Waldawar Ultrasonic hanya ce ta tafi-da-gidanka don abubuwan haɗin filastik daban-daban a cikin kayan lantarki, motoci, kayan wasan yara, da kayan masarufi. A halin yanzu, walda laser yana samun kulawa, yana ba da fa'idodi na musamman. Kamar yadda Laser roba waldi ya ci gaba da girma a kasuwa aikace-aikace da kuma bukatar mafi girma ikon tashi, masana'antu chillers zai zama wani muhimmin zuba jari ga mutane da yawa masu amfani.

Ta yaya Kasuwar Gyaran Filastik Laser Za ta Iya Karye Sabon Gari?

Filastik, ɗaya daga cikin abubuwan ƙirƙira mafi kyawun ɗan adam, yanzu yana da alaƙa a cikin dubban sassa, daga marufi zuwa kayan lantarki, motoci, kiwon lafiya, da sauran su. Tare da versatility, filastik za a iya classified a matsayin ko dai m ko sassauƙa da kuma ana gyare-gyare ta hanyoyi kamar extrusion, busa gyare-gyare, da allura gyare-gyare. Wasu kayan aikin an shirya su a mataki ɗaya, yayin da wasu suna buƙatar ƙarin gyare-gyare don biyan buƙatun samfur na ƙarshe.

Haɗu da Buƙatun Haɓaka don sarrafa Filastik: Matsayin Welding Laser

Yawancin sassan filastik ana iya haɗa su kai tsaye bayan yin gyare-gyare. Koyaya, samfuran hadaddun galibi suna buƙatar abubuwan filastik don gyara ko haɗa su da wasu kayan. Saboda nau'ikan robobi daban-daban, zabar hanyar sarrafawa da kayan aiki da suka dace - waɗanda aka keɓance da kaddarorin filastik - yana da mahimmanci.

A halin yanzu, galibin sarrafa robobi sun dogara ne akan dabarun injuna, gami da sarewa, sarewa, hakowa, niƙa, goge baki, da zaren zare. Robobin masana'antu na yau da kullun, irin su PP, ABS, PET, PVC, da acrylic, galibi ana yanke su da igiyoyin gani na inji, waɗanda suka dogara sosai akan aikin hannu. Wannan sau da yawa yana haifar da al'amurra tare da madaidaici, ƙananan lahani, da buƙatar kammala sakandare don cire burrs.

Don hakowa, aikin injina ne aka fi amfani da shi don kayan aikin filastik. Saboda dabi'ar polymers na filastik don lalacewa ta hanyar raƙuman aikin ƙarfe, hakowa na inji yana da sauri amma sau da yawa yana samar da tarkacen filastik da burrs tare da gefuna. Duk da wadannan kura-kurai, hakowa injina ya kasance mafi girma da shaharar hanya don abubuwan filastik.

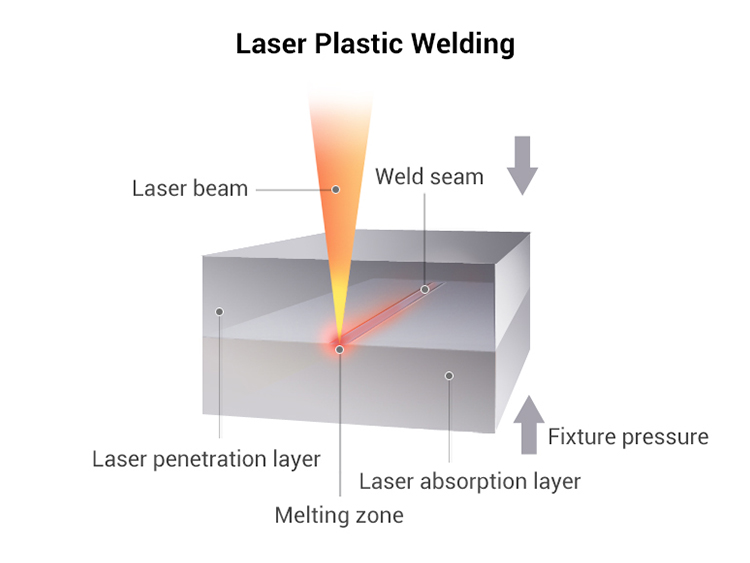

Bari mu dubi fasahar walda ta filastik. Filastik yana da zafi, don haka walda shi yawanci ya haɗa da narkewa ko laushi don haɗa sassa. Dabarun kamar walƙiya farantin zafi sun dace da manyan ɓangarorin filastik tare da faɗin wuraren tuntuɓar juna.

