Ultrasonic vuam yog txoj kev mus rau ntau yam khoom yas hauv electronics, tsheb, khoom ua si, thiab cov khoom siv. Lub caij no, laser vuam tau txais kev pom zoo, muab cov txiaj ntsig tshwj xeeb. Raws li laser yas vuam txuas ntxiv loj hlob hauv kev lag luam daim ntawv thov thiab kev thov rau lub zog siab dua, cov tshuab chillers yuav dhau los ua kev nqis peev tseem ceeb rau ntau tus neeg siv.

Yuav Ua Li Cas Laser Yas Ua Lag Luam Ua Lag Luam Ua Lag Luam Tshiab?

Yas, yog ib qho ntawm tib neeg txoj kev hloov pauv ntau tshaj plaws, tam sim no yog ib qho tseem ceeb ntawm ntau txhiab qhov chaw, los ntawm kev ntim khoom mus rau hluav taws xob, tsheb, kev kho mob, thiab lwm yam. Nrog nws cov versatility, yas tuaj yeem raug cais raws li nruj lossis hloov tau thiab yog molded los ntawm cov txheej txheem xws li extrusion, tshuab molding, thiab txhaj tshuaj molding. Qee cov khoom tau npaj ua tiav hauv ib kauj ruam, thaum lwm tus xav tau kev kho kom zoo ntxiv kom tau raws li cov khoom siv kawg.

Ua raws li qhov xav tau loj hlob rau kev ua cov yas: Lub luag haujlwm ntawm Laser Vuam

Ntau qhov chaw yas tuaj yeem sib dhos ncaj qha tom qab molding. Txawm li cas los xij, cov khoom lag luam nyuaj feem ntau xav tau cov khoom siv yas los hloov kho lossis koom nrog lwm cov ntaub ntawv. Vim muaj ntau hom yas, xaiv txoj kev ua thiab cov cuab yeej siv tau zoo-tsim rau txhua yam khoom yas-yog qhov tseem ceeb.

Tam sim no, feem ntau cov txheej txheem yas cia siab rau kev siv tshuab, suav nrog sawing, shearing, drilling, sib tsoo, polishing, thiab threading. Feem ntau cov khoom siv yas, xws li PP, ABS, PET, PVC, thiab acrylic, feem ntau yog txiav nrog cov tshuab pom hniav, uas yog nyob ntawm kev ua haujlwm ntawm phau ntawv. Qhov no feem ntau ua rau muaj teeb meem nrog precision, siab tsis xws luag, thiab qhov xav tau rau kev ua tiav theem nrab kom tshem tawm burrs.

Rau drilling, mechanical drills yog feem ntau siv rau cov khoom yas. Vim lub siab nyiam ntawm cov yas polymers raug puas los ntawm cov khoom siv hlau, cov tshuab drilling yog qhov nrawm tab sis feem ntau ua cov khib nyiab yas thiab burrs raws cov npoo. Txawm hais tias cov teeb meem no, cov tshuab drilling tseem yog txoj kev paub tab thiab nrov tshaj plaws rau cov khoom yas.

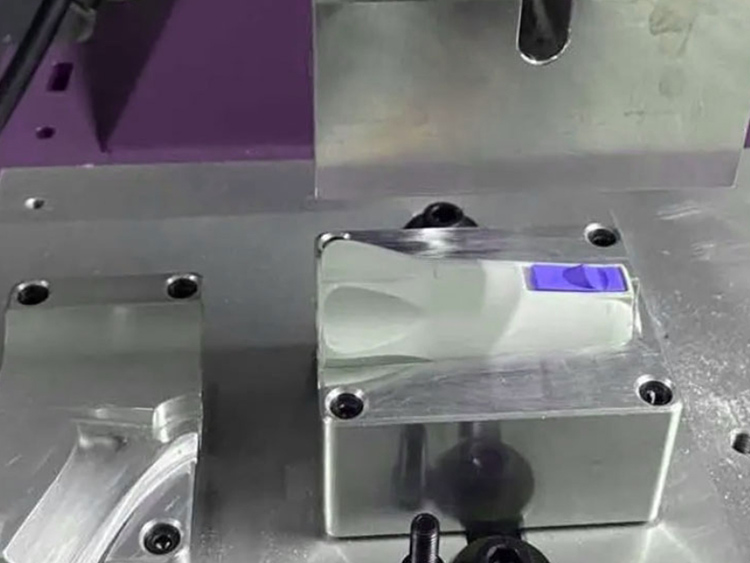

Cia peb saib ze dua ntawm cov yas vuam thev naus laus zis. Yas yog kub-rhiab heev, yog li welding nws feem ntau cuam tshuam nrog melting los yog softening mus koom qhov chaw. Cov txheej txheem zoo li cov phaj kub welding haum cov khoom yas loj nrog cov chaw sib cuag.

