Nkhani za zitsulo pakukonza semiconductor, monga electromigration ndi kuchuluka kwa kukhudzana, zimatha kusokoneza magwiridwe antchito a chip ndi kudalirika. Mavutowa amayamba makamaka chifukwa cha kusinthasintha kwa kutentha ndi kusintha kwa microstructural. Zothetserazo zikuphatikiza kuwongolera kutentha kolondola pogwiritsa ntchito zozizira zamafakitale, njira zolumikizirana bwino, komanso kugwiritsa ntchito zida zapamwamba.

Nkhani za Metallization mu Semiconductor Processing ndi Momwe Mungathetsere

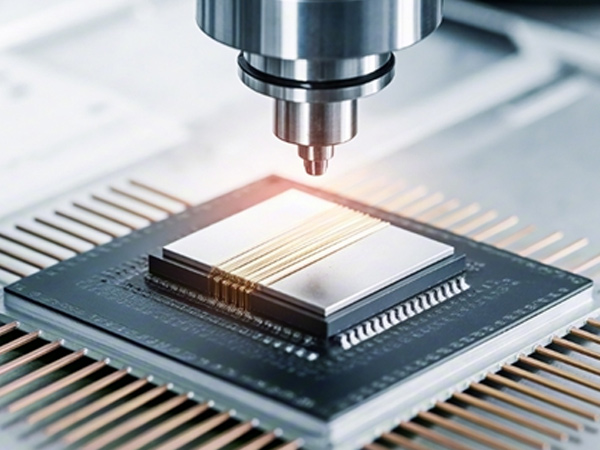

Metallization ndi gawo lofunika kwambiri pakukonza semiconductor, kuphatikiza kupanga zolumikizira zitsulo monga mkuwa kapena aluminiyamu. Komabe, zovuta zazitsulo - makamaka electromigration ndi kuwonjezereka kwa kukhudzana ndi kukhudzana-zimabweretsa zovuta zazikulu pakugwira ntchito ndi kudalirika kwa mabwalo ophatikizika.

Zomwe Zimayambitsa Mavuto a Metallization

Mavuto azitsulo amayamba chifukwa cha kutentha kwachilendo komanso kusintha kwa microstructural panthawi yopanga:

1. Kutentha kwakukulu: Panthawi yotentha kwambiri, zolumikizira zitsulo zimatha kukhala ndi electromigration kapena kukula kwambewu. Kusintha kwa microstructural uku kumasokoneza mphamvu zamagetsi ndikuchepetsa kudalirika kwa interconnect.

2. Kutentha kosakwanira: Ngati kutentha kuli kochepa kwambiri, kukana kukhudzana pakati pa zitsulo ndi silicon sikungatheke, zomwe zimapangitsa kuti pakhale kusayenda bwino kwamakono, kuwonjezereka kwa mphamvu zamagetsi, ndi kusakhazikika kwadongosolo.

Impact pa Chip Performance

Zotsatira zophatikizana za electromigration, kukula kwa tirigu, ndi kuwonjezereka kwa kukhudzana kungawononge kwambiri ntchito ya chip. Zizindikiro zimaphatikizira kufalitsa ma siginecha pang'onopang'ono, zolakwika zamalingaliro, komanso chiwopsezo chachikulu cha kulephera kwa ntchito. Izi pamapeto pake zimabweretsa kukwera mtengo kwa kukonza ndikuchepetsa moyo wazinthu.

Zothetsera Mavuto a Metallization

1. Kukonzekera kwa Kutentha kwa Kutentha: Kugwiritsa ntchito kasamalidwe kabwino ka kutentha, monga kugwiritsa ntchito mafakitale-grade water chillers , kumathandiza kusunga kutentha kosasinthasintha. Kuzizira kokhazikika kumachepetsa chiopsezo cha electromigration ndikukulitsa kukana kwachitsulo-silicon, kupititsa patsogolo magwiridwe antchito a chip ndi kudalirika.

2. Kupititsa patsogolo Njira: Kusintha zipangizo, makulidwe, ndi njira zoyikapo za kusanjikizana kungathandize kuchepetsa kukana. Njira monga zopangira ma multilayer kapena doping yokhala ndi zinthu zinazake zimathandizira kuyenda komanso kukhazikika.

3. Kusankha Zinthu: Kugwiritsa ntchito zitsulo zokhala ndi kukana kwambiri kwa electromigration, monga ma aloyi amkuwa, ndi zipangizo zogwiritsira ntchito kwambiri monga doped polysilicon kapena zitsulo zachitsulo, zimatha kuchepetsa kukana kukhudzana ndi kuonetsetsa kuti ntchito yayitali.

Mapeto

Nkhani za Metallization mu semiconductor processing zitha kuchepetsedwa bwino kudzera pakuwongolera kutentha kwapamwamba, kukhathamiritsa kulumikizidwa kolumikizana, komanso kusankha zinthu mwanzeru. Mayankho awa ndi ofunikira pakusunga magwiridwe antchito a chip, kukulitsa moyo wazinthu, ndikuwonetsetsa kudalirika kwa zida za semiconductor.

Tabwera chifukwa cha inu mukadzatifuna.

Chonde lembani fomu yolumikizana nafe, ndipo tidzakhala okondwa kukuthandizani.