Metallization issues in semiconductor processing, such as electromigration and increased contact resistance, can degrade chip performance and reliability. These problems are mainly caused by temperature fluctuations and microstructural changes. Solutions include precise temperature control using industrial chillers, improved contact processes, and the use of advanced materials.

Metallization Issues in Semiconductor Processing and How to Solve Them

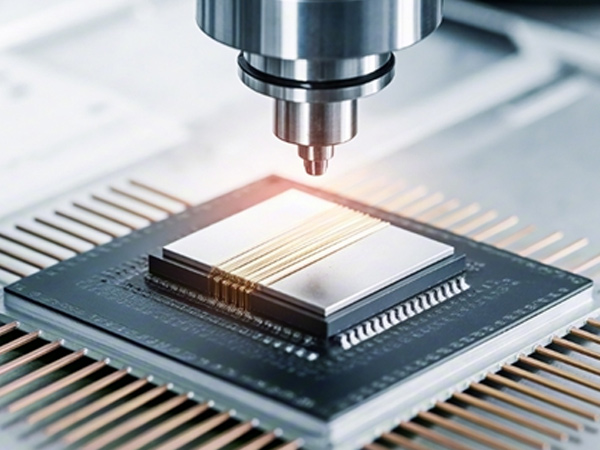

Metallization is a critical step in semiconductor processing, involving the formation of metal interconnects such as copper or aluminum. However, metallization issues—particularly electromigration and increased contact resistance—pose significant challenges to the performance and reliability of integrated circuits.

Causes of Metallization Issues

Metallization problems are primarily triggered by abnormal temperature conditions and microstructural changes during fabrication:

1. Excessive temperature: During high-temperature annealing, metal interconnects can experience electromigration or excessive grain growth. These microstructural changes compromise the electrical properties and reduce interconnect reliability.

2. Insufficient temperature: If the temperature is too low, the contact resistance between metal and silicon cannot be optimized, leading to poor current transmission, increased power consumption, and system instability.

Impact on Chip Performance

The combined effects of electromigration, grain growth, and increased contact resistance can significantly degrade chip performance. Symptoms include slower signal transmission, logic errors, and a higher risk of operational failure. This ultimately results in increased maintenance costs and reduced product life cycles.

Solutions to Metallization Problems

1. Temperature Control Optimization: Implementing precise thermal management, such as using industrial-grade water chillers, helps maintain consistent process temperatures. Stable cooling reduces the risk of electromigration and optimizes metal-silicon contact resistance, enhancing chip performance and reliability.

2. Process Improvement: Adjusting the materials, thickness, and deposition methods of the contact layer can help reduce contact resistance. Techniques such as multilayer structures or doping with specific elements improve current flow and stability.

3. Material Selection: Using metals with high resistance to electromigration, like copper alloys, and highly conductive contact materials such as doped polysilicon or metal silicides, can further minimize contact resistance and ensure long-term performance.

Conclusion

Metallization issues in semiconductor processing can be effectively mitigated through advanced temperature control, optimized contact fabrication, and strategic material selection. These solutions are essential for maintaining chip performance, extending product lifespan, and ensuring the reliability of semiconductor devices.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.