(Ultrasonic Vuam)

Ultrasonic vuam yog txoj kev mus rau ntau yam khoom yas hauv kev lag luam xws li hluav taws xob, tsheb, khoom ua si, tshuaj pleev ib ce, thiab cov khoom siv. Txoj kev no siv cov tshuab hluav taws xob ntau zaus los ua kom muaj cua sov tam sim thiab cov khoom siv yas.

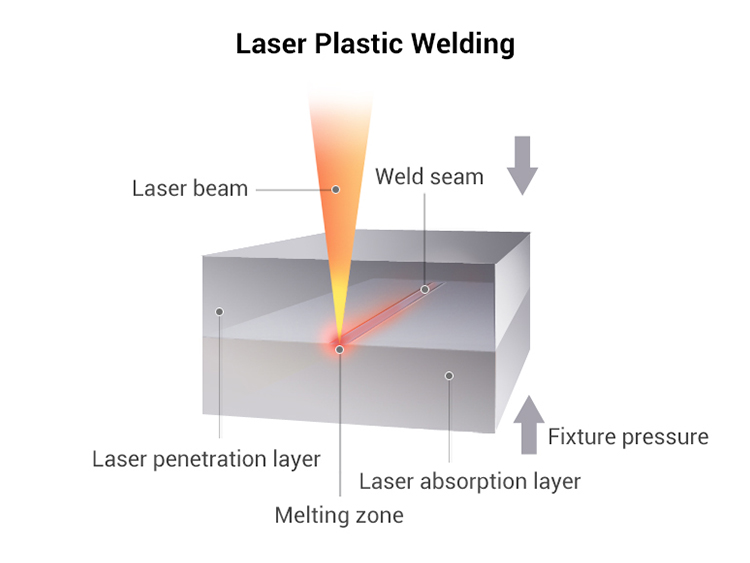

Lub caij no, laser vuam - ib txoj kev tshiab - tau txais kev mloog. Los ntawm kev siv laser-tsim cua sov precisely ntawm qhov sib koom ua ke, laser vuam muaj cov txiaj ntsig tshwj xeeb. Puas muaj peev xwm tawg tau laser coj mus rau kev ua cov yas?

Tshawb nrhiav qhov muaj peev xwm ua tiav Laser hauv kev tsim cov yas: Cov khoom siv qis dua tuaj yeem yog qhov zoo

Laser npav yog twb tau siv dav hauv kev ua cov yas, tshwj xeeb tshaj yog rau cov ntawv sau cov khoom xws li cables, chargers, thiab cov khoom siv casings. UV laser npav tshuab yog cov paub tab thiab tsim nyog rau kev ntxiv cov cim npe lossis cov khoom lag luam ntawm cov khoom yas.

Rau kev txiav thiab drilling, txawm li cas los xij, kev ua laser ntsib teeb meem. Lub tshav kub rhiab heev ntawm cov yas tuaj yeem ua rau yaj lossis hlawv, ua rau nws nyuaj rau kev ua kom huv huv tsis muaj qhov tsaus ntuj lossis scorched npoo. Txawm hais tias cov yas pob tshab tseem tsis tuaj yeem txiav nrog lasers, cov yas dub muaj peev xwm nrog cov khoom siv hluav taws xob siab, lub zog hluav taws xob siab. Raws li kev siv tshuab laser nce qib-tshwj xeeb tshaj yog nyob rau hauv ultrashort mem tes lasers-txiav yas yuav ua tau zoo dua.

