Ukuchaneka kwe-laser welding kunokuchaneka njenge-0.1mm ukusuka kumda we-welding welding ukuya kumjelo wokuhamba, okungekho kungcangcazela, ingxolo, okanye uthuli ngexesha lenkqubo ye-welding, okwenza kube lukhetho olufanelekileyo kwiimfuno ze-welding ezichanekileyo zeemveliso zeplastiki zonyango. Kwaye i-laser chiller iyafuneka ukulawula ngokuchanekileyo ubushushu be-laser ukuqinisekisa ukuzinza kwemveliso ye-laser beam.

Ngaba iMicrofluidics Laser Welding ifuna iLaser Chiller?

I-Microfluidics yaphuhliswa kwiminyaka yee-1980 kwaye ibhekisela kwithekhnoloji yokulawula ngokuchanekileyo kunye nokuphathwa kwe-micro-scale fluids, ngakumbi izakhiwo ze-submicron. Bubuchwephesha obubandakanya i-chemistry, i-fluid physics, i-microelectronics, izixhobo ezitsha, i-biology, kunye nobunjineli be-biomedical. Ngombulelo kumthamo omncinci, ukusetyenziswa kwamandla aphantsi, kunye nesixhobo esincinci, i-microfluidics ithembisa kakhulu kwiinkqubo ezahlukeneyo zokuxilongwa kwezonyango, uhlalutyo lwe-biochemical, i-chemical synthesis, kunye nokubeka iliso kwindalo.

Uhlobo oluqhelekileyo lwe-microfluidic chips lubhekiselele ekudityanisweni okusisiseko kweeyunithi zokusebenza ezibandakanyekayo kwiinkalo zekhemistri kunye nebhayoloji ezifana nokulungiswa kwesampulu, ukusabela, ukwahlula, ukufumanisa, inkcubeko yeseli, ukuhlenga, kunye ne-lysis kwisiqwenga seesentimitha ezininzi zesikwere okanye nakwi-chip encinci. Inethiwekhi ye-microchannels yenziwa, kwaye ulwelo olulawulekayo luhamba kuyo yonke inkqubo. Iitshiphusi zeMicrofluidic zineengenelo ezininzi ezinje ngevolumu yokukhanya, isampulu encinci kunye nevolumu yereagent, isantya sokuphendula ngokukhawuleza, ukusetyenzwa okukhulu okuhambelanayo, kunye nokulahlwa kwiinkalo zebhayoloji, ikhemistri, iyeza, njl.

I-Precision Laser Welding Yongeza i-Microfluidic Chip

I-microfluidic chip yi-chip encinci esekelwe kwiplastiki edibanisa amanyathelo amaninzi, kubandakanywa ukulungiswa kwesampuli, ukuphendulwa kwe-biochemical, kunye nokufumanisa iziphumo. Nangona kunjalo, ukuguqula inani le-reagents kwi-microliters okanye i-nanoliters okanye i-picoliters, iimfuno zobuchwepheshe be-welding ziphezulu kakhulu.

Iindlela eziqhelekileyo ze-welding ezifana ne-ultrasonic, ukucinezela ubushushu, kunye ne-gluing zinemiqobo. Itekhnoloji ye-Ultrasonic ithanda ukuchitheka kunye nothuli, ngelixa itekhnoloji yokucinezela eshushu inokuguqula ngokulula kunye nokuphuphuma, okukhokelela ekusebenzeni okuphantsi kwemveliso.

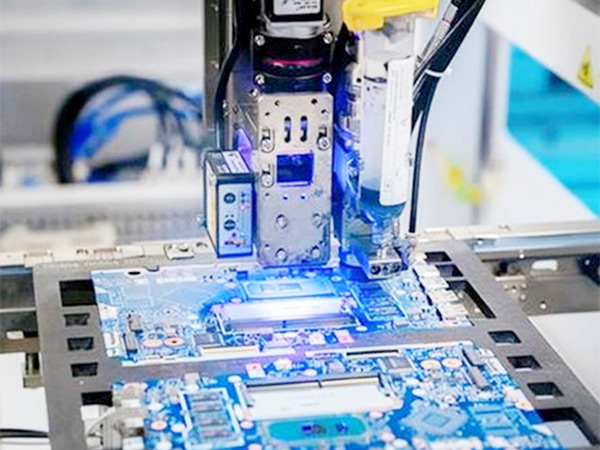

I-laser welding, kwelinye icala, yindlela yokudibanisa i-non-contact esebenzisa umqadi we-laser obhityileyo ukudibanisa iindawo ngokuchaneka okugqithisileyo kunye nesantya. Le ndlela ayinakuchaphazela umzila wokuhamba, kwaye ukuchaneka kwe-welding kunokuchaneka njenge-0.1mm ukusuka kumda we-wire welding ukuya kumjelo wokuhamba. Akukho ngcangcazelo, ingxolo, okanye uthuli ngexesha lenkqubo yewelding. Indlela ye-welding ecocekileyo iyenza ibe lukhetho olufanelekileyo kwiimfuno ezichanekileyo ze-welding yeemveliso zeplastiki zonyango.

Ukuwelda ngeLaser kufuneka kuxhotyiswe ngeChiller yeLaser

Kwi-microfluidic chip precision processing, umatshini we-laser welding kufuneka ulawule ngokuchanekileyo ubushushu be-laser ukuqinisekisa ukuzinza kwemveliso ye-laser beam. Ngaloo ndlela i -laser welding chiller iyimfuneko. Umvelisi we-laser chiller we-TEYU uneminyaka engaphezu kwe-21 yamava okupholisa nge-laser, kunye neemveliso ezingaphezu kwama-90 ezisebenza kumashishini angaphezu kwe-100. Umzekelo, ii-CWFL series chillers zibonelela ngemowudi yolawulo lobushushu obubini bokupholisa i-laser kunye ne-optics ngokwahlukeneyo. Izilumkiso ezininzi ze-alamu, kunye nemisebenzi ye-Modbus-485, inikezela ngenkxaso eqinile yokulungiswa kakuhle kwe-laser welding.

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.