Kurongeka kwelaser welding kunogona kuita senge 0.1mm kubva kumucheto kwewaya yewelding kuenda kune inoyerera chiteshi, iyo isingaite vibration, ruzha, kana guruva panguva yewelding process, zvichiita kuti ive sarudzo yakanaka kune chaiyo welding zvinodiwa zvemishonga yepurasitiki zvigadzirwa. Uye laser chiller inodiwa kunyatso kudzora tembiricha yelaser kuona kugadzikana kweiyo laser beam kubuda.

Ko Microfluidics Laser Welding Inoda Laser Chiller?

Microfluidics yakagadzirwa mu1980s uye inoreva tekinoroji yekunyatso kudzora uye mashandisirwo ezvinwiwa zvidiki-diki, kunyanya submicron zvimiro. Iyo tekinoroji yekudyidzana inosanganisira chemistry, fluid fizikisi, microelectronics, zvinhu zvitsva, biology, uye biomedical engineering. Nekuda kwehukuru hwayo hudiki, kuderera kwesimba rekushandisa, uye diki mudziyo tsoka, microfluidics iri kuvimbisa zvakanyanya kune akasiyana mashandisirwo mukuongororwa kwekurapa, kuongororwa kwebiochemical, makemikari synthesis, uye kuongorora kwezvakatipoteredza.

Iyo yakajairwa fomu yemicrofluidic machipisi inoreva kubatanidzwa kwekutanga kwemayuniti anoshanda anobatanidzwa mundima yekemesitiri uye biology seyemuenzaniso kugadzirira, kuita, kupatsanurwa, kuona, sero tsika, kuronga, uye lysis muchidimbu che akati wandei sikweya masendimita kana kunyange padiki chip. Network ye microchannels inoumbwa, uye mvura inodzoreka inofamba nepakati pese system. Microfluidic machipisi ane akati wandei mabhenefiti senge mwenje vhoriyamu, shoma sampuli uye reagent vhoriyamu, kukurumidza kuita kukurumidza, hukuru-hukuru hwakafanana kugadzirisa, uye kuraswa muminda yebiology, chemistry, mushonga, nezvimwe.

Precision Laser Welding Inowedzera Microfluidic Chip

A microfluidic chip ipurasitiki diki-based chip inobatanidza matanho akawanda, kusanganisira kugadzirira sampuli, biochemical reaction, uye mhedzisiro yekuona. Nekudaro, kushandura huwandu hwema reagents kuita mamicroliters kana kunyange nanoliters kana picoliters, iyo welding tekinoroji zvinodiwa zvakakwirira zvakanyanya.

Maitiro akajairwa welding senge ultrasonic, kupisa kupisa, uye gluing zvine zvinokanganisa. Ultrasonic tekinoroji inotapukira uye guruva, nepo kupisa kudzvanya tekinoroji inogona kukanganisa uye kufashama zviri nyore, zvichikonzera kushomeka kwekugadzira.

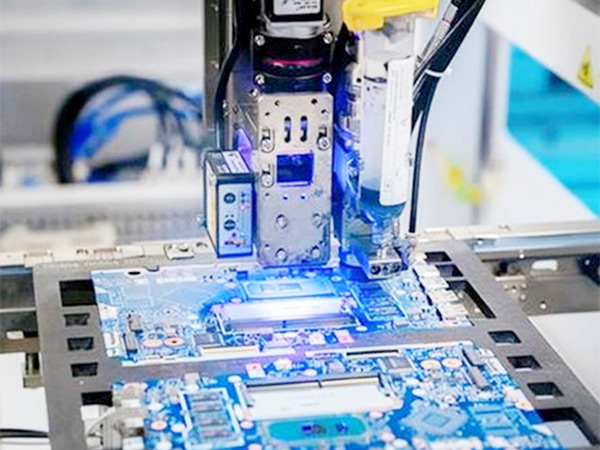

Laser welding, kune rumwe rutivi, inzira isingabatanidzi welding iyo inoshandisa yakaonda laser danda kubatanidza zvikamu nekunyanya kurongeka uye nekumhanya. Iyi nzira haikanganisi chiteshi chekuyerera, uye kurongeka kwewelding kunogona kuve kwakajeka se 0.1mm kubva kumucheto kwewaya yewelding kuenda kune inoyerera chiteshi. Iko hakuna vibration, ruzha, kana guruva panguva yewelding process. Yakadaro yakachena welding nzira inoita kuti ive sarudzo yakanaka kune chaiyo welding zvinodiwa zvemishonga yepurasitiki zvigadzirwa.

Laser Welding Inofanirwa Kushongedzerwa neLaser Chiller

Kune microfluidic chip precision process, iyo laser welding muchina inoda kunyatso kudzora tembiricha yelaser kuti ive nechokwadi chekugadzikana kweiyo laser beam kubuda. Saka laser welding chiller inodiwa. TEYU laser chiller mugadziri ane anopfuura makore makumi maviri nerimwe e laser kutonhora ruzivo, aine zvinopfuura makumi mapfumbamwe zvigadzirwa zvinoshanda kune anopfuura zana maindasitiri. Semuyenzaniso, CWFL yakatevedzana chillers inopa mbiri tembiricha yekudzora modhi yekutonhodza laser uye optics zvakasiyana. Multiple alarm yambiro, uye Modbus-485 mabasa, inopa rutsigiro rwakasimba rwekugadzirisa kwakanaka kwelaser welding.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.