Dab tsi cuam tshuam rau cov txiaj ntsig ntawm high-speed laser cladding? Cov yam ntxwv tseem ceeb yog laser tsis, cov yam ntxwv ntawm cov khoom, ib puag ncig tej yam kev mob, substrate mob thiab pre-kho txoj kev, scanning lub tswv yim thiab txoj kev tsim. Rau ntau tshaj 22 xyoo, TEYU Chiller Chaw tsim tshuaj paus tau tsom mus rau kev lag luam laser txias, xa cov chillers xws li 0.3kW txog 42kW los ua kom muaj ntau hom laser cladding khoom cua txias xav tau.

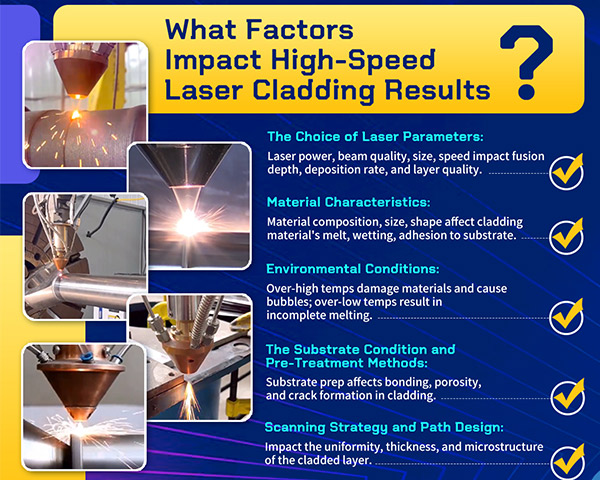

Dab tsi cuam tshuam rau cov txiaj ntsig ntawm High-speed Laser Cladding?

Kev kub ceev laser cladding tau tshwm sim los ua ib txoj hauv kev hloov pauv hauv cov khoom siv, txhim khu kev ua tau zoo thiab qhov tseeb ntawm kev hloov kho deg thiab cov khoom tso tawm. Koj puas paub dab tsi cuam tshuam rau kev kub ceev laser cladding tau? Cia peb tshawb nrhiav:

1. Laser Parameters. Cov kev hloov pauv xws li lub zog laser, kab teeb pom kev zoo, qhov chaw loj, thiab kev nrawm nrawm ntsuas qhov tob ntawm fusion, cov ntaub ntawv tso tawm tus nqi, thiab tag nrho qhov zoo ntawm txheej txheej. Kev xaiv qhov zoo tshaj plaws yog qhov tseem ceeb heev kom ua tiav cov khoom uas xav tau thaum ua kom muaj qhov tsis zoo thermal tsawg.

2. Cov yam ntxwv ntawm cov khoom: muaj pes tsawg leeg, particle loj, thiab morphology ntawm lub laser cladding khoom profoundly cuam tshuam nws meltability, wettability, thiab adhesion rau lub substrate. Compatibility ntawm substrate thiab cladding cov ntaub ntawv yog qhov tseem ceeb rau kev ua tau zoo dua kev sib txuas.

3. Ib puag ncig tej yam kev mob: ambient kub, av noo, thiab roj ib puag ncig thaum lub sij hawm cladding txheej txheem yog ib qho tseem ceeb heev. Piv txwv li, qhov kub siab tshaj tuaj yeem ua rau cov khoom puas tsuaj, ua rau npuas, thiab cuam tshuam cov qauv, thaum qhov kub thiab txias ua rau tsis tiav melting, teeb meem solidification, thiab tsis zoo adhesion, cuam tshuam rau laser cladding zoo. Txhawm rau tiv thaiv qhov kub thiab txias hauv laser cladding, lub tshuab laser chiller feem ntau yog siv.

4. Cov txheej txheem substrate thiab kev kho ua ntej. Deg roughness, huv si, thiab preheating ntawm lub substrate cuam tshuam lub zog sib txuas, porosity, thiab tawg tsim nyob rau hauv lub cladded txheej. Kev npaj txaus ntawm substrate nto yog qhov tseem ceeb los ua kom zoo dua qhov adhesion thiab kev ncaj ncees ntawm cladding.

5. Kev Tshawb Fawb Lub Tswv Yim thiab Txoj Kev Tsim: ua rau muaj kev cuam tshuam zoo heev rau qhov sib xws, tuab, thiab microstructure ntawm txheej cladded. Precision nyob rau hauv kev tswj lub laser beam txav thiab overlapping lem kom zoo ib yam deposition thiab xav tau txhua yam khoom.

Rau ntau tshaj 22 xyoo, TEYU Chiller Chaw tsim tshuaj paus tau tsom mus rau kev lag luam laser txias, xa cov chillers xws li 0.3kW txog 42kW los ua kom muaj ntau hom laser cladding khoom cua txias xav tau. Yog tias koj txaus siab, cia li xav paub ntxiv ntawm Fiber Laser Chiller , lossis xa email ncaj qha rausales@teyuchiller.com kom tau txais koj cov kua txias tshwj xeeb.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.