I-Ultrasonic welding iyindlela yokuya ezintweni ezahlukahlukene zepulasitiki kugesi, izimoto, amathoyizi, kanye nezimpahla zabathengi. Ngaleso sikhathi, i-laser welding ithola ukunakwa, inikeza izinzuzo eziyingqayizivele. Njengoba i-laser plastic welding iqhubeka nokukhula ekusetshenzisweni kwemakethe kanye nesidingo sokukhuphuka kwamandla aphezulu, ama-chiller ezimboni azoba utshalomali olubalulekile kubasebenzisi abaningi.

Imakethe Yokucubungula Ipulasitiki Ye-Laser Ingayiphula Kanjani Indawo Entsha?

Ipulasitiki, enye yezinto eziqanjwe abantu ezishintsha kakhulu, manje isiyingxenye yezinkulungwane zemikhakha, kusukela emaphaketheni kuye kwekagesi, ezezimoto, ezokunakekelwa kwempilo nokunye. Ngokuguquguquka kwayo, ipulasitiki ingahlukaniswa njengeqinile noma eguquguqukayo futhi ibunjwa ngezinqubo ezifana ne-extrusion, i-blow molding, kanye nokubumba komjovo. Ezinye izingxenye sezenziwe ngomumo ngesinyathelo esisodwa, kanti ezinye zidinga ukucolisiswa okwengeziwe ukuze zihlangabezane nezimfuneko zomkhiqizo wokugcina.

Ukuhlangabezana Nesidingo Esikhulayo Sokucutshungulwa Kwepulasitiki: Iqhaza Le-Laser Welding

Izingxenye eziningi zepulasitiki zingahlanganiswa ngokuqondile ngemva kokubunjwa. Kodwa-ke, imikhiqizo eyinkimbinkimbi ivame ukudinga ukuthi izingxenye zepulasitiki zilungiswe noma zihlanganiswe nezinye izinto. Ngenxa yezinhlobonhlobo zamapulasitiki, ukukhetha indlela efanele yokucubungula kanye nemishini—efanelana nezakhiwo zepulasitiki ngayinye—kubalulekile.

Njengamanje, ukucutshungulwa kwepulasitiki okuningi kuncike kumasu emishini, okuhlanganisa ukusaha, ukugunda, ukubhoboza, ukugaya, ukupholishwa, nokuhlanganisa. Amapulasitiki ezimboni ajwayelekile, njenge-PP, ABS, PET, PVC, kanye ne-acrylic, ngokuvamile asikwa ngama-saw blades, ancike kakhulu ekusebenzeni okwenziwa ngesandla. Lokhu kuvame ukuholela ezinkingeni ngokunemba, amanani aphezulu wokukhubazeka, kanye nesidingo sokuqeda okwesibili ukuze kukhishwe ama-burrs.

Ukubhoboza, ukubhola ngomshini yizona ezisetshenziswa kakhulu ezingxenyeni zepulasitiki. Ngenxa yokuthambekela kokuthi ama-polymer epulasitiki alinyazwe izingcezu zokubhola zensimbi, ukubhola ngomshini kuyashesha kakhulu kodwa kuvame ukukhiqiza udoti wepulasitiki kanye nama-burrs emaphethelweni. Naphezu kwalezi zihibe, ukubhola ngomshini kusalokhu kuyindlela evuthiwe nethandwa kakhulu yezingxenye zepulasitiki.

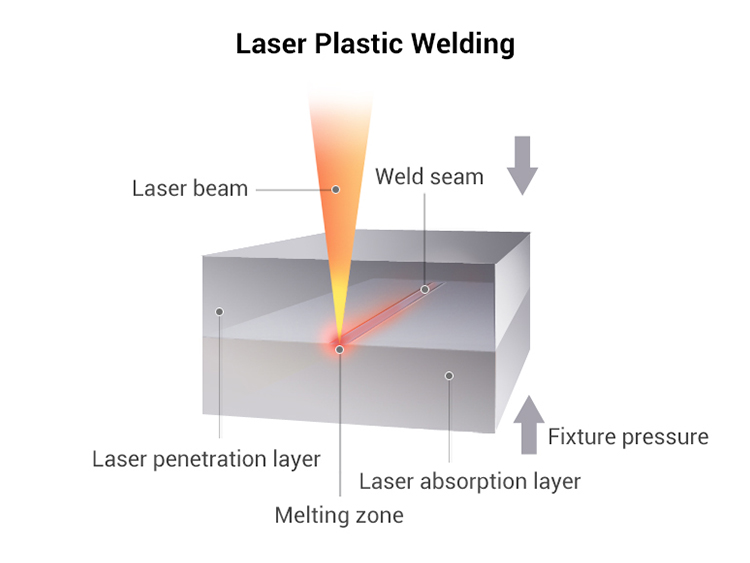

Ake sihlolisise ubuchwepheshe be-plastic welding. Ipulasitiki ayizwani nokushisa, ngakho ukuyishisela ngokuvamile kuhilela ukuncibilika noma ukuthambisa ukuze uhlanganise izingxenye. Amasu afana ne-hot plate welding ahambisana nezingcezu ezinkulu zepulasitiki ezinezindawo zokuxhumana ezibanzi.