Raws li tau hais tseg, laser vuam ntawm cov yas yog cov thev naus laus zis tshiab uas muab cov txiaj ntsig zoo xws li kev ceev ceev, siab precision, muaj zog ntsaws ruaj ruaj, cov txheej txheem tsis muaj kuab paug, thiab cov khoom sib txuas, tsim nyog rau kev siv hauv tsheb, khoom siv kho mob, thiab cov khoom siv hluav taws xob. Txawm li cas los xij, txawm tias nyob hauv kev ua lag luam rau ntau xyoo, laser yas vuam tseem yog ib qho niche, feem ntau yog cov khoom siv ultrasonic. Tus nqi yog ib qhov teeb meem, nrog laser yas vuam tshuab raug nqi kaum tawm txhiab yuan, thaum lub tshuab ultrasonic nqi tsuas yog ob peb txhiab. Tsis tas li ntawd, cov txheej txheem laser tseem xav tau kev tshawb nrhiav ntxiv rau ntau hom yas. Ultrasonic vuam kuj yog tsim rau automated ua nrog kev kub ceev thiab efficiency, txawm hais tias nws muaj suab nrov muaj kuab paug teeb meem thiab qis precision thiab sealing dua laser vuam.

Nrog kev txo qis hauv laser thiab cov khoom siv cuam tshuam nrog tus nqi, tus nqi ntawm cov tshuab yas laser vuam tej zaum yuav poob rau ¥ 100,000 ($ 13,808) lossis tsawg dua yav tom ntej, nyiam cov neeg siv ntau dua. Raws li kev tshawb fawb tob zuj zus, tshwj xeeb tshaj yog rau hauv kev nqus ntawm cov pob tshab thiab cov xim yas thiab cov kev cai shaping, laser vuam rau cov yas yuav pom kev tawg.

Tsom ntsoov rau kev txhawb nqa ntawm Laser Yas Txheej Txheem: TEYU S&A Chiller hauv qhov tsom teeb

Nrog kev xav tau nce siab rau cov yas vuam zoo thoob plaws ntau qhov kev lag luam, laser yas vuam tshuab tau txais qhov chaw. Kev txhim kho txuas ntxiv ntawm laser yas vuam kev lag luam kuj txhawb kev thov rau cov khoom siv laser, uas ua rau muaj kev nce siab hauv kev siv cov khoom siv laser vuam.

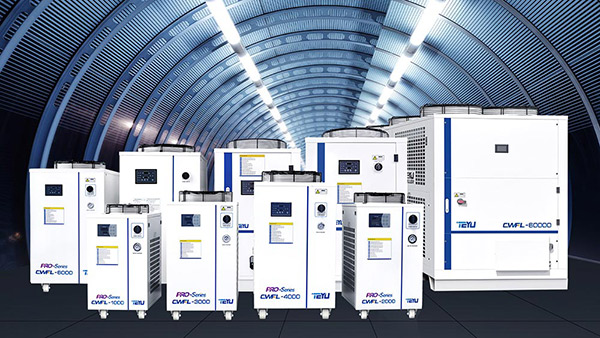

Raws li qhov tseem ceeb ntawm cov khoom siv laser yas vuam, cov tshuab cua txias ua lub luag haujlwm tseem ceeb hauv kev tswj qhov kub thiab txias. Nrog 22 xyoo ntawm kev paub nyob rau hauv laser txias tshuab, Guangzhou Teyu Electromechanical Co., Ltd. (tseem hu ua TEYU S&A Chiller) tau tsim ib tug ntau yam ntawm industrial chillers haum rau feem ntau domestic thiab thoob ntiaj teb hom fiber ntau laser, UV laser, CO2 laser khoom, thiab CNC tshuab cuab yeej. Cov chillers no npog yuav luag txhua hom laser thiab lub zog loj, thiab lawv tuav cov lag luam muaj zog hauv cov yas vuam sector.

Nyob rau hauv daim teb no, TEYU S&A industrial chillers tau sib xws nrog cov khoom siv niaj hnub yas laser vuam. Piv txwv li, TEYU S&A industrial chiller CW-5200 muab qhov ntsuas kub ruaj khov ntawm ± 0.3 ℃, ua haujlwm ntawm dual-frequency 220V 50 / 60Hz lub zog, thiab txhawb nqa ob qho tib si tas li thiab ntse ntsuas kub hom. Nrog cov yam ntxwv zoo li lub peev xwm txias txias, eco-phooj ywg tsim, kev pab lub neej ntev, thiab siab precision, nws ua kom lub laser yas vuam tshuab tswj kev ua haujlwm zoo.

Raws li kev ua laser-tshwj xeeb tshaj yog laser yas vuam-txuas ntxiv rau hauv kev lag luam daim ntawv thov thiab kev thov rau lub zog siab dua, cov tshuab chillers yuav dhau los ua kev nqis peev tseem ceeb rau ntau tus neeg siv.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.