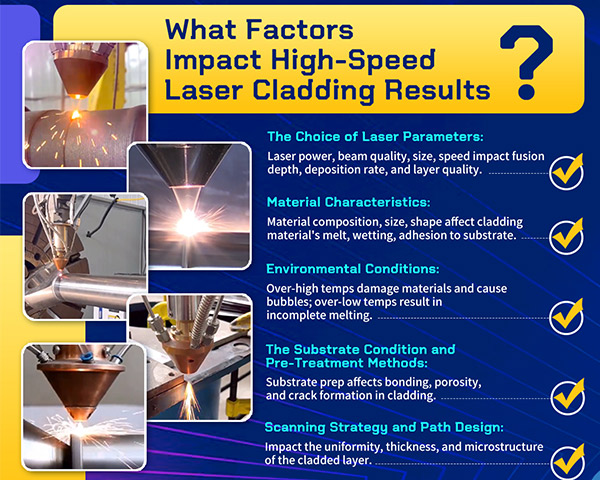

Ndezvipi zvinhu zvinokanganisa mhedzisiro yeyakakwira-kumhanya laser cladding? Izvo zvakanyanya kukanganisa zvinhu laser paramita, hunhu hwezvinhu, mamiriro ezvakatipoteredza, substrate mamiriro uye pre-kurapa nzira, scanning zano uye nzira dhizaini. Kweanopfuura makore makumi maviri nemaviri, TEYU Chiller Manufacturer yakatarisana neindasitiri yekutonhora kwelaser, kuendesa machiller kubva pa0.3kW kusvika 42kW kuti ape kune akasiyana laser cladding midziyo yekutonhodza zvinodiwa.

Ndezvipi Zvinhu Zvinokanganisa Mhedzisiro dzeHigh-speed Laser Cladding?

High-speed laser cladding yakabuda senzira yekushandura mukugadzirisa zvinhu, ichiwedzera kushanda uye kunyatsoita kwekugadzirisa kwepamusoro uye kuisa zvinhu. Iwe unoziva here kuti ndezvipi zvinhu zvinokanganisa yakakwira-kumhanya laser cladding mhinduro? Ngationgororei:

1. Laser Parameters. Zvinosiyana zvakadai sesimba relaser, mhando yedanda, saizi yemavara, uye yekumhanyisa kumhanya inoraira kudzika kwefusion, chiyero chekuisa zvinhu, uye huwandu hwese hweiyo yakavharwa layer. Optimal parameter kusarudzwa kwakakosha kuti uwane inodiwa pamusoro pezvivakwa uku uchiona kushoma kwemafuta kukanganisa.

2. Material Characteristics: kuumbwa, particle size, uye morphology ye laser cladding material inonyanya kukanganisa kunyunguduka kwayo, kunyorova, uye kunamatira kune substrate. Kuenderana pakati pe substrate uye cladding zvinhu kwakakosha kuti uwane yepamusoro chisungo.

3. Environmental Conditions: ambient tembiricha, humidity, uye gasi nharaunda panguva cladding process anokosha. Semuenzaniso, tembiricha yepamusoro-soro inogona kukanganisa zvinhu, kukonzera mabhubhu, uye kukanganisa zvimiro, nepo tembiricha yakadzikira-inotungamira mukunyungudika kusina kukwana, nyaya dzekusimba, uye kusanamatira zvakanaka, zvichikanganisa mhando yelaser cladding. Kugadzirisa tembiricha yekudzora mune laser cladding, laser chiller unit inowanzoshandiswa.

4. The Substrate Condition uye Pre-Kurapwa Nzira. Kushata kwepamusoro, kuchena, uye kudziya kweiyo substrate kunokanganisa simba rekubatanidza, porosity, uye kuumbwa kwekutsemuka mune yakavharwa layer. Kugadzirira kwakakwana kwe substrate pamusoro kwakakosha kuti uwedzere kunamatira uye kutendeseka kweiyo cladding.

5. Kuongorora Strategy uye Nzira Dhizaini: inokanganisa zvakanyanya kufanana, ukobvu, uye microstructure yeyakavharwa layer. Kunyatso kudzora kufamba kwelaser beam uye kupindirana mateki kunovimbisa kuenderana kudhirowa uye inodiwa michina zvivakwa.

Kweanopfuura makore makumi maviri nemaviri, TEYU Chiller Manufacturer yakatarisana neindasitiri yekutonhora kwelaser, kuendesa machiller kubva pa0.3kW kusvika 42kW kuti ape kune akasiyana laser cladding midziyo yekutonhodza zvinodiwa. Kana uchifarira, ingonzwa wakasununguka kudzidza zvakawanda paFiber Laser Chiller , kana kutumira email kunesales@teyuchiller.com kuti uwane yako yega yekutonhodza mhinduro.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.