Yiziphi izici ezithinta imiphumela ye-laser cladding enesivinini esikhulu? Izici eziyinhloko zomthelela imingcele ye-laser, izici ezibonakalayo, izimo zemvelo, isimo se-substrate nezindlela zokwelashwa kwangaphambili, isu lokuskena kanye nokwakhiwa kwendlela. Ngaphezu kweminyaka engama-22, i-TEYU Chiller Manufacturer igxile ekupholiseni nge-laser yezimboni, iletha amakhaza asukela ku-0.3kW kuya ku-42kW ukuze ahlinzekele izidingo zokupholisa zemishini yokuvala nge-laser eyahlukahlukene.

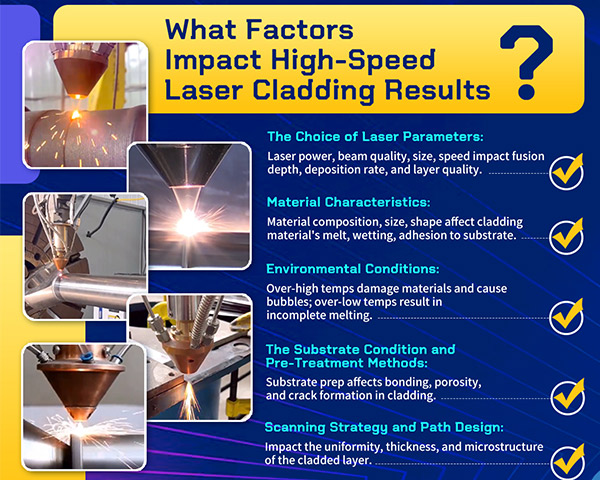

Yiziphi Izinto Ezinomthelela emiphumeleni ye-High-speed Laser Cladding?

Ukugqokwa kwe-laser enesivinini esiphezulu kuvele njengendlela yokuguqula ekucutshungulweni kwezinto, okuthuthukisa ukusebenza kahle nokunemba kokuguqulwa kwendawo kanye nokubekwa kwezinto ezibonakalayo. Uyazi ukuthi yiziphi izinto ezithinta imiphumela ye-laser cladding enesivinini esikhulu? Ake sihlole:

1. Laser Amapharamitha. Okuguquguqukayo okunjengamandla e-laser, ikhwalithi ye-beam, usayizi wendawo, nesivinini sokuskena sinquma ukujula kokuhlanganisa, izinga lokubekwa kwezinto ezibonakalayo, kanye nekhwalithi iyonke yesendlalelo esihlanganisiwe. Ukukhetha okufanelekile kwepharamitha kubalulekile ukuze kuzuzwe izakhiwo ezifiselekayo ezingaphezulu ngenkathi uqinisekisa ukuhlanekezela okushisayo okuncane.

2. Izimpawu Zezinto Ezibalulekile: ukwakheka, usayizi wezinhlayiyana, kanye nokuma kwe-laser cladding material kuthonya kakhulu ukuncibilika kwayo, ukumanzisa, nokunamathela kwayo ku-substrate. Ukuhambisana phakathi kwe-substrate ne-cladding material kubalulekile ukuze kuzuzwe ukubopha okuphakeme.

3. Izimo Zemvelo: izinga lokushisa lendawo, umswakama, nendawo yegesi ngesikhathi senqubo yokumboza kubalulekile. Isibonelo, amazinga okushisa aphakeme kakhulu angonakalisa izinto ezisetshenziswayo, abangele amabhamuza, futhi aphazamise izakhiwo, kuyilapho amazinga okushisa aphansi kakhulu eholela ekuncibilikeni okungaphelele, ezinkingeni zokuqinisa, nokunamathela okubi, okuthinta ikhwalithi yokuvala i-laser. Ukubhekana nokulawulwa kwezinga lokushisa ku-laser cladding, iyunithi yokupholisa i-laser ivame ukusetshenziswa.

4. Isimo Se-Substrate kanye Nezindlela Zokwelapha Ngaphambili. Ubulukhuni bobuso, ukuhlanzeka, kanye nokushisisa kwangaphambili kwe-substrate kuthonya amandla okubopha, i-porosity, nokwakheka kokuqhekeka kungqimba oluhlanganisiwe. Ukulungiswa okwanele kwendawo ye-substrate kubalulekile ukuze kwandiswe ukunamathela nobuqotho be-cladding.

5. Isu Lokuskena kanye Nomklamo Womzila: kuthonya kakhulu ukufana, ukujiya, kanye nesakhiwo esincane sesendlalelo esihlanganisiwe. Ukunemba ekulawuleni ukunyakaza kwe-laser beam namathrekhi agqagqene kuqinisekisa ukubekwa okungaguquguquki kanye nezakhiwo ezifiselekayo zemishini.

Ngaphezu kweminyaka engama-22, i-TEYU Chiller Manufacturer igxile ekupholiseni nge-laser yezimboni, iletha amakhaza asukela ku-0.3kW kuya ku-42kW ukuze ahlinzekele izidingo zokupholisa zemishini yokuvala nge-laser eyahlukahlukene. Uma uthanda, vele ukhululeke ukufunda okwengeziwe ku -Fiber Laser Chiller , noma thumela i-imeyili kuyosales@teyuchiller.com ukuze uthole isisombululo sakho sokupholisa esikhethekile.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.