Metallization nyaya mu semiconductor kugadzirisa, senge electromigration uye kuwedzera kuonana kuramba, zvinogona kukanganisa chip performance uye kuvimbika. Aya matambudziko anonyanya kukonzerwa nekushanduka kwekushisa uye shanduko ye microstructural. Mhinduro dzinosanganisira chaiyo tembiricha yekudzora uchishandisa maindasitiri kutonhora, yakagadziridzwa maitiro ekusangana, uye kushandiswa kwezvinhu zvepamberi.

Matambudziko eMetallization muSemiconductor Processing uye Magadzirirwo Azvo

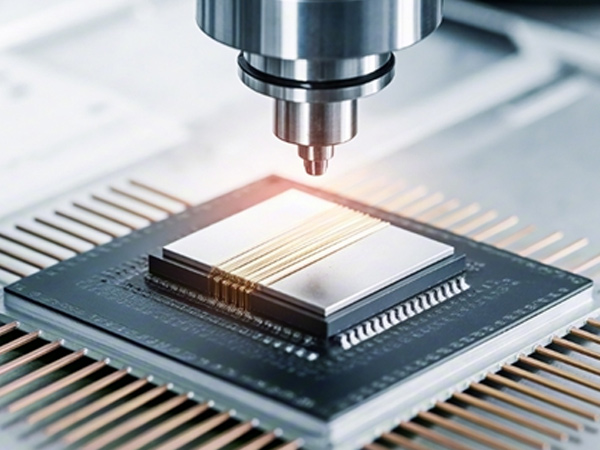

Metallization inhanho yakakosha mukugadzirisa semiconductor, inosanganisira kuumbwa kwesimbi inobatana semhangura kana aluminium. Nekudaro, nyaya dzesimbi - kunyanya electromigration uye kuwedzera kupikisa kuramba - zvinounza matambudziko makuru pakuita uye kuvimbika kwemaseketi akabatanidzwa.

Zvinokonzera Metallization Matambudziko

Matambudziko eMetallization anonyanya kukonzerwa nekusajaira tembiricha mamiriro uye microstructural shanduko panguva yekugadzira:

1. Tembiricha yakawandisa: Munguva yekupisa kwepamusoro-tembiricha, masimbi anobatana anogona kuona electromigration kana kukura kwezviyo zvakanyanya. Idzi shanduko dze microstructural dzinokanganisa zvinhu zvemagetsi uye kuderedza kuvimbika kwekubatanidza.

2. Kusakwana kwekushisa: Kana kutonhora kwakanyanya kuderera, kupikisa kwekubatana pakati pesimbi nesilicon hakugoni kugadziriswa, zvichiita kuti urombo husina hutachiwana huripo, huwedzere kushandiswa kwesimba, uye kusagadzikana kwehurongwa.

Impact pane Chip Performance

Izvo zvakasanganiswa mhedzisiro ye electromigration, kukura kwezviyo, uye nekuwedzera kuonana kuramba kunogona kukanganisa zvakanyanya chip performance. Zviratidzo zvinosanganisira kunonoka kutapurirana chiratidzo, zvikanganiso zvepfungwa, uye njodzi yakanyanya yekutadza kushanda. Izvi zvinopedzisira zvakonzera kuwedzera kwemitengo yekugadzirisa uye kuderedzwa kwehupenyu hwechigadzirwa.

Mhinduro dzeMetallization Matambudziko

1. Temperature Control Optimization: Implementing precise thermal management, sekushandisa industrial-grade water chillers , inobatsira kuchengetedza kuwirirana kwemaitiro ekupisa. Kutonhora kwakadzikama kunoderedza njodzi yekufambiswa kwemagetsi uye inokwidziridza simbi-silicon yekubata kuramba, inosimudzira chip performance uye kuvimbika.

2. Kuvandudza Maitiro: Kugadzirisa zvinhu, ukobvu, uye deposition nzira dzeiyo yekusangana layer inogona kubatsira kuderedza kusangana kushomeka. Matekiniki akadai seakawanda magadzirirwo kana doping ane chaiwo maelement anovandudza kuyerera kwezvino uye kugadzikana.

3. Kusarudzwa Kwezvinhu: Kushandisa simbi dzine kupikisa kukuru kwe electromigration, kufanana nemhangura yemhangura, uye zvakanyanya conductive zvinosangana nezvinhu zvakadai sedoped polysilicon kana simbi silicides, zvinogona kuwedzera kuderedza kusangana kwekupikisa uye kuvimbisa kushanda kwenguva refu.

Mhedziso

Metallization nyaya mu semiconductor kugadzirisa inogona kudzikiswa zvine mutsindo kuburikidza nepamusoro tembiricha yekudzora, yakagadziridzwa yekugadzira yekugadzira, uye sarudzo yemhando yezvinhu. Mhinduro idzi dzakakosha pakuchengetedza chip performance, kuwedzera hupenyu hwechigadzirwa, uye kuve nechokwadi chekuvimbika kwemidziyo yesemiconductor.

Tiripo nokuda kwenyu kana muchitida.

Ndapota zadza fomu kuti ubate nesu, uye isu tichafara kukubatsira.