Izinkinga ze-Metallization ekucubungulweni kwe-semiconductor, njengokuhamba kwe-electromigration kanye nokwanda kokumelana nokuxhumana, kungehlisa ukusebenza kwe-chip nokuthembeka. Lezi zinkinga zibangelwa kakhulu ukushintsha kwezinga lokushisa kanye nezinguquko ze-microstructural. Izixazululo zihlanganisa ukulawulwa kwezinga lokushisa okunembile kusetshenziswa ama-chiller embonini, izinqubo ezithuthukisiwe zokuxhumana, kanye nokusetshenziswa kwezinto ezithuthukisiwe.

Izinkinga ze-Metallization ku-Semiconductor Processing kanye nokuthi Zizixazululwa Kanjani

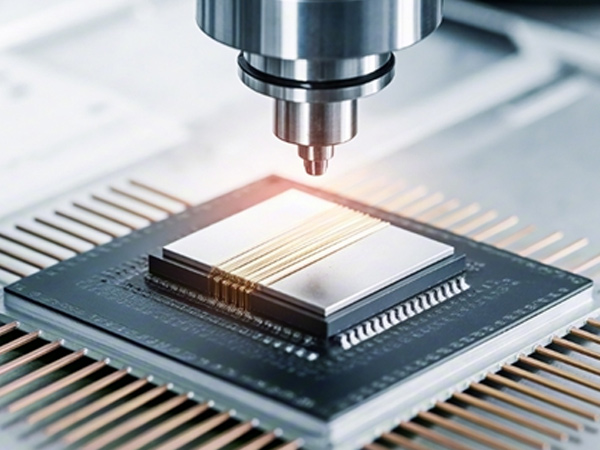

Ukwenziwa kwensimbi kuyisinyathelo esibalulekile ekucutshungulweni kwe-semiconductor, okubandakanya ukwakheka kwezixhumi zensimbi njengethusi noma i-aluminium. Kodwa-ke, izinkinga ze-metallization-ikakhulukazi i-electromigration kanye nokwanda kokumelana nokuxhumana-kubangela izinselele ezinkulu ekusebenzeni nokuthembeka kwamasekhethi ahlanganisiwe.

Izimbangela Zezinkinga Ze-Metallization

Izinkinga ze-Metallization zibangelwa ikakhulukazi izimo zokushisa ezingavamile kanye nezinguquko ze-microstructural ngesikhathi sokwenziwa:

1. Izinga lokushisa elidlulele: Ngesikhathi sokushisa okuphezulu kwe-anneal, izixhumi zensimbi zingaba ne-electromigration noma ukukhula okusanhlamvu okweqile. Lezi zinguquko ze-microstructural ziphazamisa izakhiwo zikagesi futhi zinciphisa ukwethembeka kokuxhuma.

2. Izinga lokushisa elinganele: Uma izinga lokushisa liphansi kakhulu, ukumelana nokuxhumana phakathi kwensimbi ne-silicon akukwazi ukwenziwa ngcono, okuholela ekudluliselweni okubi kwamanje, ukusetshenziswa kwamandla okwandayo, nokungaqini kwesistimu.

Umthelela Ekusebenzeni Kwe-Chip

Imiphumela ehlanganisiwe yokufuduka kwe-electromigration, ukukhula okusanhlamvu, nokwanda kokumelana nokuxhumana kungathunaza kakhulu ukusebenza kwe-chip. Izimpawu zifaka phakathi ukudluliswa kwesignali okuhamba kancane, amaphutha engqondo, kanye nengozi ephezulu yokwehluleka ukusebenza. Lokhu ekugcineni kuphumela ekwenyukeni kwezindleko zokunakekela kanye nokuncipha kwemijikelezo yokuphila komkhiqizo.

Izixazululo zezinkinga ze-Metallization

1. Ukuthuthukisa Ukulawulwa Kwezinga Lokushisa: Ukusebenzisa ukuphatha okushisayo okunembayo, okufana nokusebenzisa ama-chiller amanzi ebanga lezimboni , kusiza ukugcina amazinga okushisa enqubo engashintshi. Ukupholisa okuzinzile kunciphisa ubungozi bokufuduka kwe-electromigration futhi kukhulisa ukumelana nokuxhumana kwe-metal-silicon, kuthuthukisa ukusebenza kwe-chip nokuthembeka.

2. Ukuthuthukiswa Kwenqubo: Ukulungisa izinto, ukujiya, nezindlela zokubeka zesendlalelo sokuxhumana kungasiza ekunciphiseni ukumelana nokuxhumana. Amasu afana nezakhiwo zezendlalelo eziningi noma i-doping enezici ezithile athuthukisa ukugeleza kwamanje nokuzinza.

3. Ukukhethwa Kwezinto: Ukusebenzisa izinsimbi ezinokumelana okuphezulu kwe-electromigration, njengama-alloys ethusi, kanye nezinto zokuxhumana ezihamba phambili ezifana ne-doped polysilicon noma izinsimbi zensimbi, kungaqhubeka nokunciphisa ukumelana nokuxhumana nokuqinisekisa ukusebenza kwesikhathi eside.

Isiphetho

Izinkinga ze-metallization ekucubungulweni kwe-semiconductor zingancishiswa ngempumelelo ngokulawulwa kwezinga lokushisa okuthuthukisiwe, ukwenziwa okuthuthukisiwe kokuxhumana, nokukhethwa kwezinto zamasu. Lezi zixazululo zibalulekile ekugcineni ukusebenza kwe-chip, ukunweba ubude besikhathi sokuphila komkhiqizo, kanye nokuqinisekisa ukwethembeka kwamadivayisi we-semiconductor.

Sikhona ngenxa yakho uma usidinga.

Sicela ugcwalise ifomu ukuze uxhumane nathi, futhi sizokujabulela ukukusiza.