Arrimaha Metallization ee habaynta semiconductor, sida korantada iyo korodhka caabbinta xidhiidhka, waxay hoos u dhigi kartaa waxqabadka chip iyo isku halaynta. Dhibaatooyinkan waxaa inta badan sababa isbeddelka heerkulka iyo isbeddelada qaab-dhismeedka yar yar. Xalka waxaa ka mid ah xakamaynta heerkulka saxda ah iyadoo la isticmaalayo qaboojiyeyaasha warshadaha, hababka xiriirka oo la wanaajiyey, iyo isticmaalka alaabta horumarsan.

Arrimaha Metallization ee Habaynta Semiconductor iyo Sida loo Xaliyo

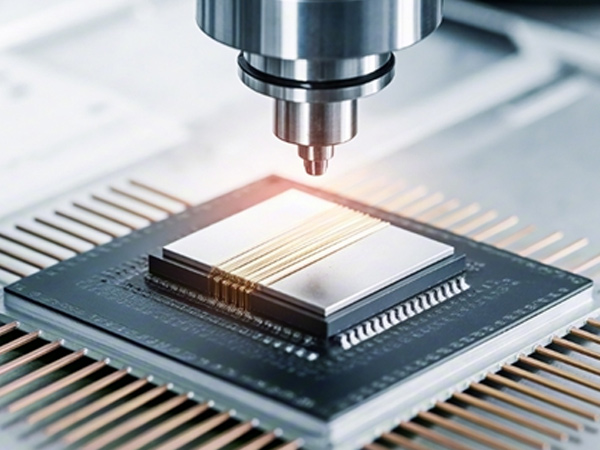

Metallization waa tallaabo muhiim u ah habaynta semiconductor, ku lug leh samaynta isku xidhka birta sida naxaasta ama aluminium. Si kastaba ha ahaatee, arrimaha birta-gaar ahaan korantada iyo kororka caabbinta xiriirka-ayaa caqabado weyn ku ah waxqabadka iyo isku halaynta wareegyada isku dhafan.

Sababaha Arrimaha Metallization

Dhibaatooyinka biraha waxaa ugu horrayn ka dhasha xaaladaha heerkulka aan caadiga ahayn iyo isbeddellada qaab-dhismeed yar yar inta lagu jiro abuuritaanka:

1. Heerkulka xad dhaafka ah: Inta lagu jiro heerkulku sarreeyo, isku xidhka birta waxay la kulmi karaan koronto ama koror xad dhaaf ah. Isbeddelladan qaab-dhismeed-yar waxay wax u dhimaan guryaha korantada waxayna yareeyaan isku halaynta isku xidhka.

2. Heerkul aan ku filnayn: Haddii heerkulku aad u hooseeyo, iska caabbinta xidhiidhka ka dhexeeya birta iyo silikoon lama hagaajin karo, taasoo horseedaysa gudbinta hadda liidata, korodhka isticmaalka tamarta, iyo xasilloonida nidaamka.

Saamaynta Waxqabadka Chip

Saamaynta isku dhafan ee korantada, korriinka hadhuudhka, iyo korodhka caabbinta xidhiidhka ayaa si weyn hoos u dhigi kara waxqabadka chip. Calaamadaha waxaa ka mid ah gudbinta calaamadaha oo gaabis ah, khaladaadka macquulka ah, iyo khatarta sare ee fashilka shaqada. Tani waxay ugu dambeyntii keentaa kororka kharashka dayactirka iyo hoos u dhaca wareegyada nolosha alaabta.

Xalka Dhibaatooyinka Metallization

1. Hagaajinta Xakamaynta Heerkulka: Hirgelinta maaraynta kulaylka saxda ah, sida isticmaalka qaboojiyeyaasha biyaha heerka warshadaha , waxay caawisaa in la ilaaliyo heerkulka nidaamka. Qaboojinta xasiloon waxay yaraynaysaa halista koronto-guurista waxayna wanaajisaa iska caabbinta birta-silikoonka, kor u qaadida waxqabadka chip iyo isku halaynta.

2. Hagaajinta Habka: Hagaajinta alaabta, dhumucda, iyo hababka dhigista lakabka xiriirka ayaa kaa caawin kara yaraynta caabbinta xiriirka. Farsamooyinka sida qaab-dhismeedka lakabyo badan ama doping oo leh walxo gaar ah ayaa hagaajiya socodka iyo xasilloonida hadda.

3. Xulashada Qalabka: Isticmaalka biraha leh caabbinta sare ee korantada, sida aluminium naxaas ah, iyo qalabka xiriirka aadka u dhaqma sida polysilicon ama silicides birta ah, waxay sii yareyn kartaa caabbinta xiriirka waxayna hubin kartaa waxqabadka muddada dheer.

Gabagabo

Arrimaha Metallization ee habaynta semiconductor si wax ku ool ah ayaa loo yarayn karaa iyada oo loo marayo xakamaynta heerkulka sare, samaynta xidhiidhka la wanaajiyey, iyo xulashada walxaha istiraatiijiga ah. Xalalkani waxay lagama maarmaan u yihiin ilaalinta waxqabadka chip, kordhinta cimriga alaabta, iyo hubinta isku halaynta aaladaha semiconductor.

Waanu kuu joognaa marka aad noo baahan tahay.

Fadlan buuxi foomka si aad nala soo xiriirto, waana ku faraxsanahay inaan ku caawinno.