Kwishishini lokungunda, nangona ukusika i-laser kunye ne-laser welding kubonakala ngathi ayikufumani ukusetyenziswa kwayo ngokufanelekileyo okwangoku, ukucocwa kwe-laser kuye kwasetyenziswa kakhulu kunyango lomphezulu wokubumba, ukodlula ukucocwa kwendabuko.

Ukucocwa kweLaser kugqwesa ukucocwa kwemveli kunyango lomphezulu womngundo

Ubuchwephesha bokucutshungulwa kweLaser ngoku buxhaphake kakhulu kumashishini ahlukeneyo. Kwishishini lokungunda, nangona ukusika i-laser kunye ne-laser welding kubonakala ngathi ayikufumani ukusetyenziswa kwayo ngokufanelekileyo okwangoku, ukucocwa kwe-laser kuye kwasetyenziswa kakhulu kunyango lomphezulu wokubumba, ukodlula ukucocwa kwendabuko.

Xa kuziwa kubumba, kulula ukuyiqonda. Ukusuka ekwenzeni ikeyiki ukuya kumatshini omkhulu wemizi-mveliso, kufuna ukungunda ukugqiba. Ilizwe lethu linelona shishini likhulu lemveliso yehlabathi kwaye wonke umatshini wemizi-mveliso uneentlobo ezahlukeneyo ezifuna ukungunda okwahlukileyo.

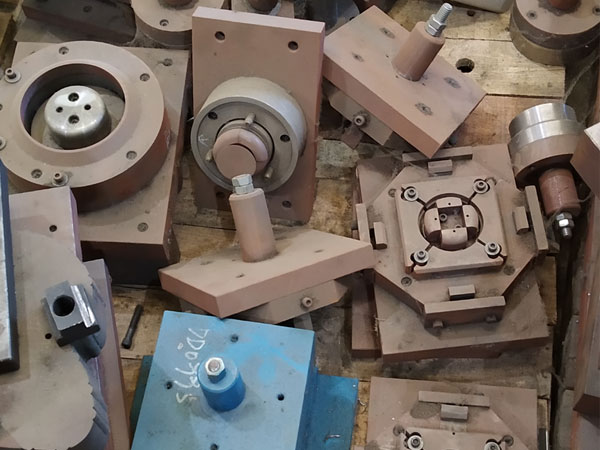

Ekubeni isikhunta kufuneka sidibane nobushushu obuphezulu okanye kufuneka sijongane ne-punch okanye uxinzelelo, luhlala lusenziwa ngentsimbi.

Kusetyenziso lwangempela, kuhlala kukho iingxaki ezingxamisekileyo ezifuna ukusonjululwa kubumba. Kwaye eyona nto ibalulekileyo kukucocwa kwesikhunta. Ezinye izinto zokubumba zentsimbi zisetyenziselwa ukuba ngumzekelo wezinto ezinyibilikayo zobushushu obuphezulu. Xa iimveliso zigqityiwe kwaye zikhutshwe kwi-molds, ngokuqhelekileyo kukho intsalela yezinto eziphathekayo ezishiywe kwiimbumba. Oku kufuna ukuba abantu bacoce umngundo, kuba oku kuyakuchaphazela ukwenziwa kwemveliso elandelayo, kodwa oko kuya kuthatha ixesha elininzi.

Ngaphezu koko, ukungunda kulula ukuba nomhlwa. Kuba uninzi lokubumba kweshishini lwenziwe ngentsimbi, luya kuba nomhlwa emva kokusetyenziswa ixesha elithile. Kwaye umngundo kufuneka ucocwe kakuhle phambi kokuba usetyenziswe kumatshini. Nangona kunjalo, ukucoca ngokwesiko kuya kubiza umsebenzi omkhulu kunye neendleko, nto leyo embi kakhulu kubavelisi.

Kodwa ukusukela oko ukucocwa kwelaser kwaziswa ekucoceni umngundo, izinto ziye zahluka. Ukucocwa kweLaser kusebenzisa amandla aphezulu kunye nokukhanya okuphezulu kwe-laser kwindawo yokubumba ukuze intsalela, irusi, i-oi stain, njl. Unokubona umphumo wokucoca nge-laser. Xa umqa welaser uhamba kumphezulu wezinto eziphathekayo, umphezulu unokucoceka kwimizuzwana nje.

Kule mihla, ukucocwa kwelaser kunokwenziwa ngokufanelekileyo kumphezulu osicaba, umphezulu ogobileyo, umngxuma kunye nesithuba. Umatshini wokucoca we-laser oqhelekileyo ophathwa ngesandla sele usebenza ngokugqibeleleyo ekususeni umhlwa kwiimbumba zesinyithi ngokubanzi kwaye ixesha lokucoca yi-1/10 kuphela yokucoca ngokwesintu. Ngaphandle koko, abaninzi abavelisi ngoku baqwalasela ukufaka oomatshini bokucoca i-laser kwimigca yokuvelisa i-mold ukuze baqonde ukubeka iliso kunye nokucoca ngokuzenzekelayo intsalela yezinto eziphathekayo kwiimbumba, esebenza kakuhle kakhulu.

Indlela yokucoca iLaser iye yakhula ngakumbi nangakumbi. Ukususela kwi-200W yokuqala ukuya kwi-2000W namhlanje, umatshini wokucoca nge-laser unokwenza ucoceko olunzima ngakumbi. Ke ngoko, inekamva elikhulu kwishishini lokungunda. Ngoomatshini bokucoca nge-laser abanamandla ahlukeneyo, S&A i-Chiller inokubonelela nge -laser water chillers efanelekileyo ukuze ihambelane nabo kunye nomthamo wokupholisa unokufikelela kwi-30KW. Siye sanceda abasebenzisi abaninzi bomatshini wokucoca i-laser ukusombulula ingxaki yokutshisa.

S&A I-Chiller iphuhlisa kwaye ivelisa i-laser water chillers iminyaka engama-20. Bagubungela phantse lonke usetyenziso lwelaser. Sihlala sibeke iliso kwisicelo esitsha kwishishini le-laser kunye nokuphuhlisa izitshizi ezihambelana nazo. Ngokuzihlaziya rhoqo, siye saba luphawu olwaziwayo kwimarike yokupholisa i-laser.

Ngeemodeli zethu ezineenkcukacha ze-laser zokupholisa amanzi, cofa ku-https://www.teyuchiller.com/products

Silapha ngenxa yakho xa usidinga.

Nceda ugcwalise ifomu ukuze uqhagamshelane nathi, kwaye siya kukuvuyela ukukunceda.