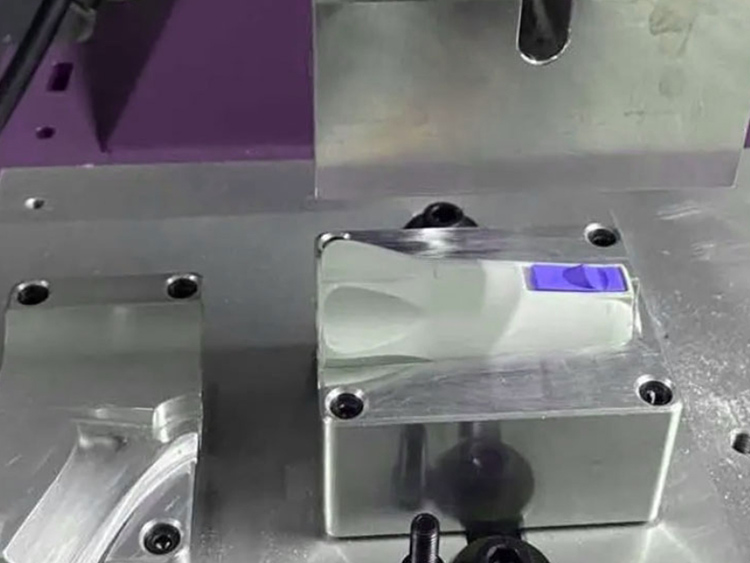

(I-Ultrasonic Welding)

I-Ultrasonic welding iyindlela yokuhamba yezingxenye zepulasitiki ezahlukahlukene ezimbonini ezifana ne-electronics, izimoto, amathoyizi, izimonyo, kanye nempahla yabathengi. Le ndlela isebenzisa amandla emishini anemvamisa ephezulu ukuze ikhiqize ukushisa osheshayo nebhondi yepulasitiki.

Ngaleso sikhathi, ukushisela nge-laser—indlela entsha—kuyanakwa. Ngokusebenzisa ukushisa okukhiqizwa nge-laser ngokuqondile ejoyintini, i-laser welding inikeza izinzuzo eziyingqayizivele. Yimiphi impumelelo engaba khona engaletha i-laser ekucutshungulweni kwepulasitiki?

Ukuhlola Amandla Okucubungula I-Laser Ekwenziweni Kwepulasitiki: Izindleko Zezinto Eziphansi Zingase Zibe Yinzuzo

Ukumaka nge-laser sekuvele kusetshenziswa kabanzi ekucutshungulweni kwepulasitiki, ikakhulukazi ekulebulani kwezinto ezifana namakhebuli, amashaja, namakesi ezinto zikagesi. Ubuchwepheshe bokumaka ngelaser ye-UV buvuthiwe futhi bufaneleka kahle ukwengeza amalogo omkhiqizo noma imininingwane yomkhiqizo endaweni yepulasitiki.

Ukusika nokubhoboza, nokho, ukucutshungulwa kwe-laser kubhekana nezinselelo. Ukuzwela ukushisa kwepulasitiki kungaholela ekuncibilikeni noma ekushiseni, okwenza kube nzima ukufeza ukusikeka okuhlanzekile ngaphandle kwemiphetho emnyama noma eshile. Yize ipulasitiki esobala ingakakwazi ukusikwa ngamalaser, amapulasitiki amnyama anamandla anemvamisa ephezulu, amalaser anamandla aphezulu. Njengoba ubuchwepheshe be-laser buthuthuka-ikakhulukazi kuma-laser we-ultrashort pulse-ukusika kwepulasitiki kungase kusebenze kakhulu.

