Kamar yadda muka sani, PCB shine "gada" don haɗa kowane kayan lantarki kuma shine babban sashi a cikin kayan lantarki. Yana da aikace-aikace iri-iri, ciki har da na'urorin lantarki, na'urorin lantarki na mota, sadarwa, magani, aikin soja, sararin samaniya da sauransu. A zamanin yau, masu amfani da lantarki da na'urorin lantarki na mota suna samun ci gaba mafi sauri kuma sun zama manyan filayen aikace-aikace. A wannan lokacin, walda na PCB ya jawo hankalin manyan masana'antun PCB. Don haka, menene nau'ikan PCB na iya yin aikin walda injin laser? Bari mu duba a hankali a kasa.

1.A abu yana bukatar zama weldable

Yana nufin cewa a ƙarƙashin yanayin da ya dace, ƙarfen da za a -- narkar da gwangwani na iya haɗuwa tare don samun ingantaccen ingancin gami. Ba kowane karfe yana da kyakkyawan walƙiya ba. Don inganta weldability na karfe, masu amfani za su iya yin tin-plating ko azurfa-plating a kan karfe don hana hadawan abu da iskar shaka daga cikin karfe surface.

2.Abin yana buƙatar zama mai tsabta a saman

Domin hada gwangwanin sayar da kayan da za a narke, ana bukatar a tsaftace saman abin. Ko da kyawawan abubuwan waldawa, fim ɗin iskar shaka ko tabon mai na iya faruwa a saman abin. Don haka, don tabbatar da ingancin walda, farfajiyar abu dole ne ya kasance mai tsabta.

3.Yi amfani da foda mai ƙima mai dacewa

Manufar sikelin foda shine don cire fim ɗin oxidation akan abin da za a yi waldi. Daban-daban dabarun walda ya kamata a yi amfani da daban-daban sikelin foda. Domin walda madaidaicin kayan lantarki kamar PCB, rosin yakamata a yi amfani dashi azaman foda don tabbatar da amincin walda.

4.Abin yana buƙatar zafi zuwa zafin jiki mai dacewa

Idan zafin walda ya yi ƙasa da ƙasa, ba za a iya samar da gami ba. Kuma idan zafin walda ya yi yawa, waldawar juzu'in za ta kasance a cikin yanayin da ba na eutectic ba, wanda zai rage ingancin walda kuma a cikin mafi munin yanayin, kushin akan PCB zai ragu.

5.The waldi na bukatar dace lokaci lokaci

Lokacin walda yana nufin lokacin da aka kashe a cikin sinadarai da halayen jiki a cikin aikin walda. Bayan yanke shawarar zafin walda, masu amfani yakamata su yanke shawarar lokacin walda mai dacewa dangane da siffa, inganci da halayen abubuwan da za a yi walda. Idan lokacin walda ya yi tsayi da yawa, abubuwan da aka gyara ko sassan da aka haɗa suna da sauƙin lalacewa. Gabaɗaya magana, kowane wuri bai kamata ya ɗauki fiye da daƙiƙa 5 a lokaci ɗaya ba.

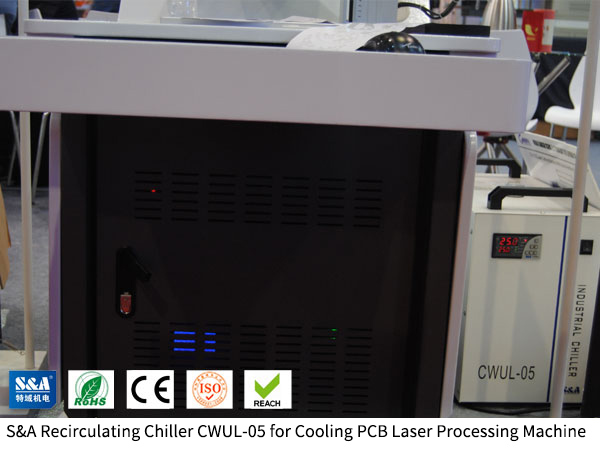

Domin kiyaye injin walda Laser na PCB a mafi kyawun sa, yana buƙatar sanyaya shi da kyau ta hanyar chiller masana'antu. S&A Teyu ya kasance yana sadaukar da kai ga firiji na masana'antu tsawon shekaru 19 kuma yana iya ba da chillers masana'antu don nau'ikan injunan waldawa na Laser daban-daban. Chillers masu sake zagayawa suna nuna sauƙin amfani, ƙarancin kulawa, tsawon rayuwar sabis, amincin da bai dace ba. Ƙarfin sanyaya ya tashi daga 0.6KW zuwa 30KW, wanda zai iya biyan bukatun sanyaya daga masu amfani daban-daban. Idan ba ku da tabbacin yanayin sake zagayawa don zaɓar, yi mana imel kawai marketing@teyu.com.cn