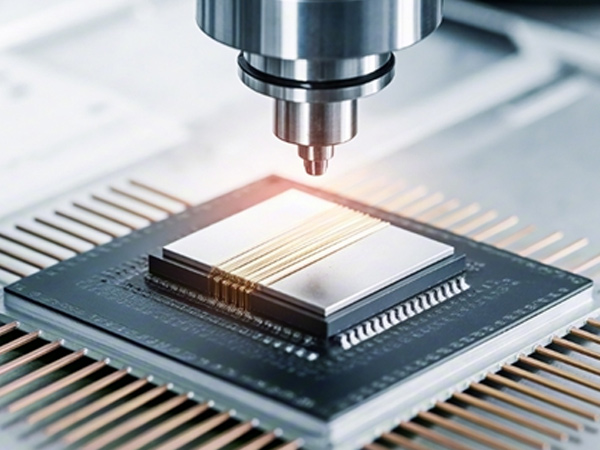

Matsalolin ƙarfe a cikin sarrafa semiconductor, kamar electromigration da haɓaka juriyar lamba, na iya lalata aikin guntu da aminci. Wadannan matsalolin sun fi haifar da sauyin yanayin zafi da canje-canjen ƙananan tsarin. Magani sun haɗa da madaidaicin sarrafa zafin jiki ta amfani da chillers masana'antu, ingantattun hanyoyin tuntuɓar juna, da amfani da kayan haɓaka.

Batutumomin ƙarfe a cikin sarrafa semiconduction da yadda za a warware su

Ƙarfafawa mataki ne mai mahimmanci a sarrafa na'ura mai kwakwalwa, wanda ya haɗa da samar da haɗin gwiwar ƙarfe kamar jan karfe ko aluminum. Duk da haka, al'amurran da suka shafi ƙarfe-musamman lantarki na lantarki da haɓaka juriya na lamba-suna haifar da ƙalubale ga aiki da amincin haɗaɗɗun da'irori.

Dalilan Matsalolin Ƙarfafawa

Matsalolin ƙarfe na ƙarfe suna farawa da farko ta yanayin yanayin zafi mara kyau da sauye-sauyen ƙananan ƙananan abubuwa yayin ƙirƙira:

1. Yawan zafin jiki: A lokacin zafi mai zafi, haɗin haɗin ƙarfe na iya fuskantar haɓakar lantarki ko haɓakar hatsi mai yawa. Waɗannan canje-canjen ƙananan tsarin suna lalata kaddarorin lantarki kuma suna rage amincin haɗin gwiwa.

2. Rashin isasshen zafin jiki: Idan yawan zafin jiki ya yi ƙasa sosai, ba za a iya inganta juriya na lamba tsakanin karfe da silicon ba, wanda ke haifar da mummunar watsawa na yanzu, ƙara yawan amfani da wutar lantarki, da rashin daidaituwa na tsarin.

Tasiri kan Ayyukan Chip

Haɗuwa da tasirin wutar lantarki, haɓakar hatsi, da haɓaka juriya na lamba na iya lalata aikin guntu sosai. Alamomin sun haɗa da saurin watsa sigina, kurakuran dabaru, da babban haɗarin gazawar aiki. Wannan a ƙarshe yana haifar da ƙarin farashi na kulawa da rage yanayin rayuwar samfur.

Maganin Matsalolin Ƙarfafa Ƙarfafawa

1. Haɓaka Kula da Zazzabi: Aiwatar da madaidaicin kulawar thermal, kamar yin amfani da chillers na masana'antu na masana'antu , yana taimakawa kula da yanayin yanayin daidaitacce. Tsayayyen sanyi yana rage haɗarin lantarki kuma yana haɓaka juriya na ƙarfe-silicon, haɓaka aikin guntu da aminci.

2. Haɓaka Tsari: Daidaita kayan, kauri, da hanyoyin sanyawa na layin lamba zai iya taimakawa wajen rage juriya na lamba. Dabaru irin su tsarin multilayer ko doping tare da takamaiman abubuwa suna haɓaka kwarara da kwanciyar hankali na yanzu.

3. Zaɓin Material: Yin amfani da karafa tare da babban juriya ga electromigration, kamar gawawwakin jan ƙarfe, da kayan haɗin kai sosai irin su doped polysilicon ko silicides na ƙarfe, na iya ƙara rage girman juriya na lamba kuma tabbatar da aiki na dogon lokaci.

Kammalawa

Za a iya rage al'amurran da suka shafi ƙarfe a cikin sarrafa semiconductor yadda ya kamata ta hanyar sarrafa zafin jiki na ci gaba, ingantaccen ƙirƙira lamba, da zaɓin kayan dabaru. Waɗannan mafita suna da mahimmanci don kiyaye aikin guntu, tsawaita rayuwar samfur, da tabbatar da amincin na'urorin semiconductor.

Muna nan a gare ku lokacin da kuke buƙatar mu.

Da fatan za a cika fom ɗin don tuntuɓar mu, kuma za mu yi farin cikin taimaka muku.