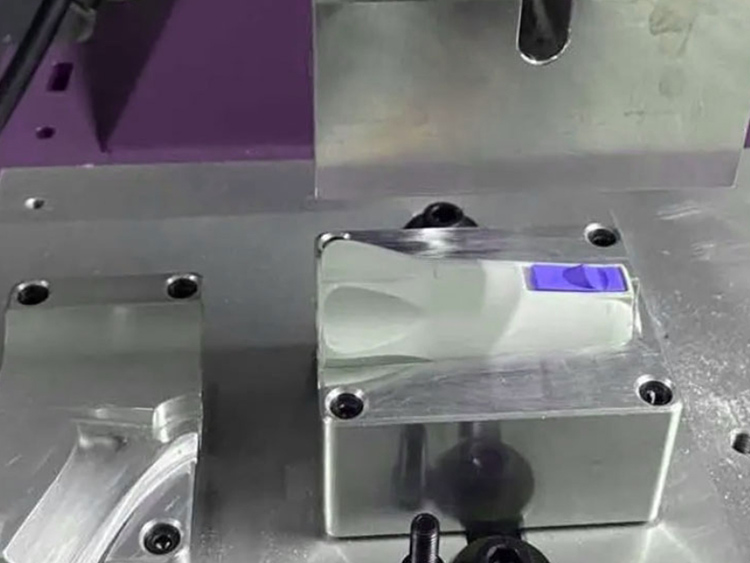

(Ultrasonic Welding)

Waldawar Ultrasonic ita ce hanyar tafi-da-hannun kayan aikin filastik daban-daban a masana'antu kamar na'urorin lantarki, motoci, kayan wasa, kayan kwalliya, da kayan masarufi. Wannan hanyar tana amfani da ƙarfin injina mai ƙarfi don samar da zafi nan take da haɗin saman filastik.

A halin yanzu, walda Laser - sabuwar hanya - yana samun kulawa. Ta hanyar amfani da zafin da aka samar da Laser daidai a haɗin gwiwa, walƙiya na laser yana ba da fa'idodi na musamman. Wadanne nasarori masu yuwuwa na laser zai iya kawowa ga sarrafa filastik?

Bincika Ƙwararren Ƙwararriyar Laser a Masana'antar Filastik: Ƙananan Farashin Kayan Kayan aiki na iya zama Fa'ida

An riga an yi amfani da alamar Laser sosai wajen sarrafa robobi, musamman don yiwa abubuwa lakabi kamar igiyoyi, caja, da cakuɗen kayan aiki. Fasahar yin alama ta Laser UV ta balaga kuma ta dace da ƙara tambura tambura ko cikakkun bayanan samfur akan filayen filastik.

Don yankan da hakowa, duk da haka, sarrafa Laser yana fuskantar ƙalubale. Ƙunƙarar zafi na filastik na iya haifar da narkewa ko ƙonewa, yana da wuya a cimma tsaftataccen yanke ba tare da duhu ko ƙona gefuna ba. Duk da yake har yanzu ba za a iya yanke robobi na zahiri tare da lasers ba, robobi masu duhu suna da yuwuwar tare da babban mitoci, manyan lase masu bugun jini. Kamar yadda fasahar Laser ta ci gaba-musamman a cikin lasers na bugun jini na ultrashort - yankan filastik na iya ƙara zama mai yiwuwa.

Kamar yadda aka ambata, walda Laser na robobi sabon fasaha ne wanda ke ba da fa'idodi kamar saurin sauri, daidaitaccen madaidaici, hatimi mai ƙarfi, tsari mara ƙazanta, da ƙaƙƙarfan gidajen abinci, dacewa da aikace-aikace a cikin motoci, na'urorin likitanci, da na'urorin lantarki masu amfani. Duk da haka, duk da kasancewa a kasuwa na shekaru da yawa, waldi na filastik Laser ya kasance alkuki, galibi ƙalubalen kayan aikin ultrasonic. Kudi wani batu ne, tare da injunan walda robobi na Laser da ke kashe dubun-dubatar yuan, yayin da injunan ultrasonic ke kashe 'yan dubbai. Bugu da ƙari, hanyoyin laser har yanzu suna buƙatar ƙarin bincike don nau'ikan robobi daban-daban. Ultrasonic waldi kuma dace da sarrafa kansa aiki tare da babban gudun da kuma yadda ya dace, ko da yake yana da amo gurbatawa al'amurran da suka shafi da ƙananan daidaici da sealing fiye da Laser waldi.

