Umshini wokushisela we-laser ungahlanganisa izinto zezinhlobo ezahlukene, ukujiya okuhlukile kanye nokwakheka okuhlukile ngokusebenzisa amandla e-laser ukuze ucezu oluqediwe lomsebenzi lungathola ukusebenza okuhle kakhulu engxenyeni ngayinye.

I-laser welding ingenye yezingxenye ezibaluleke kakhulu ekucutshungulweni kwe-laser. Ngomgodi we-laser wamandla aphezulu njengomthombo wokushisa, i-laser welding iyindlela yokushisela enembayo ephezulu. Isebenzisa i-laser yamandla aphezulu ukuze ishise ingaphezulu lesiqephu somsebenzi bese ukushisa kuzosabalala kusuka endaweni ebonakalayo kuye ngaphakathi. Njengoba amapharamitha we-laser pulse parameters elungiswa, amandla e-laser beam azoncibilikisa izinto bese kwakheka ukugeza okuncibilikisiwe.

Umshini wokushisela we-laser ungahlanganisa izinto zezinhlobo ezahlukene, ukujiya okuhlukene kanye nokubunjwa okuhlukile ngokusebenzisa amandla e-laser ukuze ucezu lomsebenzi oluqediwe lungathola ukusebenza okuhle kakhulu engxenyeni ngayinye.

Ngakho-ke yini inzuzo yomshini wokushisela we-laser ekukhiqizeni insimbi encane?

Insimbi engagqwali inesicelo esibanzi ezimbonini ezahlukene. Futhi i-welding encane yensimbi engagqwali ibe yinqubo ebalulekile ekukhiqizeni insimbi, kodwa isici esiyingqayizivele sensimbi encane engagqwali senza kube nzima ukwenza i-welding kuso. Ngakho ukushisela insimbi engagqwali ezacile kwakuvame ukuba inselele enkulu.

Njengoba sazi, insimbi encane engagqwali ine-coefficient encane kakhulu yokushisa ukushisa okuyi-1/3 kuphela yensimbi ye-carbon low evamile. Ngakho-ke, uma ezinye zezingxenye zayo zithola ukufudumeza nokupholisa ngesikhathi senqubo yokushisela, kuzokwakha ukucindezeleka nokucindezeleka okungalingani. Ukufinyela okuqondile komugqa we-weld kuzokwakha inani elithile lokucindezeleka emaphethelweni ensimbi encane engagqwali. I-drawback yokusebenzisa umshini wokushisela wendabuko ensimbi encane engagqwali ingaphezu kwalokhu. Ukushiswa nokuguqulwa kubuye kube yikhanda langempela labakhi bensimbi.

Kodwa manje, ukufika komshini wokushisela we-laser kuyixazulula ngokuphelele le nselele. Umshini wokushisela we-laser unobubanzi bomugqa we-weld omncane, ukushisa okuncane okuthinta indawo, ukuwohloka okuncane, isivinini esikhulu sokushisela, ulayini wokushisela omuhle, ukusebenziseka kalula, akukho bubble futhi asikho isidingo sokusebenza kwangemuva okuyinkimbinkimbi. Ngazo zonke lezi zinzuzo, umshini wokushisela we-laser kancane kancane ushintsha umshini wokushisela wendabuko.

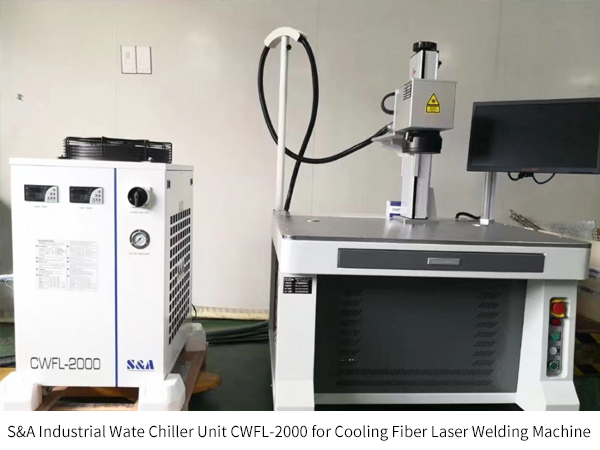

Iningi lemishini yokushisela i-laser esetshenziswa ekukhiqizeni insimbi emincane inikwa amandla yi-fiber laser kusuka ku-500W kuya ku-2000W. Ama-fiber lasers alolu hlu kulula ukukhiqiza ukushisa okuningi. Uma lokho kushisa kungakwazi ukuchithwa ngesikhathi, kuzodala umonakalo omkhulu ku-fiber laser futhi kufinyeze ubude bayo bempilo. Ngeyunithi ye-industrial water chiller, ukushisa ngokweqile akuseyona inkinga. S&A Iyunithi ye-Teyu CWFL yochungechunge lwe-industrial chiller yamanzi iyisixazululo esiphelele sokupholisa se-fiber laser esukela ku-500W kuya ku-20000W. Amayunithi okupholisa amanzi ochungechunge lwe-CWFL abelana ngento eyodwa efanayo - wonke anamasekhethi amabili okupholisa azimele. Enye ngeyokupholisa i-fiber laser kanti enye eyokupholisa ikhanda le-laser. Lolu hlobo lomklamo aluthuthukisi ukusebenza kahle kwesiqandisi kuphela kodwa futhi lulondoloza isikhala kubasebenzisi, njengoba manje umshini opholile OWODWA kuphela ongaqeda umsebenzi wokupholisa kokubili. Ngaphandle kwalokho, uhla lokulawula izinga lokushisa lusuka ku-5-35 degree C, olwanele ukuhlinzeka ngokupholisa okuphumelelayo kwemishini yokushisela i-fiber laser. Thola ulwazi oluthe xaxa mayelana neyunithi ye-CWFL yezimboni zokupholisa amanzi ku -https://www.teyuchiller.com/fiber-laser-chillers_c2