With the continuous development of picosecond laser technology, infrared picosecond lasers are now a reliable choice for precise glass cutting. The picosecond glass cutting technology used in laser cutting machines is easy to control, non-contact, and produces less pollution. This method ensures clean edges, good verticality, and low internal damage, making it a popular solution in the glass-cutting industry. For high-precision laser cutting, temperature control is crucial to ensure efficient cutting at the specified temperature. TEYU S&A CWUP-40 laser chiller boasts a temperature control accuracy of ±0.1℃ and features a dual temperature control system for optics circuit and laser circuit cooling. It includes multiple functions to address processing problems promptly, minimize loss, and enhance processing efficiency.

A New Solution for Precision Glass Cutting | TEYU S&A Chiller

Glass is a notoriously hard and brittle material widely used in various industries, such as consumer electronics, automobiles, and optical lenses. However, as market demands continue to rise, ordinary glass processing methods no longer meet the required level of precision.

New Solution for Precision Glass Cutting

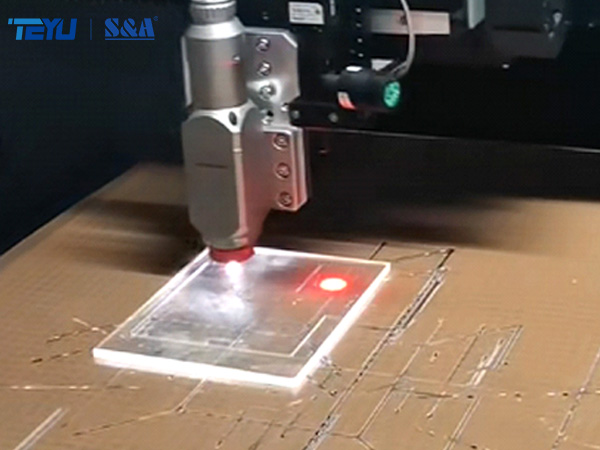

With the continuous development of picosecond laser technology, infrared picosecond lasers are now a reliable choice for precise glass cutting. By utilizing the characteristics of low thermal energy diffusion, picosecond cutting achieves material interruption before heat conduction to surrounding materials, resulting in cutting brittle materials with greater ease. With lower pulse energy, picosecond cutting also attains peak light intensity and delivers outstanding results.

The ultrashort pulse generated by the laser interacts with the material for a very short time. When the laser pulse width reaches the picosecond or femtosecond level, it can avoid the influence on the thermal movement of molecules and will not bring thermal influence to the surrounding materials. Therefore, this laser processing is also known as cold processing. Laser "cold processing" can reduce melting and heat-affected zones, with less recasting of materials, resulting in fewer microcracks in materials, surface ablation quality, less laser absorption dependence on materials and wavelengths, and has low heat and cold ablation features, suitable for the processing of brittle materials such as glass.

Non-contact laser processing not only reduces the cost of mold development but also eliminates edge chipping and cracks that can occur with traditional cutting methods. This highly precise and efficient method produces clean cutting edges, eliminating the need for secondary processing such as washing, grinding, and polishing. By improving production efficiency and the yield of finished products, this method can help users reduce costs and increase efficiency.

The picosecond glass cutting technology used in laser cutting machines is easy to control, non-contact, and produces less pollution, making it a green and environmentally friendly option for customers. Precision glass laser cutting ensures clean edges, good verticality, and low internal damage, making it a popular solution in the glass-cutting industry.

Laser Chiller - Essential Cooling System for Precision Glass Laser Cutting

For high-precision laser cutting, temperature control is crucial to ensure efficient cutting at the specified temperature. A dedicated chiller is necessary to regulate the temperature of the laser and laser head, maintaining a stable laser output rate and ensuring normal, high-speed operation of the device.

TEYU S&A laser chiller CWUP-40 boasts a temperature control accuracy of ±0.1℃ and features a dual temperature control system for optics circuit and laser circuit cooling. With dual functionality, this machine is incredibly convenient. Additionally, it includes multiple alarm functions to address processing problems promptly, minimize loss, and enhance processing efficiency.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.