Ukunemba kwe-laser welding kungaba okunembe njengo-0.1mm ukusuka onqenqemeni lwentambo yokushisela kuya esiteshini sokugeleza, okungenawo ukudlidliza, umsindo, noma uthuli ngesikhathi senqubo yokushisela, okukwenza kube ukukhetha okuhle kwezidingo zokushisela ezinembayo zemikhiqizo yepulasitiki yezokwelapha. Futhi i-laser chiller iyadingeka ukuze kulawulwe ngokunembile izinga lokushisa le-laser ukuze kuqinisekiswe ukuzinza kokuphuma kwe-laser beam.

Ingabe I-Microfluidics Laser Welding Idinga I-Laser Chiller?

I-Microfluidics yasungulwa ngeminyaka yawo-1980s futhi ibhekisela kubuchwepheshe bokulawula okunembayo kanye nokuxhaphaza uketshezi lwesikali esincane, ikakhulukazi izakhiwo ze-submicron. Ubuchwephesha obuhlukahlukene obuhlanganisa ikhemistri, i-fluid physics, i-microelectronics, izinto ezintsha, i-biology, kanye nobunjiniyela be-biomedical. Ngenxa yomthamo wayo omncane, ukusetshenziswa kwamandla okuphansi, kanye nezinyathelo ezincane zedivayisi, i-microfluidics ithembisa kakhulu ezinhlobonhlobo zezinhlelo zokusebenza ekuxilongweni kwezokwelapha, ukuhlaziya amakhemikhali ezinto eziphilayo, ukuhlanganiswa kwamakhemikhali, nokuqapha indawo ezungezile.

Ifomu elivamile lama-microfluidic chips libhekisela ekuhlanganisweni okuyisisekelo kwamayunithi okusebenza abandakanyekayo emikhakheni yamakhemikhali nesayensi yezinto eziphilayo njengokulungiselela isampula, ukusabela, ukuhlukaniswa, ukutholwa, isiko lamaseli, ukuhlunga, kanye ne-lysis ibe ucezu lwamasentimitha-skwele ambalwa noma ngisho ku-chip encane. Inethiwekhi yamashaneli amancane ayakhiwa, futhi uketshezi olulawulekayo lugijima kulo lonke uhlelo. Ama-chips e-Microfluidic anezinzuzo ezimbalwa ezifana nevolumu ekhanyayo, isampula encane nevolumu ye-reagent, isivinini sokuphendula ngokushesha, ukucubungula okukhulu okuhambisanayo, nokulahlwa emkhakheni webhayoloji, ikhemistri, imithi, njll.

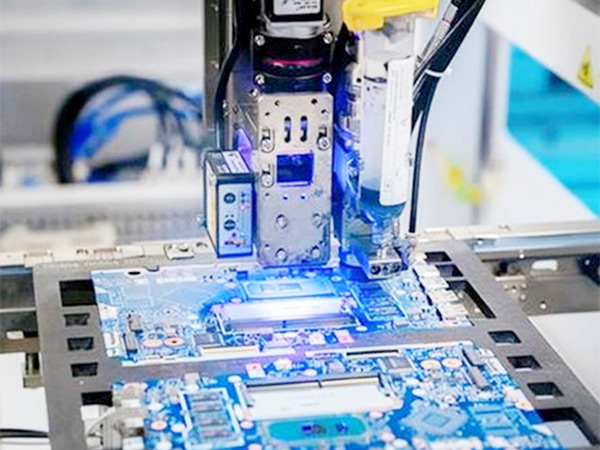

I-Precision Laser Welding Ithuthukisa I-Microfluidic Chip

I-microfluidic chip iyi-chip encane esekwe epulasitiki ehlanganisa izinyathelo eziningi, okuhlanganisa ukulungiswa kwesampula, ukusabela kwe-biochemical, nokutholwa kwemiphumela. Kodwa-ke, ukuguqula inani lama-reagents abe ama-microliter noma ama-nanoliter noma ama-picoliters, izidingo zobuchwepheshe bokushisela ziphezulu kakhulu.

Izindlela zokushisela ezijwayelekile njenge-ultrasonic, ukucindezela ukushisa, ne-gluing zinezithiyo. Ubuchwepheshe be-Ultrasonic bujwayele ukuchitheka nothuli, kuyilapho ubuchwepheshe bokucindezela okushisayo bungakhubaza kalula futhi buchichime, okuholela ekusebenzeni kahle kokukhiqiza.

I-laser welding, ngakolunye uhlangothi, iyindlela yokushisela engathinteki esebenzisa ugongolo oluncane lwe-laser ukuxhuma izingxenye ngokunemba okukhulu nangesivinini. Le ndlela ayithinti umzila wokugeleza, futhi ukunemba kwe-welding kungaba okunembe njengo-0.1mm ukusuka onqenqemeni lwentambo yokushisela ukuya esiteshini sokugeleza. Akukho ukudlidliza, umsindo, noma uthuli phakathi nenqubo yokushisela. Indlela yokushisela ehlanzekile enjalo ikwenza kube ukukhetha okuhle kwezidingo zokushisela ezinembayo zemikhiqizo yepulasitiki yezokwelapha.

I-Laser Welding Kumele Ifakwe I -Laser Chiller

Ukuze kucutshungulwe ukunemba kwe-microfluidic chip, umshini wokushisela we-laser udinga ukulawula ngokunembile izinga lokushisa le-laser ukuze uqinisekise ukuzinza kokuphumayo kwe-laser beam. Ngakho-ke, i -laser welding chiller iyadingeka. Umkhiqizi we-laser chiller we-TEYU uneminyaka engaphezu kwengama-21 yesipiliyoni sokupholisa nge-laser, enemikhiqizo engaphezu kuka-90 esebenza ezimbonini ezingaphezu kwe-100. Isibonelo, ama-chiller ochungechunge lwe-CWFL ahlinzeka ngemodi yokulawula izinga lokushisa embaxambili yokupholisa i-laser kanye nezinto ezibonakalayo ngokuhlukana. Izexwayiso zama-alamu amaningi, nemisebenzi ye-Modbus-485, inikeza ukwesekwa okuqinile kokucutshungulwa okuhle kwe-laser welding.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.