Laser welding muchina unogona kusanganisa zvinhu zvemhando dzakasiyana, ukobvu hwakasiyana uye maumbirwo akasiyana kuburikidza nelaser simba kuitira kuti chidimbu chebasa chakapedzwa chiwane kuita kwakanyanya kubva kuchikamu chimwe nechimwe.

Laser welding ndechimwe chezvakakosha chikamu mukugadzirisa laser. Iine yakakwira simba laser danda senzvimbo yekupisa, laser welding ndiyo yakakwira chaiyo welding nzira. Inoshandisa yakakwira simba Laser danda kupisa kumusoro kwechigamba chebasa uye ipapo kupisa kunopararira kubva pane zvinhu kusvika mukati. Nemaparamendi eiyo laser pulse paramita ari kugadziridzwa, iyo laser beam simba inonyungudutsa zvinhu uyezve yakanyungudutswa yekugezera inoumbwa.

Laser welding muchina unogona kusanganisa zvinhu zvemhando dzakasiyana, ukobvu hwakasiyana uye maumbirwo akasiyana kuburikidza nelaser simba kuitira kuti chidimbu chebasa chakapedzwa chiwane kuita kwakanakisa kubva kuchikamu chimwe nechimwe.

Saka chii chakanakira laser welding muchina mune yakaonda simbi kugadzirwa?

Stainless simbi ine yakafara chikumbiro mumaindasitiri akasiyana. Uye yakaonda Stainless simbi welding yave nzira yakakosha mukugadzirwa kwesimbi, asi iyo yakasarudzika yesimbi yakaonda Stainless simbi inoita kuti zviome kuita welding pairi. Saka iyo yakatetepa Stainless welding yaimbova dambudziko guru.

Sezvatinoziva, simbi yakatetepa isina tsvina ine diki kwazvo kupisa conductivity coefficient inongori 1/3 yeyakajairwa yakaderera kabhoni simbi. Naizvozvo, kana zvimwe zvikamu zvaro zvagamuchira kudziyisa uye kutonhora panguva yekugadzira welding, zvinogadzira kusagadzikana kusagadzikana uye kunetsa. The vertical contraction ye weld line ichaita humwe huwandu hwekushushikana pamucheto wesimbi yakaonda isina tsvina. Iyo drawback yekushandisa yechinyakare welding muchina pane yakaonda Stainless simbi inodarika iyi. Kupisa uye deformation zvakare musoro chaiwo kune vanogadzira simbi.

Asi ikozvino, kuuya kwelaser welding muchina kunogadzirisa dambudziko iri. Laser welding muchina unoratidzira diki weld mutsara wakafara, kudziya kudiki kunobata nzvimbo, kudiki deformation, yakakwira welding kumhanya, yakanaka weld mutsara, kusununguka kweautomation, hapana bubble uye hapana chinodiwa chekuomesera post-processing. Nezvese zvakanakira izvi, laser welding muchina uri kutsiva yechinyakare welding muchina.

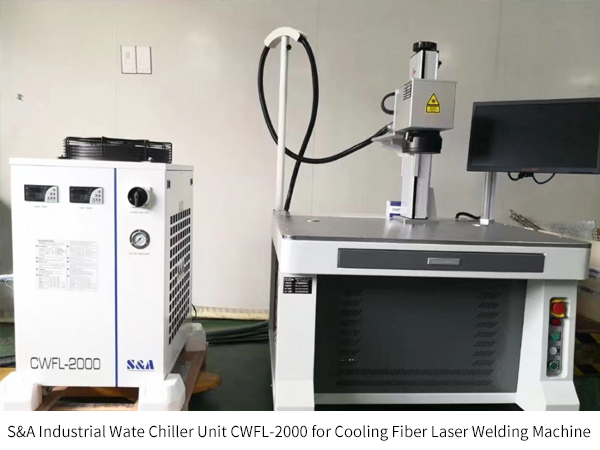

Mazhinji emalaser welding michina inoshandiswa mukugadzirwa kwesimbi yakatetepa inofambiswa nefiber laser kubva pa500W kusvika 2000W. Fiber lasers emhando iyi iri nyore kugadzira kupisa kwakawanda. Kana kupisa ikoko kusingagone kubviswa nenguva, zvinokonzeresa kukuvadza kwakanyanya kune fiber laser uye kupfupisa hupenyu hwayo. Nemaindasitiri emvura chiller unit, kupisa harisi dambudziko zvakare. S&A Teyu CWFL yakatevedzana maindasitiri emvura chiller unit ndiyo yakakwana yekutonhora mhinduro kune fiber laser kubva pa500W kusvika 20000W. Iwo CWFL akatevedzana maindasitiri emvura ekuchiller mayunitsi anogovana chinhu chimwe chete - iwo ese ane maviri akazvimirira ekutonhodza maseketi. Imwe ndeyekutonhodza iyo fiber laser uye imwe ndeyekutonhodza musoro welaser. Iyi mhando yedhizaini haingonatsiridza kushanda kwefiriji chete asiwo inochengetedza nzvimbo yevashandisi, sezvo ikozvino CHIller MUMWE chete anogona kupedza basa rekutonhodza revaviri. Kunze kwezvo, tembiricha yekudzora tembiricha inobva pa5-35 degree C, iyo inokwana zvakakwana kupa kutonhora kwakanaka kwefiber laser welding michina. Tsvaga zvimwe nezve CWFL yakatevedzana maindasitiri emvura chiller unit pa https://www.teyuchiller.com/fiber-laser-chillers_c2