Kune indasitiri ye mold, kunyangwe laser yekucheka uye laser welding ichiita senge isingawane kushandiswa kwayo kwakaringana, laser kuchenesa kwave kuwedzera kushandiswa mukuumbwa kwepamusoro kurapwa, kupfuura echinyakare kuchenesa.

Laser yekuchenesa inokunda echinyakare kuchenesa mukuumbwa kwepamusoro kurapwa

Laser processing tekinoroji ikozvino yakajairika mumaindasitiri akasiyana siyana. Kune indasitiri ye mold, kunyangwe laser yekucheka uye laser welding ichiita senge isingawane kushandiswa kwayo kwakaringana, laser kuchenesa kwave kuwedzera kushandiswa mukuumbwa kwepamusoro kurapwa, kupfuura echinyakare kuchenesa.

Kana zvasvika pakuumbwa, zviri nyore kunzwisisa. Kubva pakugadzira keke kusvika kune hombe indasitiri muchina, inoda mold kuti ipedze. Nyika yedu ine bhizinesi rakakura kwazvo rekugadzira pasirese uye muchina wega wega weindasitiri une mhando dzakasiyana siyana dzinoda mold dzakasiyana.

Sezvo mold ichida kusanganidzana neyepamusoro tembiricha zvinhu kana inoda kutarisana nechibhakera kana kushushikana, kazhinji inogadzirwa kubva kusimbi.

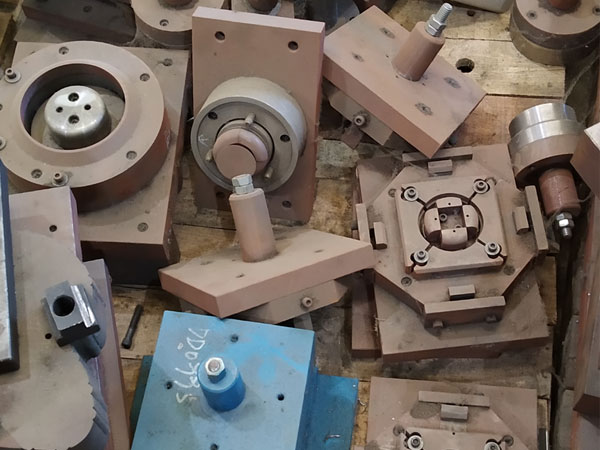

Mukushandiswa chaiko, pane kazhinji kune mamwe matambudziko ekukurumidzira anoda kugadziriswa mukuumbwa. Uye iyo inonyanya kukosha ndeyekucheneswa kwe mold. Mamwe maumbirwo esimbi anoshandiswa kuve prototyping yekushisa kwakanyanya kunyunguduka zvinhu. Kana zvigadzirwa zvapedza uye zvabviswa kubva muhuturu, kazhinji pane zvakasara zvezvinhu zvakasara pazviumbwa. Izvi zvinoda kuti vanhu vachenese mold, nekuti izvi zvinokanganisa kugadzirwa kwechigadzirwa chinotevera, asi izvo zvingatora nguva.

Uyezve, zviumbwa zviri nyore kuita ngura. Sezvo mazhinji ezviumbwa zveindasitiri akagadzirwa nesimbi, anozoita ngura mushure mekushandiswa kwenguva yakati rebei. Uye zviumbwa zvinoda kucheneswa zvakanaka zvisati zvashandiswa pamushini. Nekudaro, kucheneswa kwechinyakare kwaizodhura basa rakakura uye mutengo, izvo zvakashata kune vanogadzira.

Asi kubvira kucheneswa kwelaser kuchiunzwa mukuchenesa mold, zvinhu zvave zvakasiyana. Laser yekuchenesa inoshandisa yakakwira simba uye yakakwira frequency laser mwenje pane mold pamusoro kuitira kuti zvakasara, ngura, oi tsvina, nezvimwe zvinogona kubuda kubva pachiumbwa chepamusoro kana kuve chidimbu ipapo. Unogona kuona mhedzisiro yekuchenesa laser. Kana iyo laser beam ichifamba pamusoro pechinhu chepamusoro, nzvimbo yacho inogona kunyatso kuchena mukati memasekondi.

Mazuva ano, kuchenesa kwelaser kunogona kuitwa zvine mutsindo panzvimbo yakati sandara, yakakombama, gomba uye gap. Iyo yakajairika handheld laser yekuchenesa muchina yatove inoshanda pakubvisa ngura kubva kune zvakajairika simbi molds uye nguva yekuchenesa ingori 1/10 yekucheneswa kwechinyakare. Kunze kwezvo, vagadziri vazhinji vava kufunga kuisa laser yekuchenesa michina pamitsetse yekugadzira mold kuti vaone kutarisa uye otomatiki kuchenesa zvakasara pazviumbwa, izvo zvinoshanda zvakanyanya.

Laser yekuchenesa tekinoroji yava kuwedzera kukura. Kubva pane yekutanga 200W kusvika nhasi 2000W, laser yekuchenesa muchina unogona kuita zvakanyanya uye zvakanyanya kuchenesa. Naizvozvo, ine ramangwana rakanaka muindasitiri yekuumbwa. Kune michina yekuchenesa laser ine masimba akasiyana, S&A Chiller inogona kupa yakakodzera laser water chillers kuti ienderane navo uye kutonhora kwesimba kunogona kusvika 30KW. Isu tanga tichibatsira vazhinji vanoshandisa laser yekuchenesa muchina kugadzirisa dambudziko rekupisa.

S&A Chiller anga achigadzira uye kugadzira laser mvura chiller kwemakore makumi maviri. Vanovhara inenge yese laser application. Isu tiri kugara takaisa ziso pane nyowani yekushandisa muindasitiri yelaser uye nekuvandudza machiller anofanana nawo. Nekugara tichivandudza, tave zita rinozivikanwa mumusika wekutonhora welaser.

Kune yedu yakadzama laser water chiller modhi, tinya https://www.teyuchiller.com/products

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.