam. No laila, pono ka laser welding chiller . Ua loaʻa iā TEYU laser chiller mea hana ma mua o 21 mau makahiki o ka hoʻomaʻamaʻa ʻana i ka laser, me nā huahana ʻoi aku ma mua o 90 e pili ana i nā ʻoihana 100. No ka laʻana, hāʻawi ka CWFL series chillers i kahi ʻano hoʻomalu wela ʻelua no ka hoʻoluʻu ʻana i ka laser a me nā optics kaʻawale. ʻO nā ʻōlelo aʻoaʻo hoʻāla he nui, a me nā hana Modbus-485, hāʻawi i ke kākoʻo ikaika no ka hana maikaʻi ʻana o ka welding laser.

Aia mākou ma ʻaneʻi no ʻoe ke makemake ʻoe iā mākou.

E ʻoluʻolu e hoʻopiha i ka palapala e hoʻokaʻaʻike mai iā mākou, a hauʻoli mākou e kōkua iā ʻoe.