Njengoba sekushiwo, i-laser welding of plastics ubuchwepheshe obusha obunikeza izinzuzo ezifana nesivinini esisheshayo, ukunemba okuphezulu, izimpawu eziqinile, inqubo yokungangcoli, namajoyinti aqinile, afanele ukusetshenziswa ezimotweni, kumishini yezokwelapha, nakugesi wabathengi. Kodwa-ke, naphezu kokuba semakethe iminyaka eminingana, i-laser plastic welding ihlala iyi-niche, ikakhulukazi inselele imishini ye-ultrasonic. Izindleko ziwudaba olulodwa, ngemishini yokushisela ipulasitiki ye-laser ebiza amashumi ezinkulungwane zama-yuan, kuyilapho imishini ye-ultrasonic ibiza izinkulungwane ezimbalwa kuphela. Ukwengeza, izinqubo ze-laser zisadinga ukuhlolwa okwengeziwe kwezinhlobo ezahlukene zamapulasitiki. I-Ultrasonic welding ibuye ifanele ukucubungula okuzenzakalelayo ngesivinini esikhulu nokusebenza kahle, nakuba inezinkinga zokungcoliswa komsindo nokunemba okuphansi nokubeka uphawu kune-laser welding.

Ngokwehliswa okuqhubekayo kwezintengo ze-laser nezisetshenziswa ezihambisanayo, izindleko zemishini yokushisela ipulasitiki ye-laser zingase zehlele ku-¥100,000 ($13,808) noma ngaphansi esikhathini esizayo, zihehe abasebenzisi abaningi. Njengoba ucwaningo luya lujula, ikakhulukazi emazingeni okumunca phakathi kwamapulasitiki asobala nanemibala kanye nokubunjwa ngokwezifiso, i-laser welding yamapulasitiki ingase ibone impumelelo.

Kugxilwe Kwinkundla Esekelayo Yokucubungula Ipulasitiki Ye-Laser: I-TEYU S&A I-Chiller Ekukhanyeni

Ngokukhuphuka kwezidingo zokushisela ipulasitiki yekhwalithi ephezulu kuzo zonke izimboni ezahlukahlukene, ubuchwepheshe bokushisela ipulasitiki belaser buyakhula. Ukuthuthuka okuqhubekayo kwemakethe yokushisela ipulasitiki ye-laser nakho kukhuthaza isidingo semikhiqizo esesekeli ye-laser, okungase kuholele ekwandeni kokwamukelwa kwemishini yokushisela i-laser.

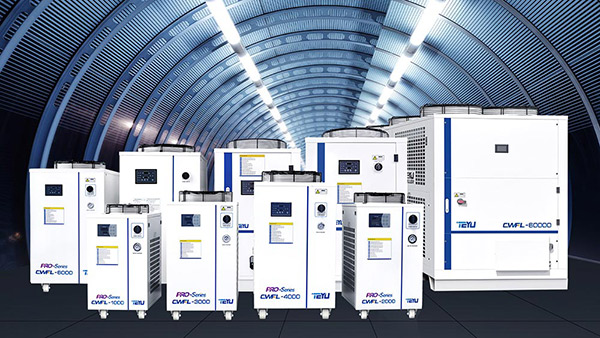

Njengengxenye ebalulekile yemishini yokushisela ipulasitiki ye-laser, amasistimu okupholisa adlala indima ebalulekile ekulawuleni izinga lokushisa. Ngesipiliyoni seminyaka engu-22 kubuchwepheshe bokupholisa nge-laser, i-Guangzhou Teyu Electromechanical Co., Ltd. (ephinde yaziwe ngokuthi i-TEYU S&A Chiller) ithuthukise uhla lwama -chiller ezimbonini afanele izinhlobo eziningi zasekhaya nezamazwe ngamazwe ze-fiber laser, i-UV laser, imishini ye-laser ye-CO2, namathuluzi omshini we-CNC. Lawa ma-chiller amboza cishe zonke izinhlobo ze-laser kanye nobubanzi bamandla amakhulu, futhi anesabelo esiqinile semakethe emkhakheni wokushisela ipulasitiki.

Kulo mkhakha, ama-chiller ezimboni e-TEYU S&A ahambisana kakhulu nemishini yesimanje yokushisela i-laser yesimanje. Isibonelo, i-TEYU S&A i-industrial chiller CW-5200 iletha ukuqina okunembile kwezinga lokushisa okungu-±0.3℃, isebenza ngamandla we-dual-frequency 220V 50/60Hz, futhi isekela zombili izindlela zokulawula izinga lokushisa ezingaguquki nezihlakaniphile. Ngezici ezifana nomthamo wokupholisa ozinzile, idizayini eco-friendly, impilo yesevisi ende, nokunemba okuphezulu, iqinisekisa ukuthi imishini yokushisela ipulasitiki ye-laser igcina izinga lokushisa elilungile lokusebenza.

Njengoba ukucubungula nge-laser—ikakhulukazi i-laser plastic welding—kuqhubeka kukhula ezinhlelweni zemakethe kanye nesidingo sokukhuphuka kwamandla aphezulu, ama-chiller ezimboni azoba utshalomali olubalulekile kubasebenzisi abaningi.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.