Metallization teeb meem nyob rau hauv semiconductor ua, xws li electromigration thiab nce kev tiv thaiv, tuaj yeem degrade nti kev ua tau zoo thiab kev ntseeg tau. Cov teeb meem no feem ntau yog tshwm sim los ntawm qhov kub thiab txias thiab hloov microstructural. Cov kev daws teeb meem suav nrog kev tswj xyuas qhov kub thiab txias siv cov tshuab chillers, txhim kho kev sib cuag, thiab siv cov khoom siv siab heev.

Metallization Teeb meem nyob rau hauv Semiconductor Processing thiab yuav daws lawv li cas

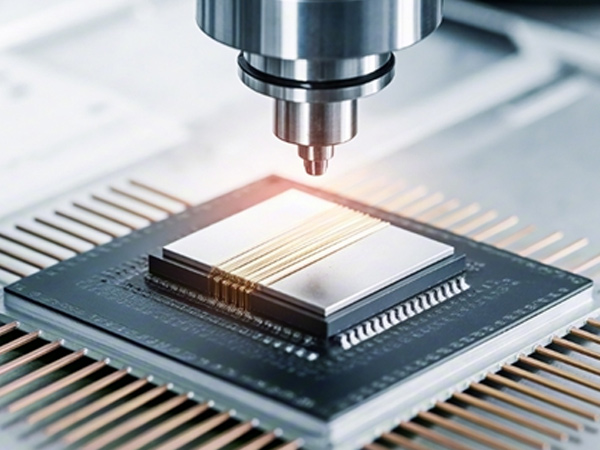

Metallization yog ib kauj ruam tseem ceeb hauv kev ua cov semiconductor, nrog rau kev tsim cov hlau sib txuas xws li tooj liab lossis txhuas. Txawm li cas los xij, teeb meem metallization-tshwj xeeb yog electromigration thiab kev tiv thaiv kev tiv thaiv-ua rau muaj teeb meem loj rau kev ua tau zoo thiab kev ntseeg siab ntawm kev sib koom ua ke.

Ua rau Metallization Teeb meem

Metallization teeb meem feem ntau tshwm sim los ntawm qhov kub thiab txias thiab microstructural hloov thaum lub sij hawm fabrication:

1. Kub kub ntau: Thaum lub sij hawm kub annealing, hlau interconnects muaj peev xwm muaj electromigration los yog ntau dhau lawm grain loj hlob. Cov kev hloov microstructural no cuam tshuam cov khoom hluav taws xob thiab txo qis kev sib txuas kev ntseeg siab.

2. Kev ntsuas kub tsis txaus: Yog tias qhov kub thiab txias tsawg dhau, qhov kev sib cuag ntawm cov hlau thiab silicon tsis tuaj yeem ua kom zoo, ua rau tsis zoo tam sim no, kev siv hluav taws xob ntau ntxiv, thiab qhov system tsis ruaj khov.

Kev cuam tshuam rau Chip Performance

Kev sib xyaw ua ke ntawm electromigration, kev loj hlob ntawm cov qoob loo, thiab kev tiv thaiv kev tiv thaiv tuaj yeem ua rau cov nti ua haujlwm tau zoo. Cov tsos mob muaj xws li cov teeb liab qeeb qeeb, kev ua yuam kev logic, thiab muaj kev pheej hmoo siab dua ntawm kev ua haujlwm tsis ua haujlwm. Qhov no thaum kawg ua rau cov nqi tu thiab txo cov khoom lag luam lub neej.

Kev daws teeb meem Metallization

1. Temperature Control Optimization: Ua raws li kev tswj xyuas thermal, xws li kev siv cov dej chillers qib industrial , pab tswj cov txheej txheem kub zoo ib yam. Cov cua txias ruaj khov txo qhov kev pheej hmoo ntawm electromigration thiab optimizes hlau-silicon tiv thaiv, txhim kho nti kev ua tau zoo thiab kev ntseeg tau.

2. Kev Txhim Kho Cov Txheej Txheem: Kho cov ntaub ntawv, tuab, thiab txoj kev tso tawm ntawm cov txheej tiv thaiv tuaj yeem pab txo qhov kev tiv thaiv. Cov txheej txheem xws li cov txheej txheem multilayer lossis doping nrog cov ntsiab lus tshwj xeeb txhim kho tam sim no ntws thiab ruaj khov.

3. Kev xaiv cov khoom siv: Siv cov hlau uas muaj zog tiv thaiv electromigration, xws li tooj liab alloys, thiab cov ntaub ntawv tiv tauj zoo xws li doped polysilicon lossis hlau silicides, tuaj yeem txo qis kev tiv thaiv thiab ua kom muaj kev ua haujlwm ntev.

Xaus

Metallization teeb meem nyob rau hauv semiconductor ua tau zoo mitigated los ntawm advanced kub tswj, optimized hu fabrication, thiab xaiv cov khoom siv tswv yim. Cov kev daws teeb meem no yog qhov tseem ceeb rau kev tswj xyuas cov chips kev ua tau zoo, txuas ntxiv cov khoom lag luam, thiab ua kom muaj kev ntseeg siab ntawm cov khoom siv semiconductor.

Peb nyob ntawm no rau koj thaum koj xav tau peb.

Thov ua kom tiav daim foos tiv tauj peb, thiab peb yuav zoo siab los pab koj.