Litaba tsa metallization ts'ebetsong ea semiconductor, tse kang electromigration le ho eketseha ha khanyetso, li ka senya ts'ebetso ea chip le ho tšepahala. Mathata ana a bakoa haholo-holo ke ho fetoha ha mocheso le liphetoho tsa microstructural. Litharollo li kenyelletsa taolo e nepahetseng ea mocheso o sebelisa li-chiller tsa indasteri, mekhoa e ntlafalitsoeng ea ho ikopanya le ts'ebeliso ea lisebelisoa tse tsoetseng pele.

Mathata a Metallization ho Semiconductor Processing le Mokhoa oa ho a Rarolla

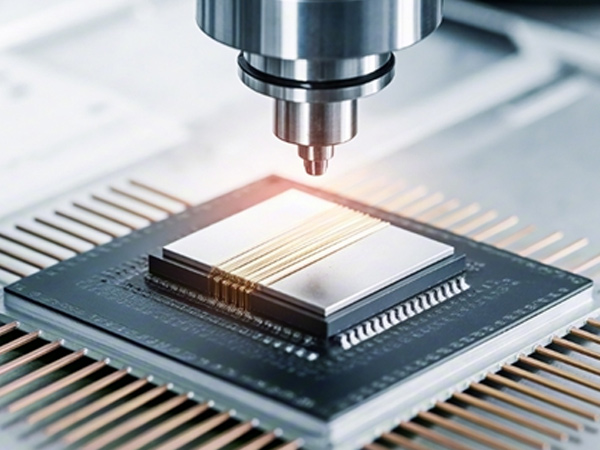

Metallization ke mohato oa bohlokoa ts'ebetsong ea semiconductor, e kenyelletsang ho thehoa ha likhokahano tsa tšepe tse kang koporo kapa aluminium. Leha ho le joalo, litaba tsa metallization-haholo-holo electromigration le ho eketseha ha khanyetso ea ho kopana-li baka mathata a maholo mosebetsing le ho tšepahala ha lipotoloho tse kopantsoeng.

Lisosa tsa Mathata a Metallization

Mathata a tšepe a bakoa haholo-holo ke maemo a sa tloaelehang a mocheso le liphetoho tse nyenyane nakong ea ho etsoa:

1. Mocheso o feteletseng: Nakong ea annealing e phahameng ea mocheso, likhokahano tsa tšepe li ka ba le electromigration kapa kholo e feteletseng ea lijo-thollo. Liphetoho tsena tsa microstructural li senya thepa ea motlakase le ho fokotsa botšepehi ba likhokahano.

2. Mocheso o sa lekaneng: Haeba mocheso o le tlase haholo, khanyetso ea ho kopana pakeng tsa tšepe le silicon e ke ke ea ntlafatsoa, e lebisang ho fetisoe e mpe ea hona joale, ho eketseha ha matla a matla, le ho se tsitse ha tsamaiso.

Tšusumetso ho Ts'ebetso ea Chip

Liphello tse kopantsoeng tsa ho falla ha motlakase, kholo ea lijo-thollo, le ho eketseha ha khanyetso ea ho kopana ho ka senya ts'ebetso ea chip haholo. Matšoao a kenyelletsa phetiso ea mats'oao butle, liphoso tsa mohopolo, le kotsi e kholo ea ho hloleha ha ts'ebetso. Qetellong sena se fella ka ho eketseha ha litšenyehelo tsa tlhokomelo le ho fokotsa nako ea bophelo ba sehlahisoa.

Tharollo ea Mathata a Metallization

1. Ntlafatso ea Taolo ea Mocheso: Ho kenya ts'ebetsong tsamaiso e nepahetseng ea mocheso, joalo ka ho sebelisa li-water chillers tsa boemo ba indasteri , ho thusa ho boloka mocheso o tsitsitseng oa ts'ebetso. Pholiso e tsitsitseng e fokotsa kotsi ea ho falla ha motlakase 'me e ntlafatsa khanyetso ea tšepe-silicone, e ntlafatsa ts'ebetso ea chip le ho tšepahala.

2. Ntlafatso ea Ts'ebetso: Ho fetola lisebelisoa, botenya, le mekhoa ea ho beha sebaka sa ho ikopanya ho ka thusa ho fokotsa khanyetso ea ho ikopanya. Mekhoa e kang mehaho ea li-multilayer kapa doping e nang le likarolo tse itseng e ntlafatsa phallo ea hona joale le botsitso.

3. Khetho ea Lintho: Ho sebelisa litšepe tse nang le khanyetso e phahameng ea electromigration, joaloka li-alloys tsa koporo, le lisebelisoa tsa ho kopana tse tsamaisang haholo tse kang doped polysilicon kapa li-silicone tsa tšepe, li ka fokotsa ho hanyetsa ho kopana le ho netefatsa ts'ebetso ea nako e telele.

Qetello

Litaba tsa metallization ts'ebetsong ea semiconductor li ka fokotsoa ka mokhoa o atlehileng ka taolo e tsoetseng pele ea mocheso, mokhoa o ntlafalitsoeng oa ho ikopanya le khetho ea lisebelisoa tsa maano. Litharollo tsena li bohlokoa bakeng sa ho boloka ts'ebetso ea chip, ho lelefatsa bophelo ba sehlahisoa, le ho netefatsa ho ts'epahala ha lisebelisoa tsa semiconductor.

Re mona bakeng sa hau ha o re hloka.

Ka kopo tlatsa foromo ho ikopanya le rona, 'me re tla thabela ho u thusa.