Tare da ci gaba da raguwa a cikin Laser da farashin kayan aiki masu alaƙa, farashin injunan walda na filastik Laser na iya faɗuwa zuwa ¥ 100,000 ($ 13,808) ko ƙasa da haka a nan gaba, yana jawo ƙarin masu amfani. Yayin da bincike ke zurfafawa, musamman a cikin adadin sha tsakanin robobi masu haske da masu launi da siffa ta al'ada, waldawar Laser don robobi na iya ganin ci gaba.

An mayar da hankali kan Filin Tallafi na Laser Plastic Processing: TEYU S&A Chiller a cikin Haske.

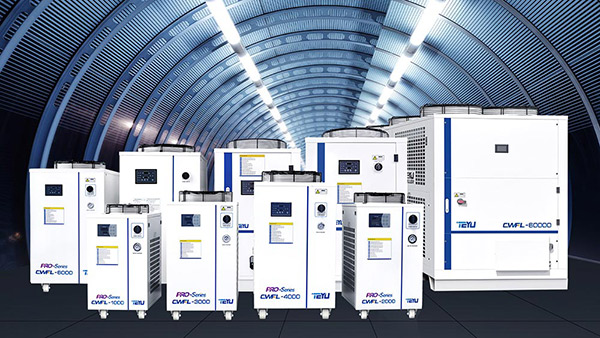

Tare da haɓaka buƙatun don walƙar filastik mai inganci a cikin masana'antu daban-daban, fasahar walƙiya ta filastik Laser tana samun shahara. Ci gaba da haɓaka kasuwar walda ta filastik Laser shima yana haɓaka buƙatar samfuran kayan haɗi na Laser, mai yuwuwar haifar da haɓakar kayan aikin walda na Laser.

A matsayin muhimmin bangaren kayan walda na filastik Laser, tsarin sanyaya suna taka muhimmiyar rawa wajen sarrafa zafin jiki. Tare da shekaru 22 na gwaninta a fasahar sanyaya Laser, Guangzhou Teyu Electromechanical Co., Ltd. (wanda aka fi sani da TEYU S&A Chiller) ya haɓaka kewayon chillers masana'antu wanda ya dace da yawancin samfuran gida da na duniya na fiber Laser, Laser UV, CO2 Laser kayan aiki, da kayan aikin injin CNC. Wadannan chillers suna rufe kusan dukkanin nau'ikan Laser da manyan jeri na wutar lantarki, kuma suna da babban kaso na kasuwa a sashin walda na filastik.

A cikin wannan filin, TEYU S&A masana'antu chillers sun dace sosai tare da kayan walda na laser na zamani. Misali, TEYU S&A chiller masana'antu CW-5200 yana ba da daidaitaccen kwanciyar hankali na ± 0.3 ℃, yana aiki akan ƙarfin mitar 220V 50/60Hz, kuma yana goyan bayan yanayin sarrafa zafin jiki na dindindin da na hankali. Tare da fasalulluka kamar ƙarfin sanyaya ƙarfi, ƙirar eco-friendly, rayuwar sabis na tsawon lokaci, da ingantaccen daidaito, yana tabbatar da cewa injunan walda na filastik Laser suna kula da yanayin zafi mafi kyau.

Kamar yadda Laser aiki-musamman Laser roba waldi-ci gaba da girma a kasuwa aikace-aikace da kuma bukatar mafi girma iko tashi, masana'antu chillers zai zama wani muhimmin zuba jari ga mutane da yawa masu amfani.

Muna nan a gare ku lokacin da kuke buƙatar mu.

Da fatan za a cika fom ɗin don tuntuɓar mu, kuma za mu yi farin cikin taimaka muku.